Copper aluminum composite pipes shaping method

A technology of copper-aluminum composite and copper tube, which is applied in the direction of metal extrusion mandrel, etc., can solve the problems that bimetallic composite tubes cannot be made of copper-aluminum composite tubes, bimetallic tubes are difficult to form, etc., and achieve good application prospects, continuous production, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

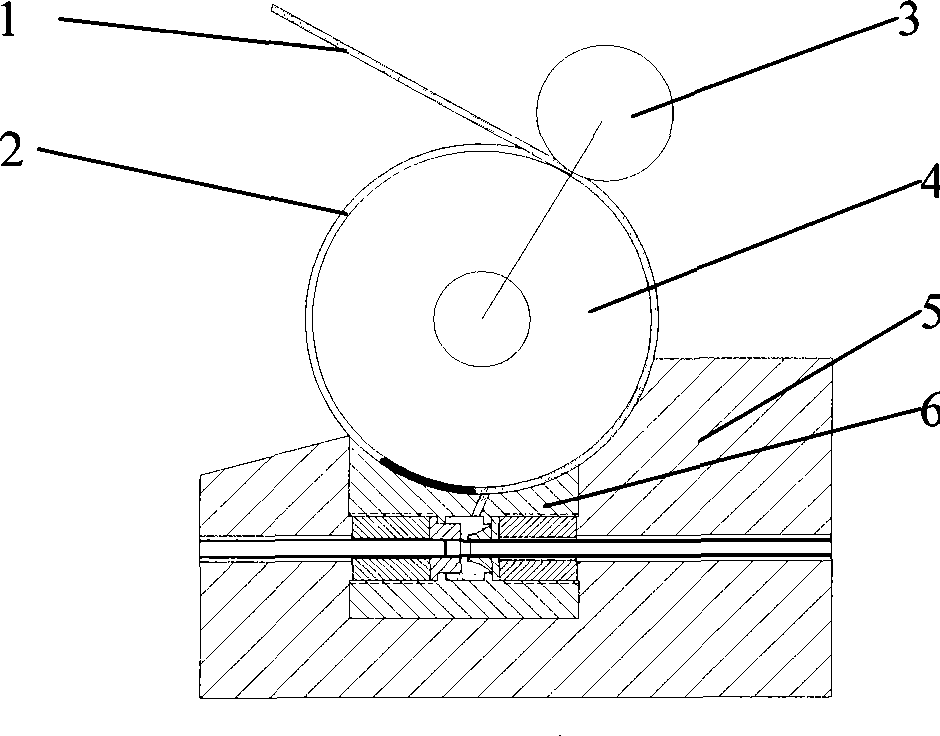

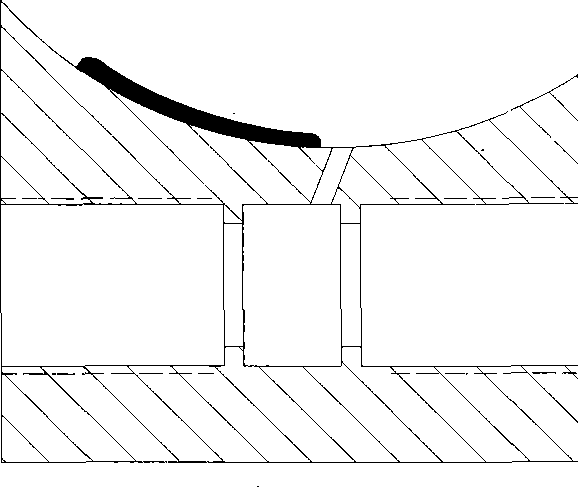

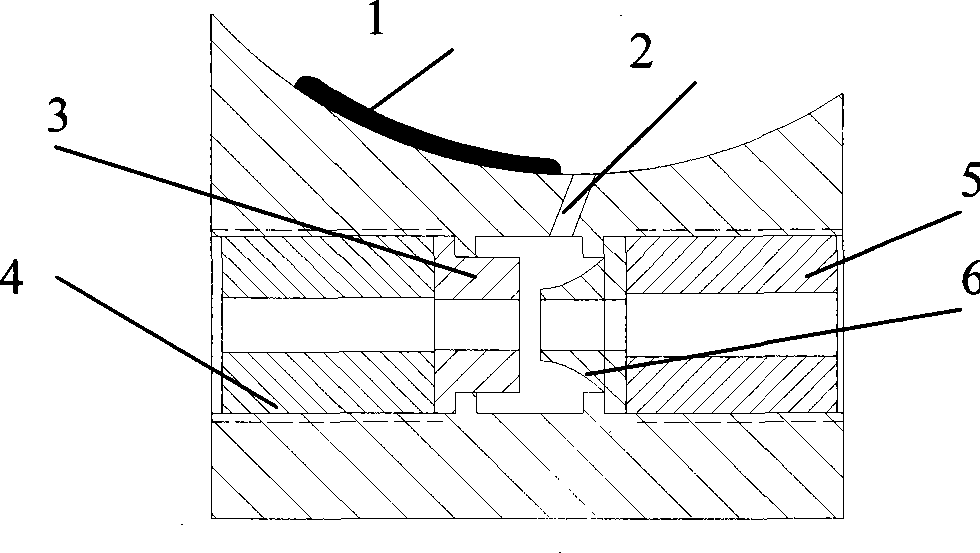

Image

Examples

Embodiment 1

[0047] Example 1: The raw materials are two Φ9.5mm pure aluminum rods and a Φ10mm copper tube with a wall thickness of 1mm (inner diameter 8mm), matching the corresponding moving core head, the inner diameter of the female mold is Φ12mm, and the mold cavity preheating temperature is 500°C, extrusion wheel speed 6rpm.

[0048] Results: A copper-aluminum composite tube with an outer diameter of Φ12mm and an inner diameter of Φ8mm was obtained, with a dimensional accuracy of ±0.05mm, a thickness of aluminum coating of 1mm, no deformation of the copper tube, and good precision of the inner and outer surfaces of the coated tube.

example 2

[0049] Example 2: The raw materials are two Φ9.5mm pure aluminum rods and a Φ10mm copper tube with a wall thickness of 2mm (inner diameter 6mm), matching the corresponding swimming core head, the inner diameter of the female mold is Φ12mm, and the mold cavity preheating temperature is 500 °C, the rotation speed of the extrusion wheel is 10 rpm.

[0050] Results: A copper-aluminum composite pipe with an outer diameter of Φ12mm and an inner diameter of Φ8mm was obtained, with a dimensional accuracy of ±0.08mm, a thickness of clad aluminum of 1mm, a reduced thickness of the copper pipe, a wall thickness of 1mm, and good precision of the inner and outer surfaces of the clad pipe.

example 3

[0051] Example 3: The raw materials are two Φ9.5mm pure aluminum rods and a Φ8mm copper tube with a wall thickness of 1mm (inner diameter Φ6mm), matching the corresponding swimming core head, the inner diameter of the female mold is Φ10mm, and the cavity preheating temperature is 480 °C, the rotation speed of the extrusion wheel is 10 rpm.

[0052] Results: A copper-aluminum composite tube with an outer diameter of Φ10mm and an inner diameter of Φ6mm was obtained, with a dimensional accuracy of ±0.05mm, a thickness of aluminum coating of 1mm, no deformation of the copper tube, and good precision of the inner and outer surfaces of the coated tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com