Polyurethane Elastomers for Subsea Pipeline Insulation

A technology of polyurethane elastomers and insulating materials, applied in the field of polyurethane elastomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

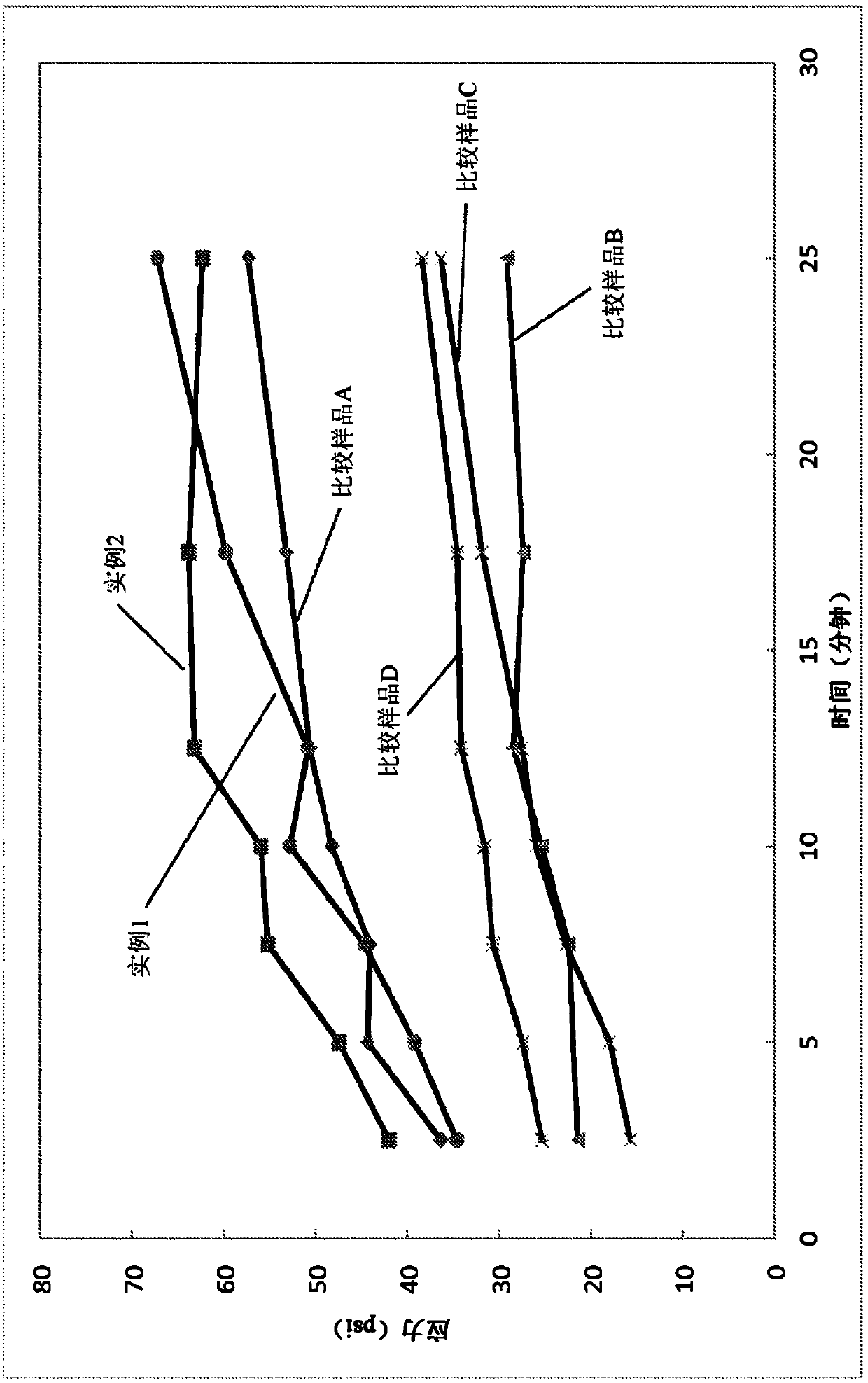

[0070] Examples 1 and 2 performed similarly or better than Comparative Sample A. After 2.5 minutes, the compressive strength of Example 1 was 4 psi to -5 psi (27 kPa to 35 kPa) higher than Comparative Sample 1 and remained higher throughout cure. Example 2 shows the effect of adding a small amount of epoxy resin to the formulation of the invention. At 2.5 minutes, the compressive strength was almost equal to that of Comparative Sample A and was easily exceeded during the later stages of curing.

[0071] Comparative Sample B shows the effect of replacing the mercury catalyst system with a blocked amidine. The compressive strength at 2.5 minutes is only about 20 psi (138 kPa), which represents an almost 50% drop compared to Comparative Sample A, and the compressive strength continues to build very slowly. This means that the block amidine catalyst is not nearly as good as the mercury catalyst system.

[0072] Comparative Sample C and Comparative Sample D show the effect of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com