Production method of light-metal composite plating steel strip for top-grade doors and windows

A composite coating and production method technology, applied in metal material coating process, coating, sputtering coating and other directions, can solve the problems of insufficient mechanical properties, poor wear resistance, low strength, etc., and achieve good stamping and welding performance. , good surface performance and corrosion resistance, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below:

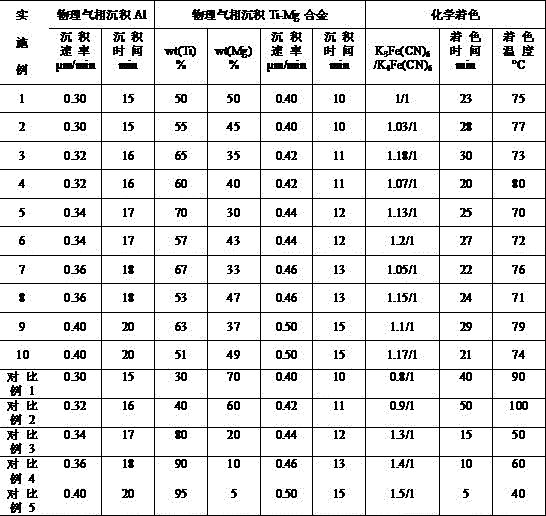

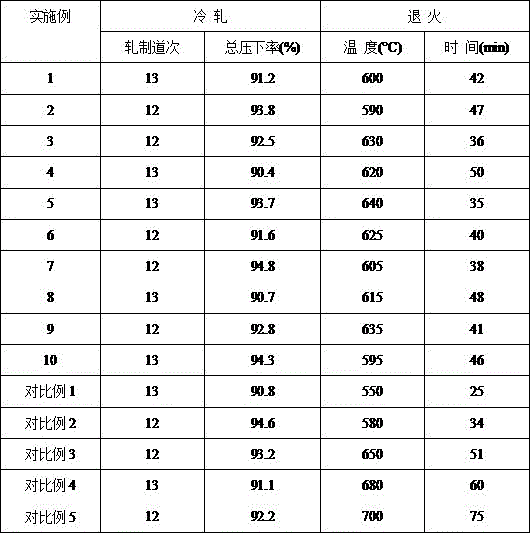

[0029] Table 1 is the list of cold rolling process parameters of each embodiment of the present invention and comparative example;

[0030] Table 2 is the tape making process parameter list of each embodiment of the present invention and comparative example;

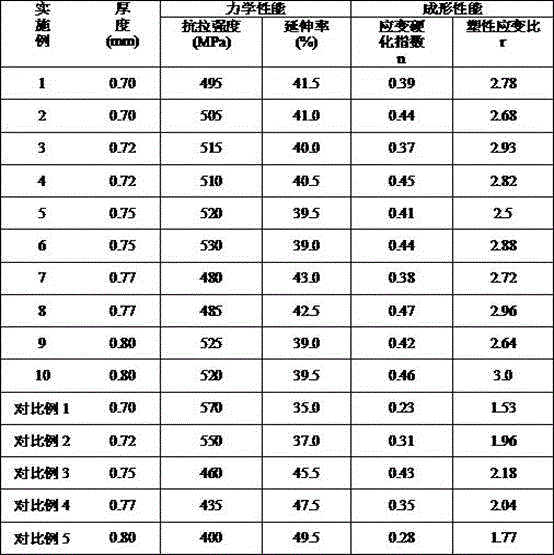

[0031] Table 3 is a product performance list of each embodiment of the present invention and comparative examples.

[0032] Each embodiment of the present invention is produced according to the following steps:

[0033] 1) Carry out the cold rolling process:

[0034] A. Using ordinary Q215 hot-rolled pickled coil as raw material, carry out 12 or 13 times of cold rolling and repeated rolling, control the total reduction rate to 90~95%, and then routinely degrease;

[0035] B. Annealing is carried out under an all-hydrogen protective atmosphere, the annealing temperature is controlled to be 590~640 °C, and the holding time is 35~50 min;

[0036] 2) Carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com