Extrusion forming mold for cylinder with rib-equipped inner and outer special-shaped surfaces

A technology of extrusion molding and ribbing, applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of difficult processing, high cost, difficult demoulding, etc., and achieve high material utilization and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and examples.

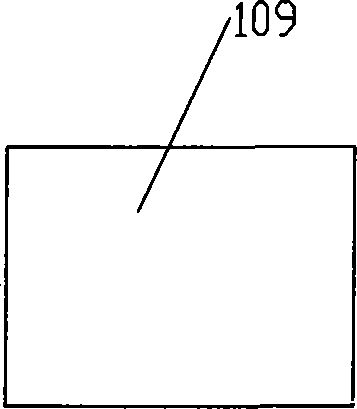

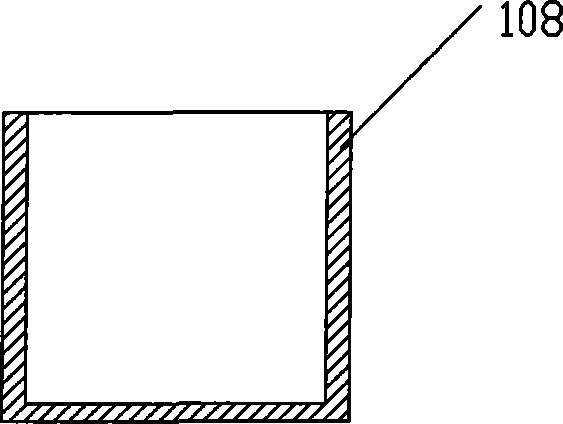

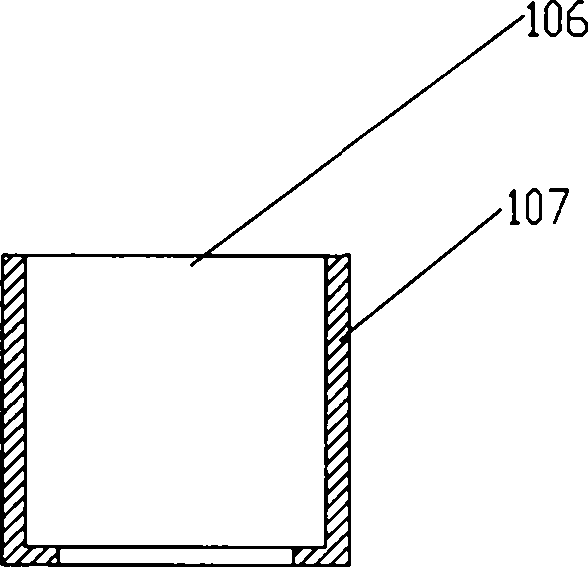

[0026] Such as Figure 5 , Figure 6 , Figure 7 As shown, an extrusion molding die 1 for an inner and outer special-shaped surface ribbed cylinder includes an upper template 2, a mandrel 3, a split die 4, a prestressing ring 5, a split punch mechanism 6, a lower template 7, and an ejector Mechanism 8, ejection mechanism 9.

[0027] Such as Figure 5 , Figure 6 As shown, the lower end of the mandrel 3 is an inverted conical head 31, and the upper end 32 is placed under the upper backing plate 22 and installed under the upper template 2 through the fastening screw 23. The upper backing plate 22 mainly plays the roles of adjustment and buffering.

[0028] Such as Figure 5 , Figure 6 As shown, the prestressing ring 5 is placed on the lower backing plate 71 and installed above the lower formwork 7 through fastening screws 72. The middle part of the prest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com