Double-layer winding-soldering pipe production technology for connection of indoor/outdoor unit of air conditioner

A technology of double-layer rolled welded pipe and air conditioner chamber, which is applied in the field of manufacturing engineering, can solve the problems of low yield strength and achieve the effects of low yield strength, soft hand feeling and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

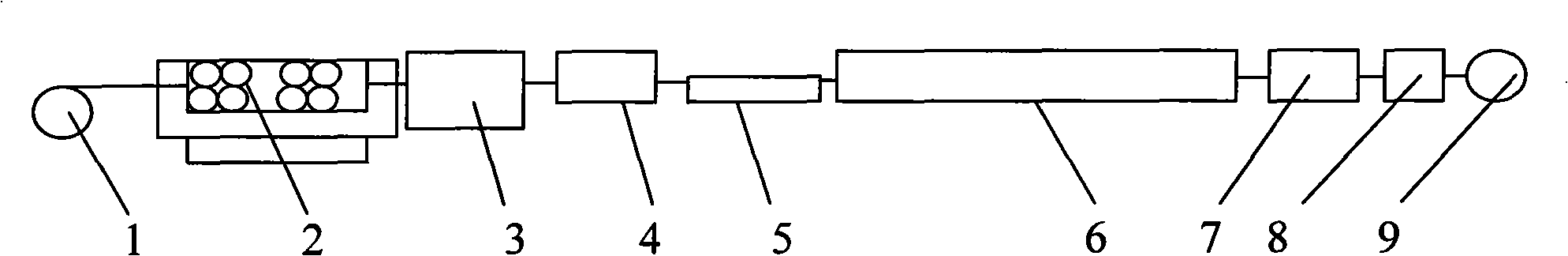

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] see figure 1 , the present invention produces the copper-plated steel strip of double-layer coil welded pipe and selects ultra-low carbon interstitial-free steel [W(C)3 Decompose the protective gas pipeline valve, fill the brazing furnace 3, the closed pipeline 4, the stainless steel pipe 5, with NH 3 Decompose the protective gas; start the production line, adjust the temperature of the brazing furnace 3 to 1084°C + 30°C for brazing with copper as the brazing material, and send the brazed double-layer coiled pipe into the internal passage NH 3 In the closed cooling pipe 4 that decomposes the protective gas, the outside of the pipe (4) is cooled with circulating water, so that the temperature of the double-layer coiled welded pipe can be quickly cooled below the melting point of copper, preventing the occurrence of copper nodules, and ensuring the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com