Drawing mechanism

A technology of depth and mold components, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unfavorable material forming performance and stability of stripping, and achieve good drawing performance, stable stripping process, and increased The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples shown in the drawings.

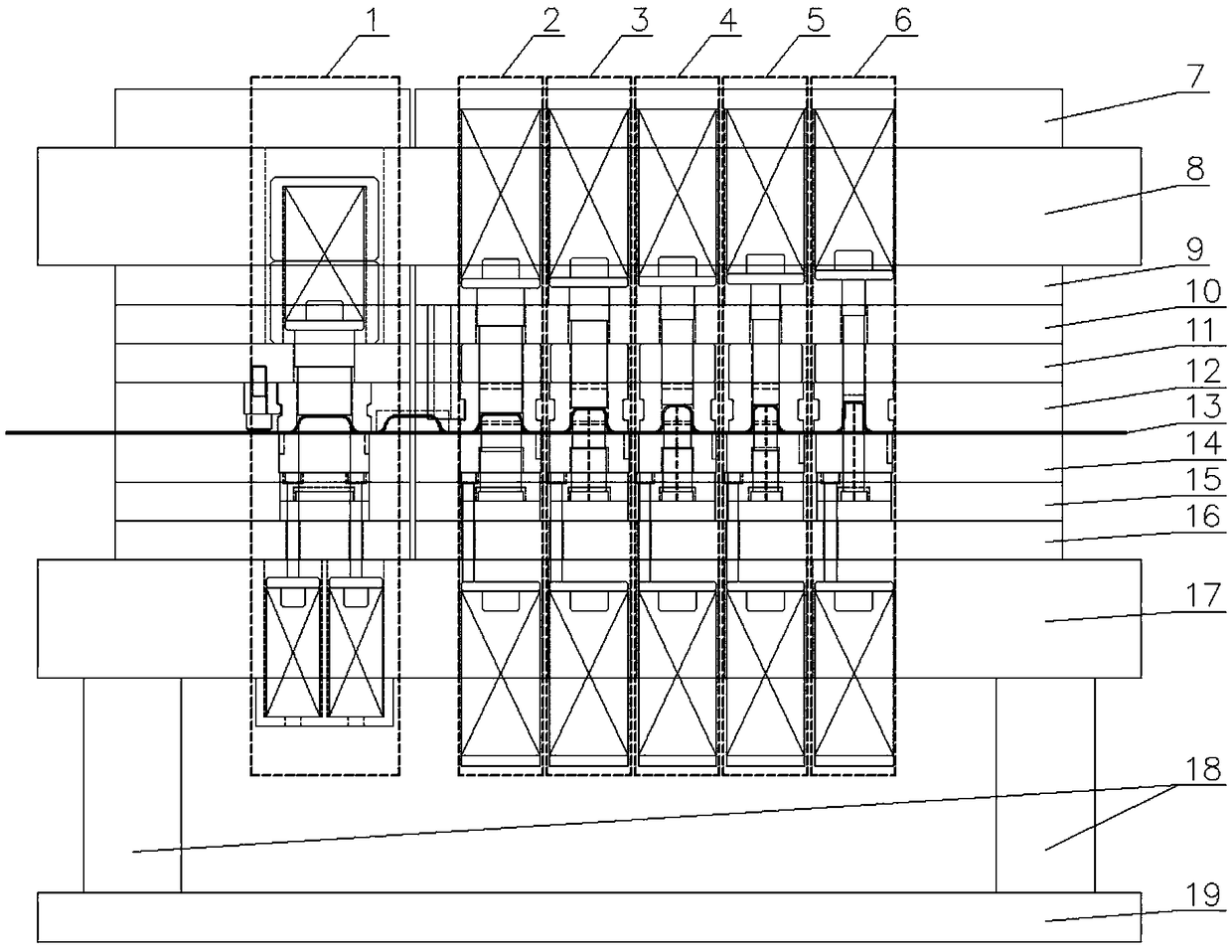

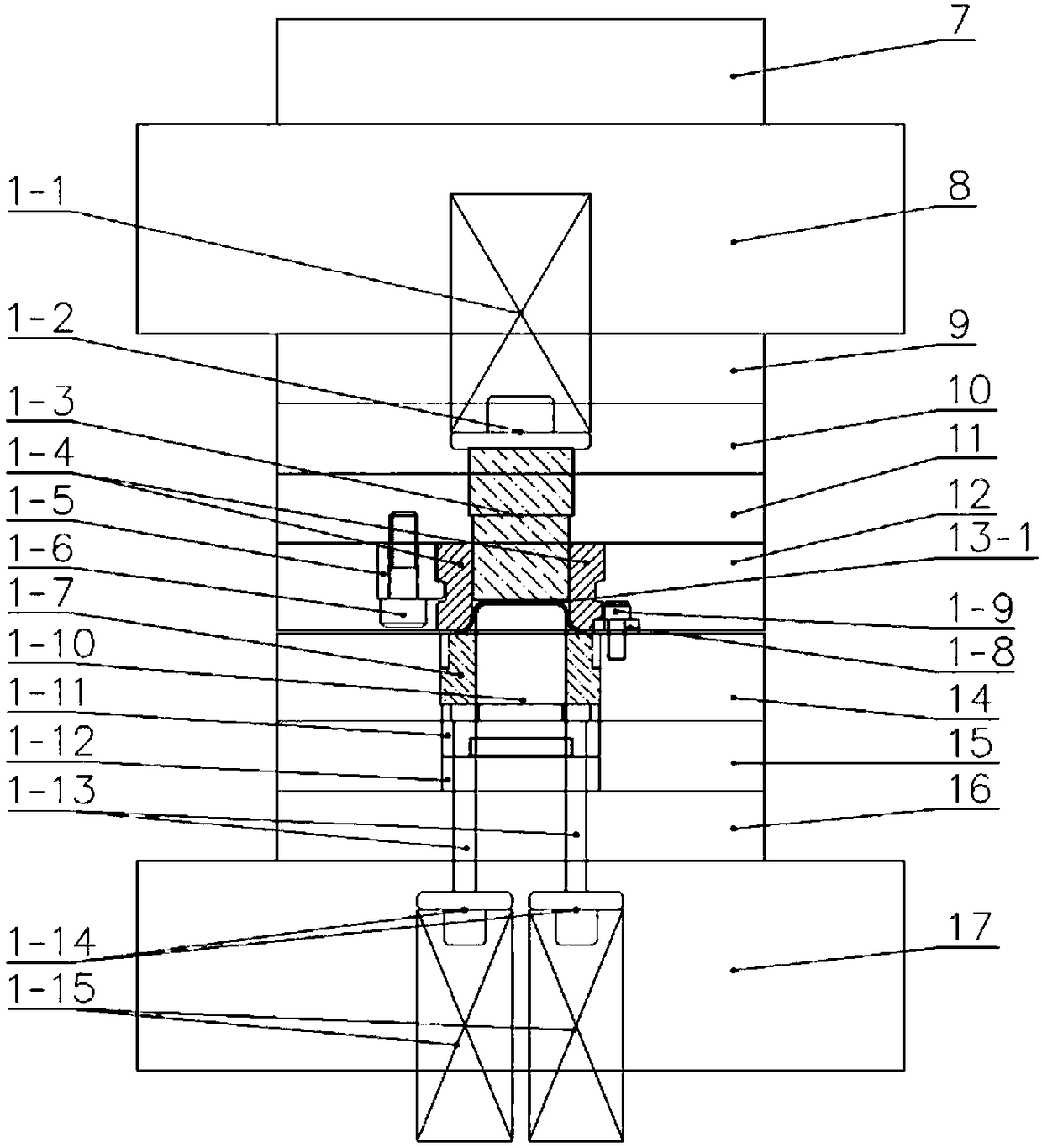

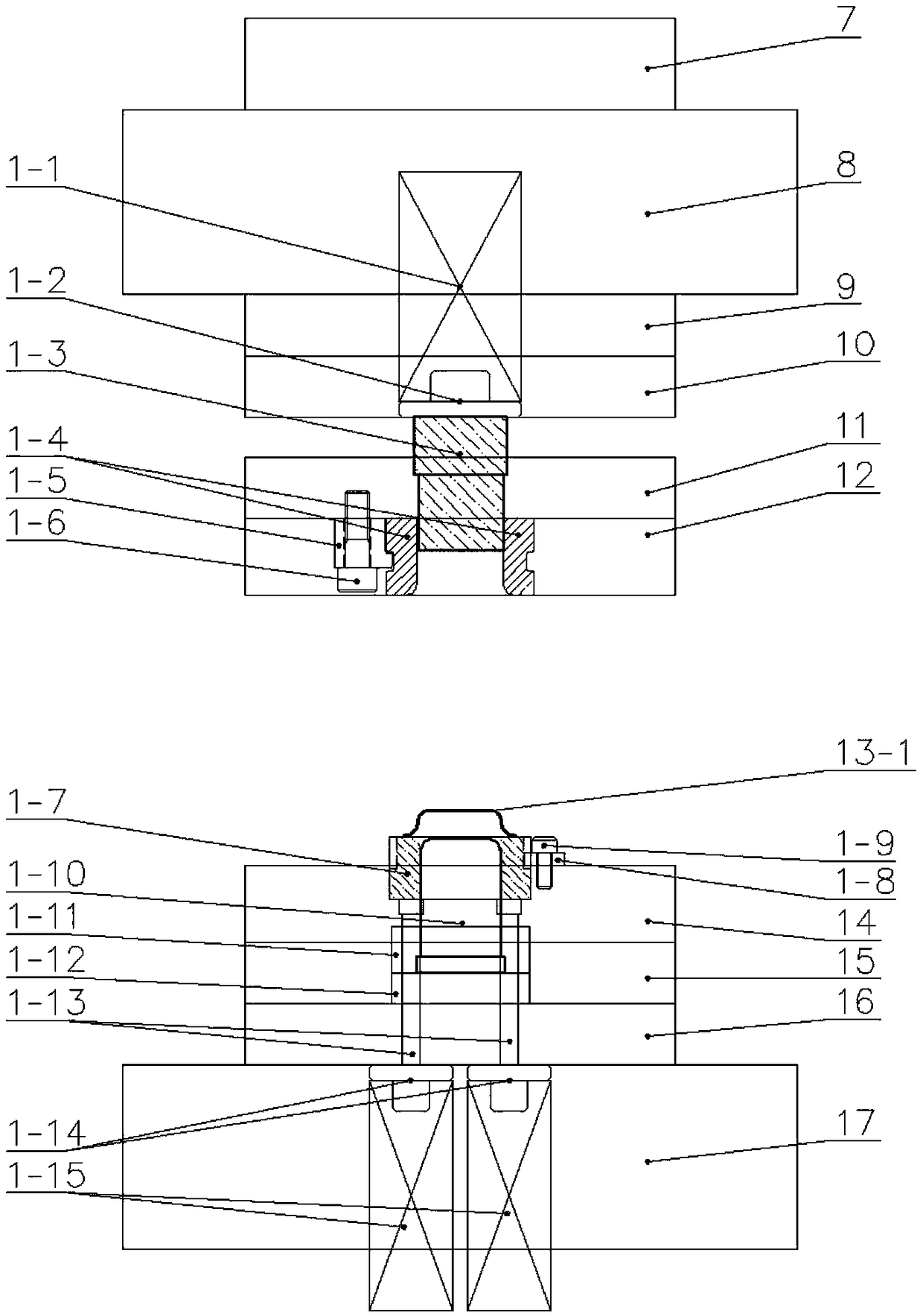

[0025] The drawing mechanism is used to deepen the plate into a product with a cylindrical groove. The groove is cylindrical and has a certain depth and inner diameter. The drawing mechanism includes an upper mold assembly, a lower mold assembly, and a The drawing parts in the upper film assembly and the lower die assembly, each of the drawing parts includes an upper drawing assembly and a drawing drawing assembly respectively provided in the upper die assembly and the lower die assembly, each The upper drawing assembly includes an upper mold stripping mechanism arranged in the upper mold assembly and a drawing ring sleeved on the upper mold stripping mechanism and fixed in the upper mold assembly. There is a deep-drawn fillet connecting area with an arc transition between the lower end surface of the deep ring and its inner side wall. The inner side wall from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com