Ultra-deep-draw Ti-IF steel cold rolling and annealing process

An annealing process and ultra-deep drawing technology, applied in the field of metallurgy, can solve problems such as being unsuitable for large-scale industrial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Put the slab to be rolled into the heating furnace, the chemical composition and weight percentage of the slab are: C 0.0045%, Mn 0.14%, P0.009%, S 0.0035%, Ti 0.062%, N0.004%, The rest is Fe and undetectable trace impurities.

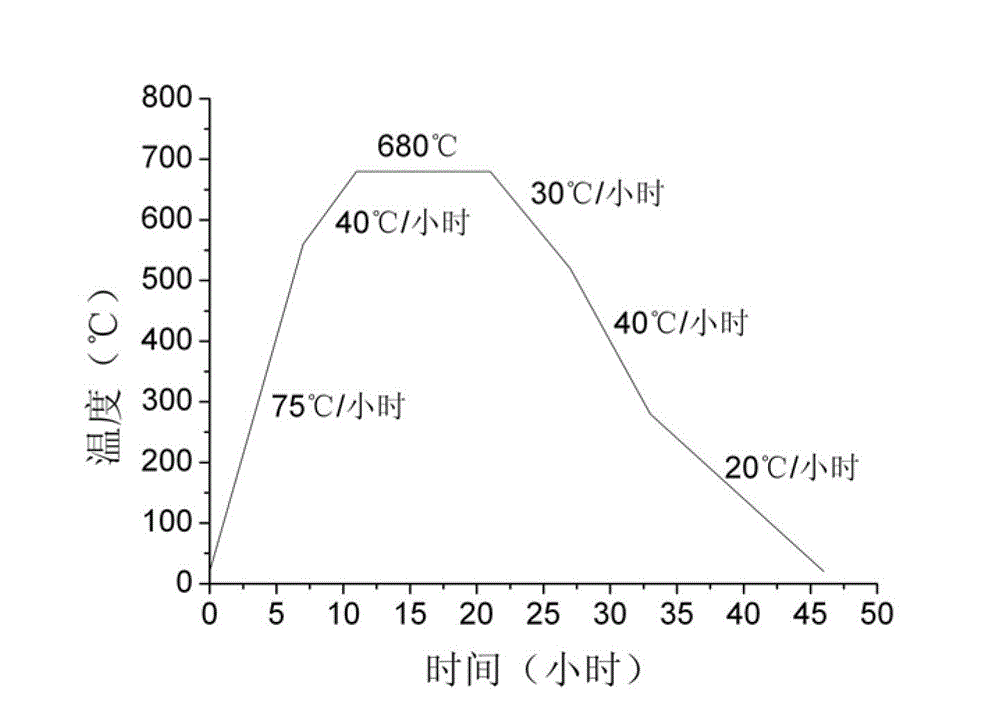

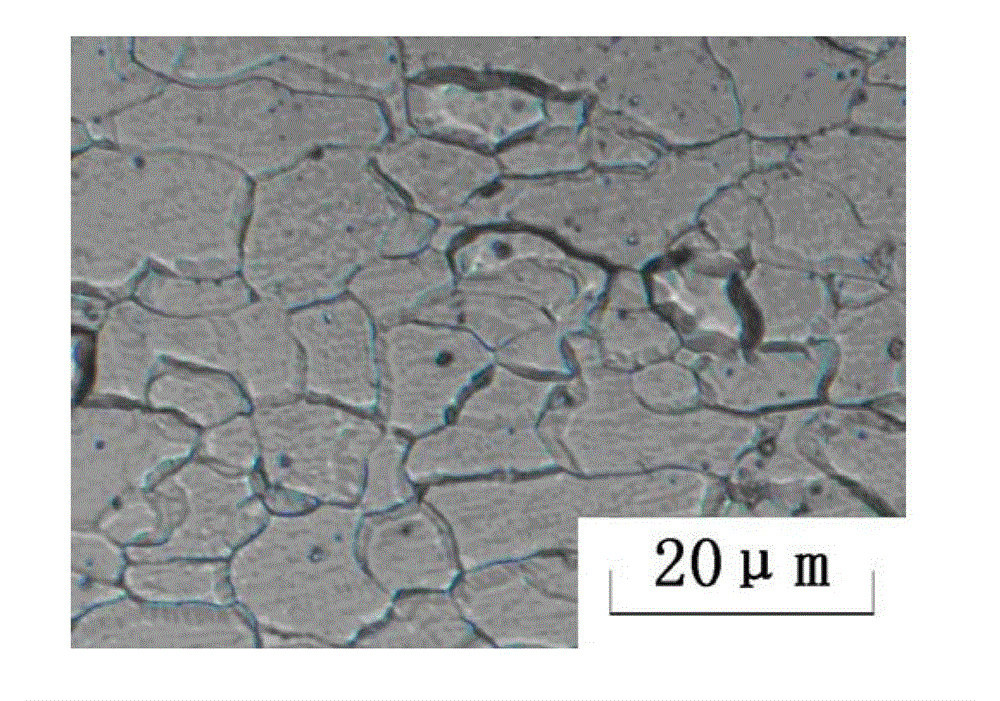

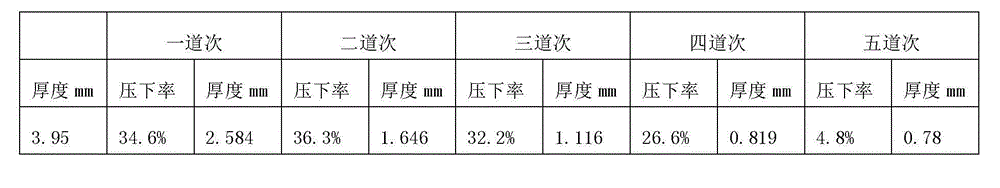

[0012] The total reduction in the five cold rolling passes is 80%, and the reductions in each pass are 34.6%, 36.3%, 32.2%, 26.6%, and 4.8%, respectively, as shown in Table 1. The entrance rolling rate and the exit rolling rate are respectively is 121m / min and 612m / min; the inlet extension and outlet extension are 260KN and 29KN respectively, see Table 2. The annealing process is as follows: two-stage heating, the heating rates are 75°C / hour and 40°C / hour, the annealing temperature is 680°C, the holding time is 11 hours, three-stage cooling is adopted, the cooling rates are 30°C / hour, 40°C / hour, respectively. °C / hour, 20°C / hour. The mechanical property test values of the IF steel samples treated according to the above process are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com