A kind of hot-dip galvanized steel sheet with a yield strength of 550mpa and its production method

A technology of hot-dip galvanized steel sheet and yield strength, applied in hot-dip galvanizing process, coating, metal material coating process, etc. Strength fluctuation and other problems, to achieve the effect of good strength and toughness, high strength, improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

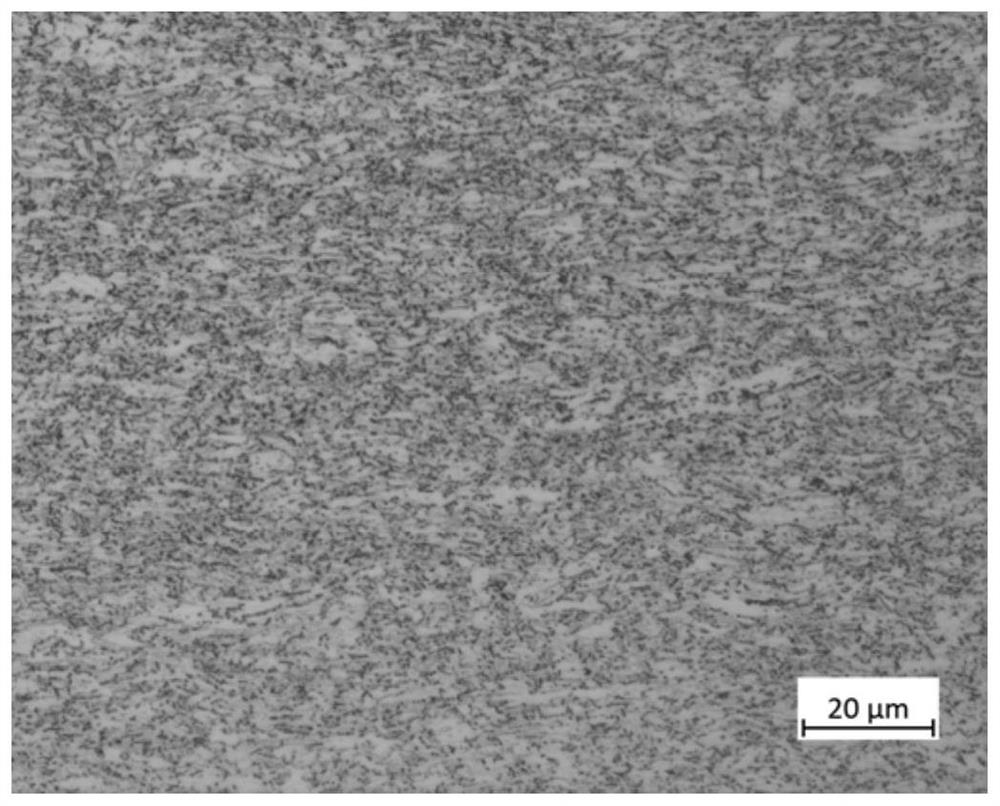

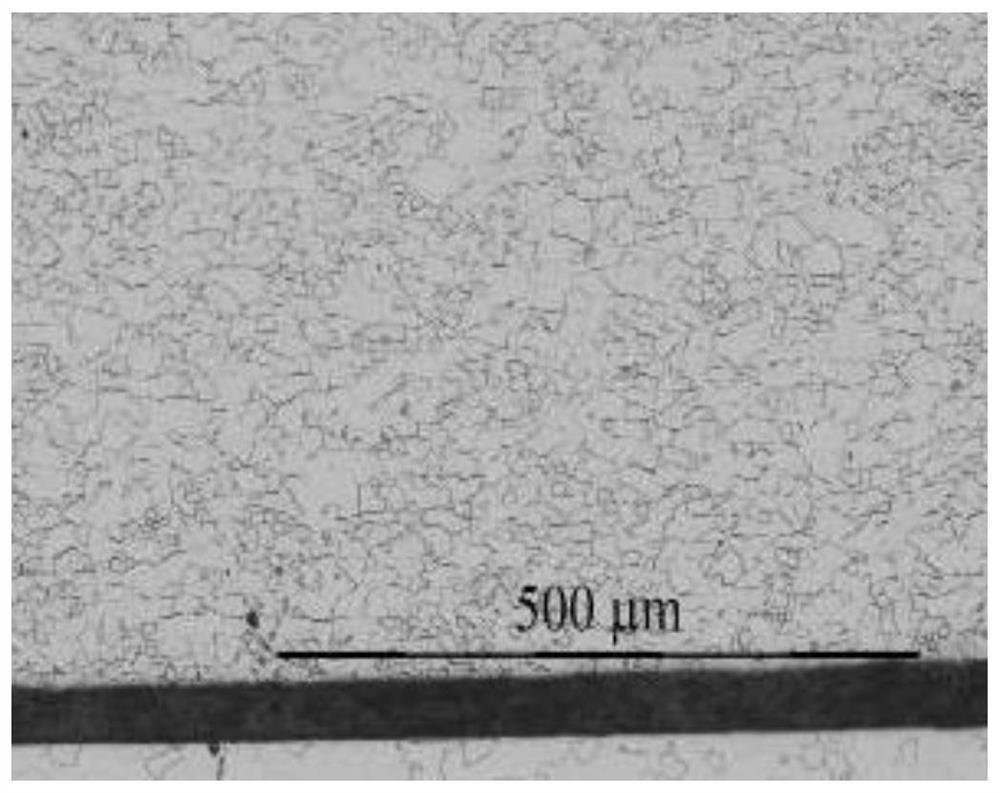

Image

Examples

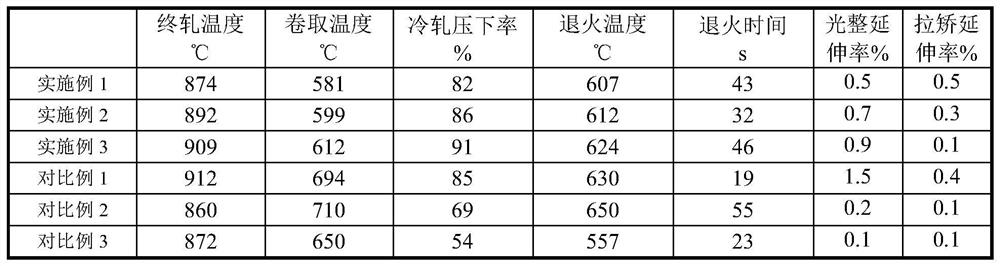

Embodiment 1

[0063] The chemical composition of the steel plate in this example is: C 0.008%, Si≤0.009%, Mn 0.19%, P0.012%, S 0.016%, Als 0.022%, Ti 0.032%, Nb 0.043%, N 0.0028%, O 0.0019 %, Cu0.030%, Cr 0.010%, and the rest are iron and other impurities. The finishing temperature of hot rolling is 874°C, the coiling temperature is 581°C; the reduction rate of cold rolling is 82%; when galvanizing, the annealing temperature T of the RTF section is 607°C, the annealing time t is 43s, and the skin elongation is 0.5% , Tensile straightening elongation 0.5%.

Embodiment 2

[0065] The chemical composition of the steel plate in this example is: C 0.010%, Si≤0.006%, Mn 0.10%, P0.008%, S 0.010%, Als 0.005%, Ti 0.001%, Nb 0.060%, N 0.0026%, O 0.0016 %, Cu0.045%, Cr 0.022%, and the rest are iron and other impurities. The finishing temperature of hot rolling is 892°C, the coiling temperature is 599°C; the reduction rate of cold rolling is 86%; when galvanizing, the annealing temperature T of the RTF section is 612°C, the annealing time t is 32s, and the skin elongation is 0.7% , Tensile straightening elongation 0.3%.

Embodiment 3

[0067] The chemical composition of the steel plate in this example is: C 0.006%, Si≤0.008%, Mn 0.30%, P0.009%, S 0.005%, Als 0.070%, Ti 0.080%, Nb 0.001%, N 0.0015%, O 0.0017 %, Cu0.060%, Cr 0.040%, and the rest are iron and other impurities. The finishing temperature of hot rolling is 909°C, the coiling temperature is 612°C; the reduction rate of cold rolling is 91%; when galvanizing, the annealing temperature T of the RTF section is 624°C, the annealing time t is 46s, and the skin elongation is 0.9% , Tensile straightening elongation 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com