Method for manufacturing superlarge spherical seal head

A technology of spherical head and manufacturing method, which is applied in the direction of manufacturing tools, sealing, nuclear power generation, etc., can solve problems such as wrinkling, lower molding quality, and large lower spherical surface, so as to achieve the effect of not being easily deformed and ensuring installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

[0021] The present invention can be used in the manufacture of various spherical heads, such as standard elliptical heads, dished heads and the like.

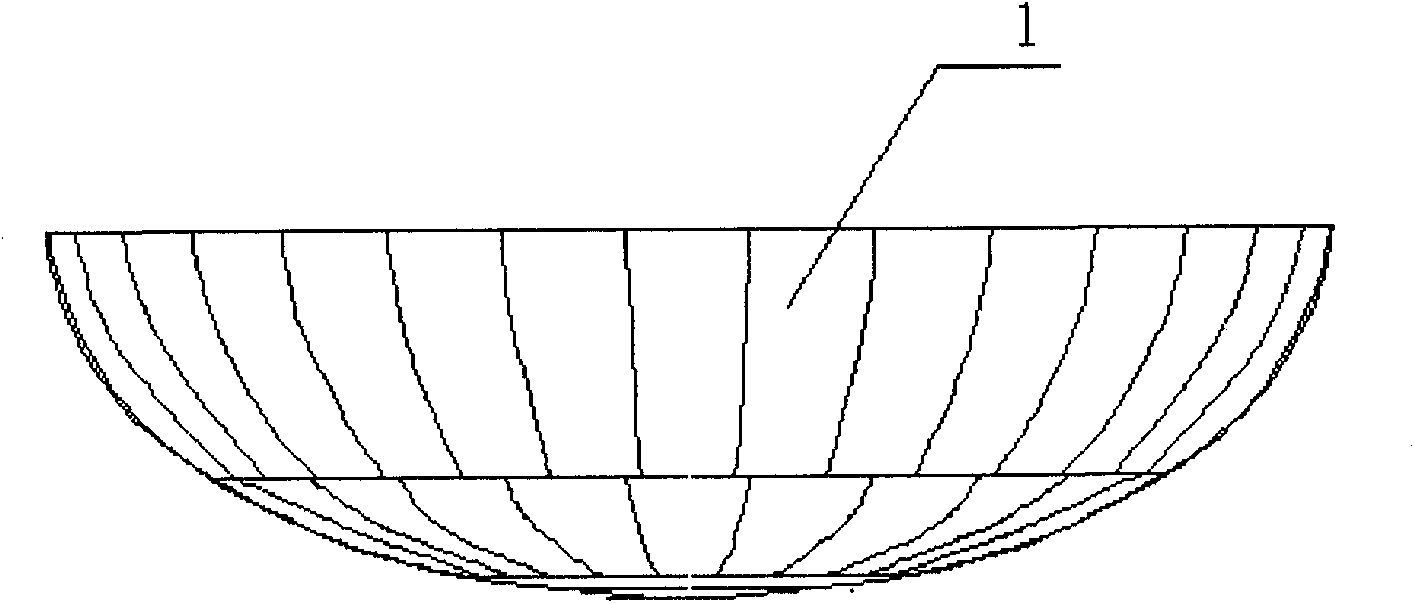

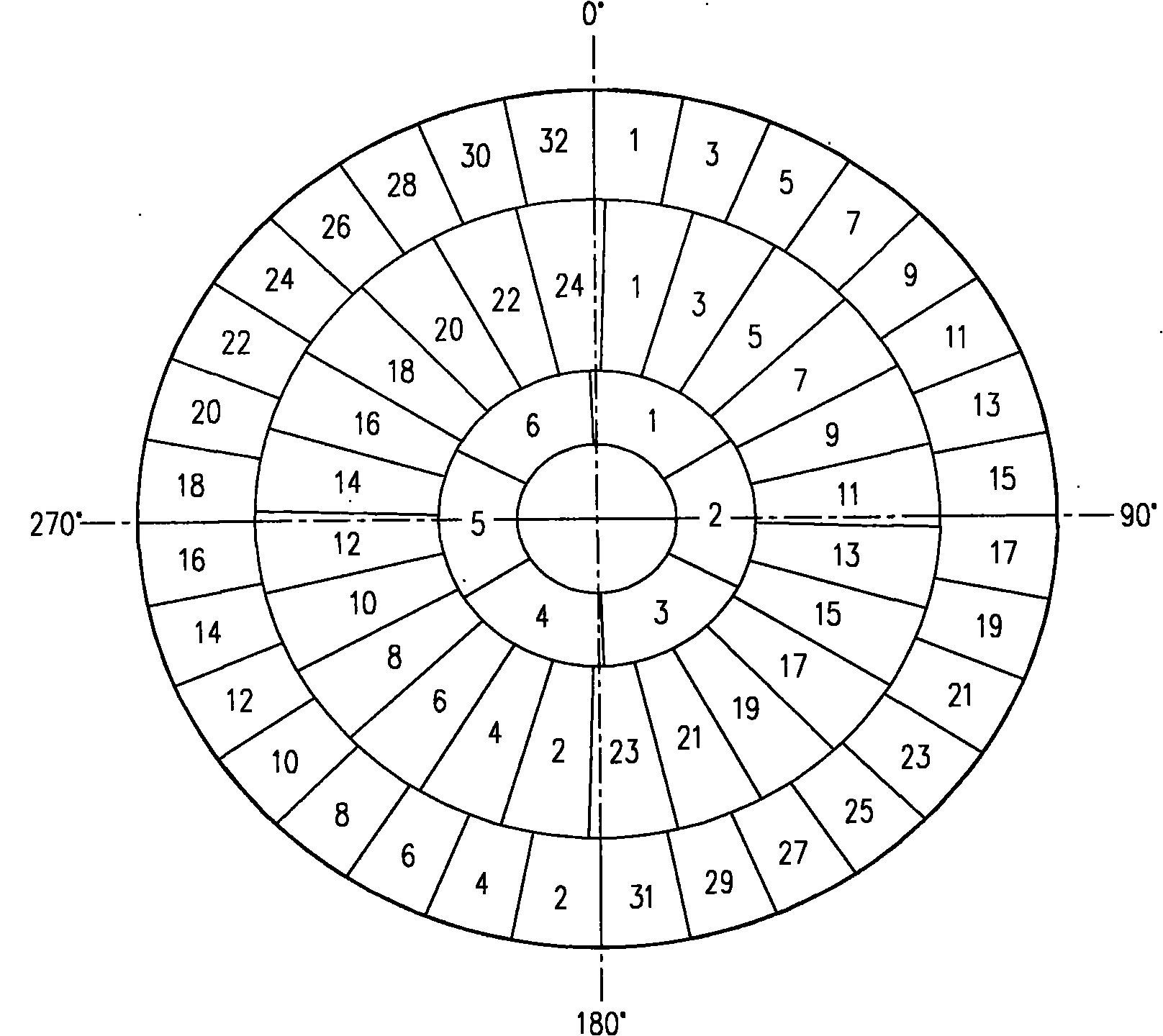

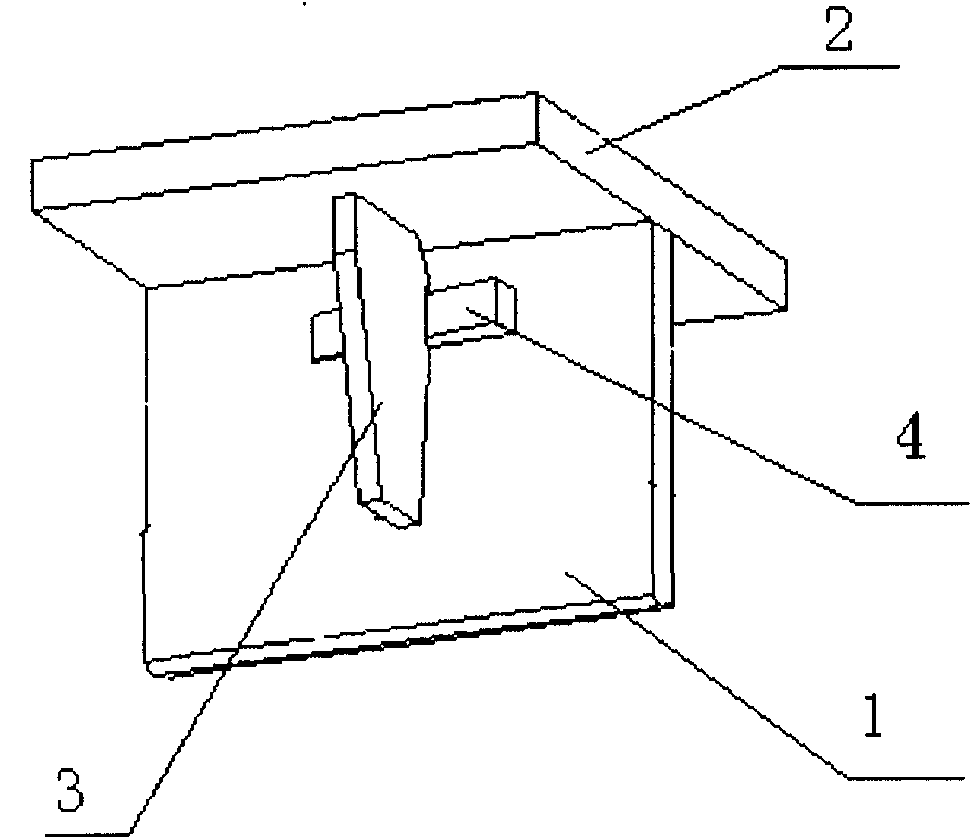

[0022] As an example, the head of the present invention is tailor-welded from a total of 64 steel plates in four ring parts. Each steel plate can be pressed into a predetermined shape by a hydraulic press.

[0023] see figure 1 and 2 , The spherical head is formed by four ring parts from the top of the ball (closed end) to the opening (open end). The first ring portion forms the closed end of the head and comprises two steel plates. The second ring part and the third ring part form the middle ring part of the head, including 6 steel plates and 24 steel plates respectively. The fourth ring part forms the open end of the head and consists of 32 steel plates.

[0024] The following examples illustrate the head manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com