Manufacturing method for reducing anisotropism of pure-titanium sheet strip for deep drawing

A technology of anisotropy and manufacturing method, applied in the field of metallurgy, can solve the problems of ear making and wrinkling, and achieve the effect of good deep drawing performance and low product anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

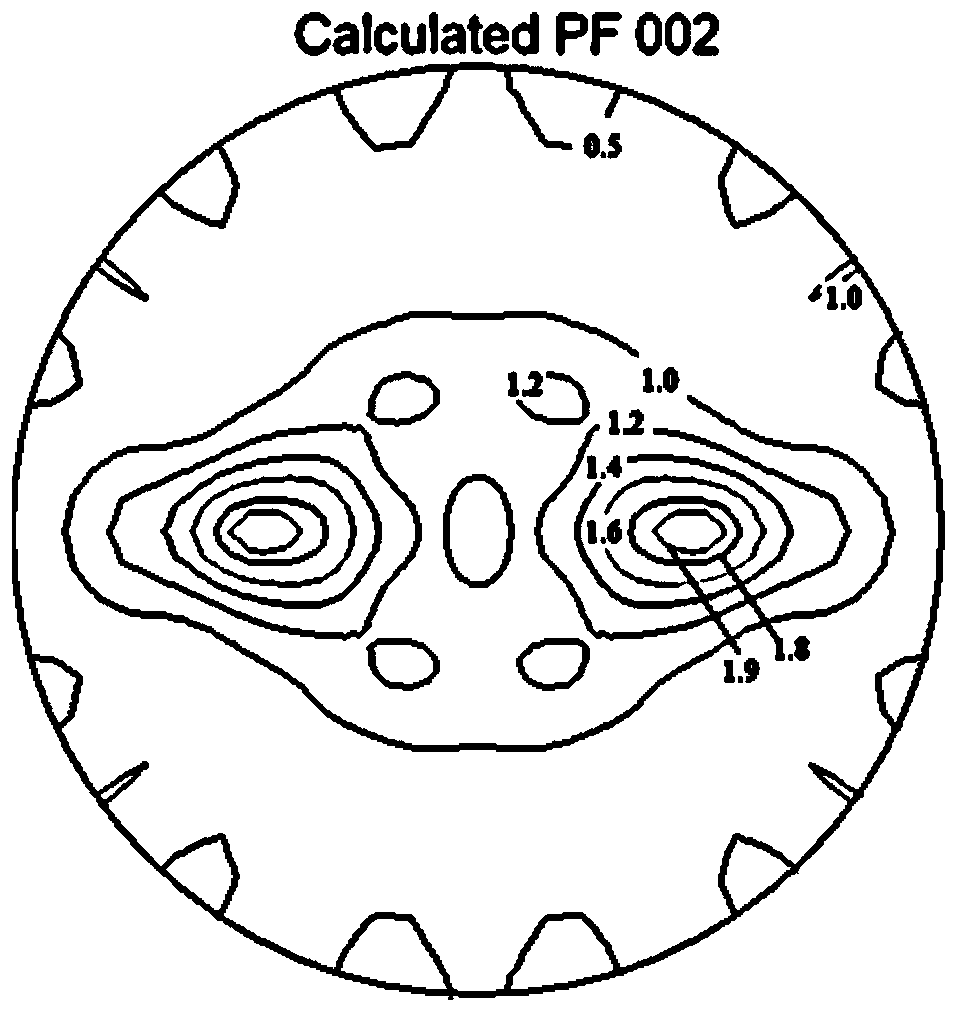

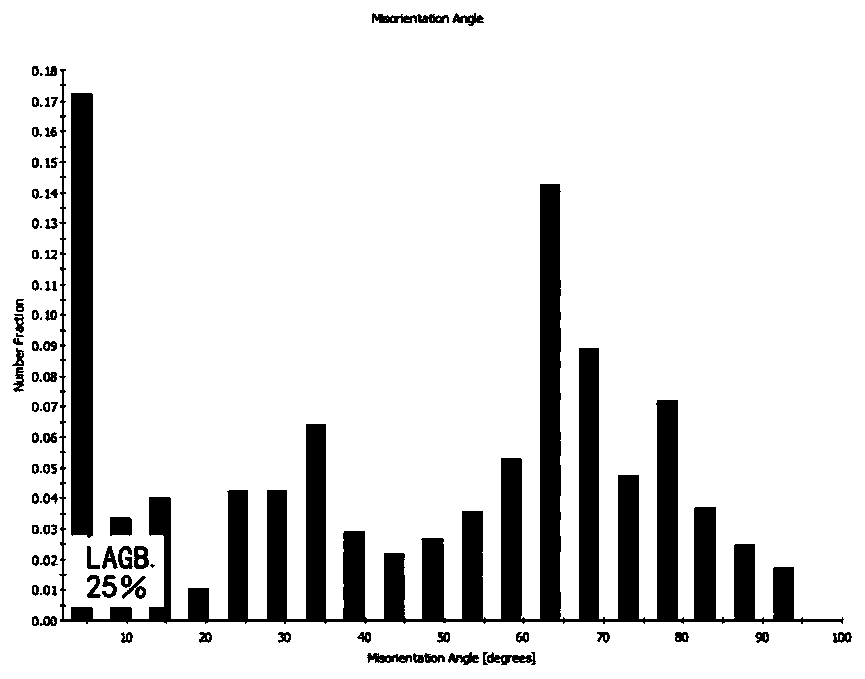

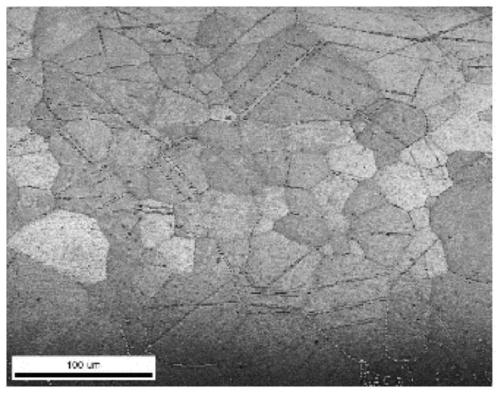

Image

Examples

Embodiment 1

[0021] Hot-rolled TA1 industrial pure titanium strip with a thickness of 3.5mm, the mass fraction of each chemical composition is: C≤0.07%; N≤0.05%; O≤0.11%; H≤0.015%; Fe≤0.15%; other elements ≤0.40 %; the balance is titanium. Its α→β phase transition temperature is 890°C.

[0022] The steps adopted in the manufacturing method for reducing the anisotropy of the pure titanium sheet strip for deep drawing include:

[0023] Take the above-mentioned hot-rolled TA1 industrial pure titanium strips a, b and c whose surfaces have been pickled by shot blasting, and send the three pieces to the cold rolling mill for unidirectional longitudinal rolling respectively to form an intermediate billet with a thickness of 1.1 mm. The intermediate billet is heat treated separately: the intermediate billet a (process 1) is heated to 650°C for recrystallization and annealed, and then rapidly gas-cooled in a protective atmosphere; the intermediate billet b (process 2) is heated to 920°C, held for ...

Embodiment 2

[0029] TA1 industrial pure titanium strip with a thickness of 4.0mm after hot rolling, shot blasting and pickling, the mass fraction of each chemical component is: C≤0.08%; N≤0.05%; O≤0.10%; H≤0.010%; Fe≤0.12%; other elements≤0.40%; the balance is titanium. Its α→β phase transition temperature is 895°C.

[0030] The steps adopted in the manufacturing method for reducing the anisotropy of the pure titanium sheet strip for deep drawing include:

[0031] Take three qualified cold-rolled TA1 billets d, e and f, and send them into a cold rolling mill for unidirectional longitudinal rolling to a thickness of 1.6mm. The intermediate billet is heat treated separately: the intermediate billet d (process 4) is heated to 650°C for recrystallization annealing, and then gas-cooled under a protective atmosphere; the intermediate billet e (process 5) is heated to 900°C, held for 1 to 10 minutes, and then gas-cooled; The intermediate billet f (process 6) adopts two heat treatments, each tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com