Steel plate with axial bearing capacity and excellent formability used for cans and manufacturing method thereof

A bearing capacity and formability technology, which is applied to steel plates with high axial bearing capacity and excellent formability for tanks and their manufacturing fields, can solve the problems of rising material yield strength, affecting strength, and high manufacturing costs, and achieve high strength and strain. Hardening index, increase axial bearing capacity, no slip line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

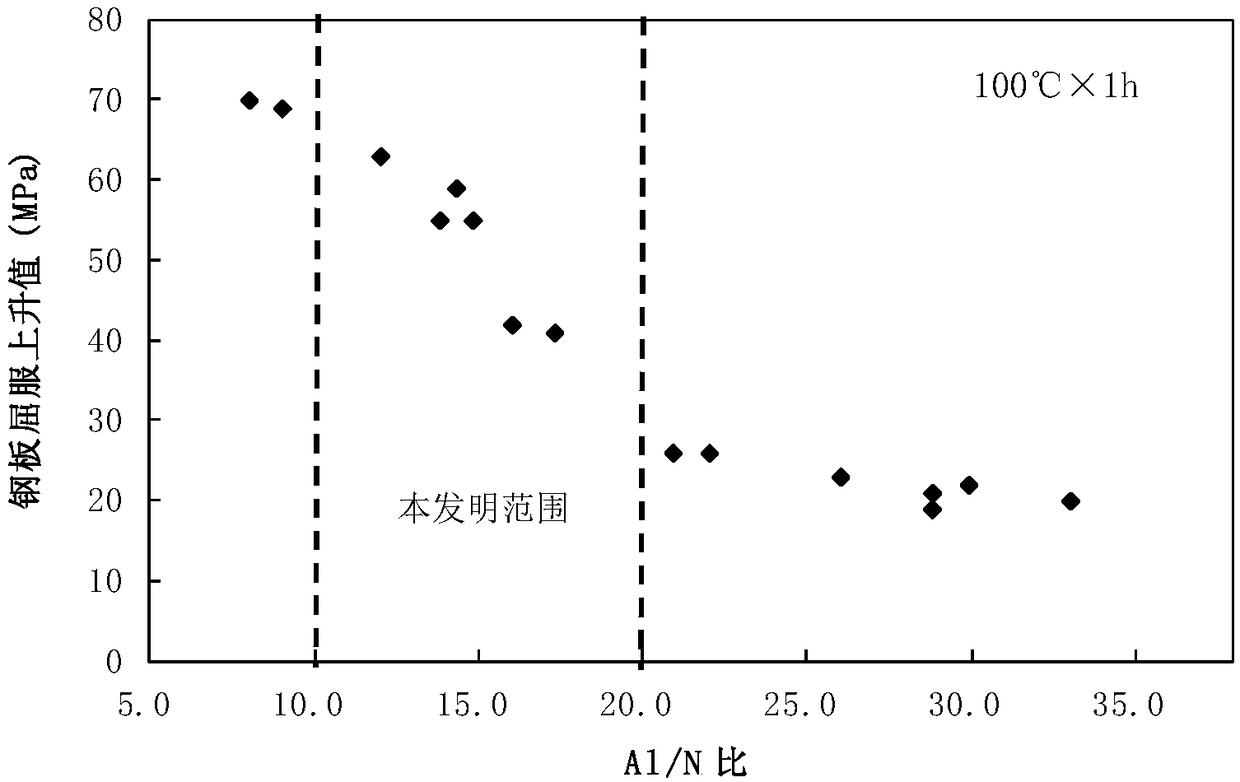

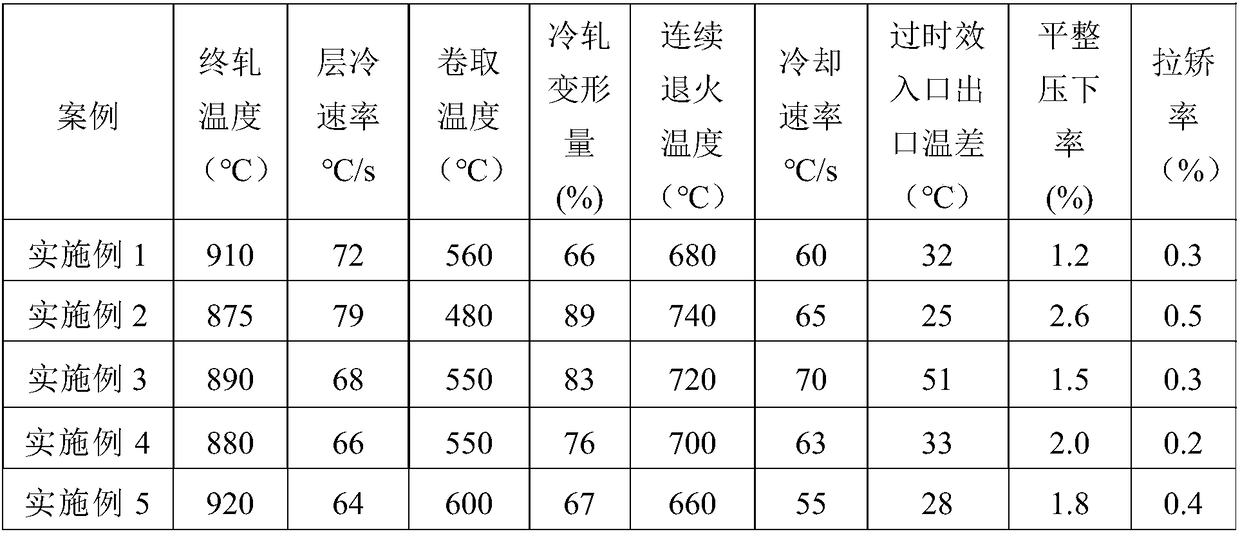

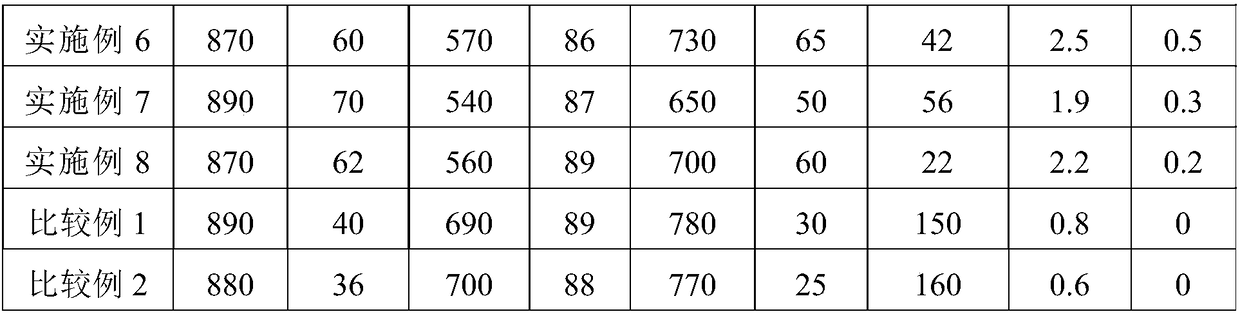

[0035] The chemical compositions of the examples and comparative examples of the present invention are shown in Table 1, the process parameters of hot rolling and cold rolling are shown in Table 2, and the material properties and service characteristics are shown in Table 3.

[0036] Table 1 Unit: weight percentage

[0037] the case

C

Si

mn

P

Al

N

Al / N

Example 1

0.025

0.018

0.68

0.008

0.031

0.0028

11.1

Example 2

0.066

0.020

0.23

0.013

0.038

0.0023

16.5

Example 3

0.035

0.028

0.24

0.011

0.030

0.0021

14.1

Example 4

0.073

0.006

0.86

0.010

0.072

0.0039

18.5

Example 5

0.051

0.012

0.37

0.017

0.041

0.0035

11.7

Example 6

0.028

0.024

0.51

0.018

0.060

0.0042

14.3

Example 7

0.039

0.013

0.72

0.006

0.051

0.0037

13.7

Example 8

0.022

0.019

0.62

0.010...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com