Axial-radial flow dividing extrusion forming method for thin-walled wide-flange vertical bar tubular member

A technology for extrusion forming and cylindrical parts, which is applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of low overall life, poor mechanical properties, and prone to fatigue cracks, etc., to reduce labor intensity, shorten Manufacturing process, the effect of short manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described.

[0028] The technical scheme that this embodiment mode adopts is: it comprises the following steps:

[0029] 1. Blank blanking;

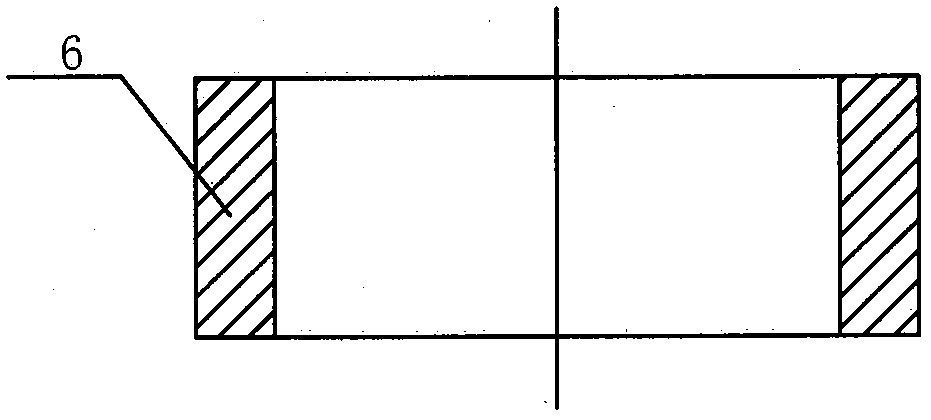

[0030] 2. Homogenizing heat treatment to prepare circular column preform 6, see the structure of preform 6 image 3 shown;

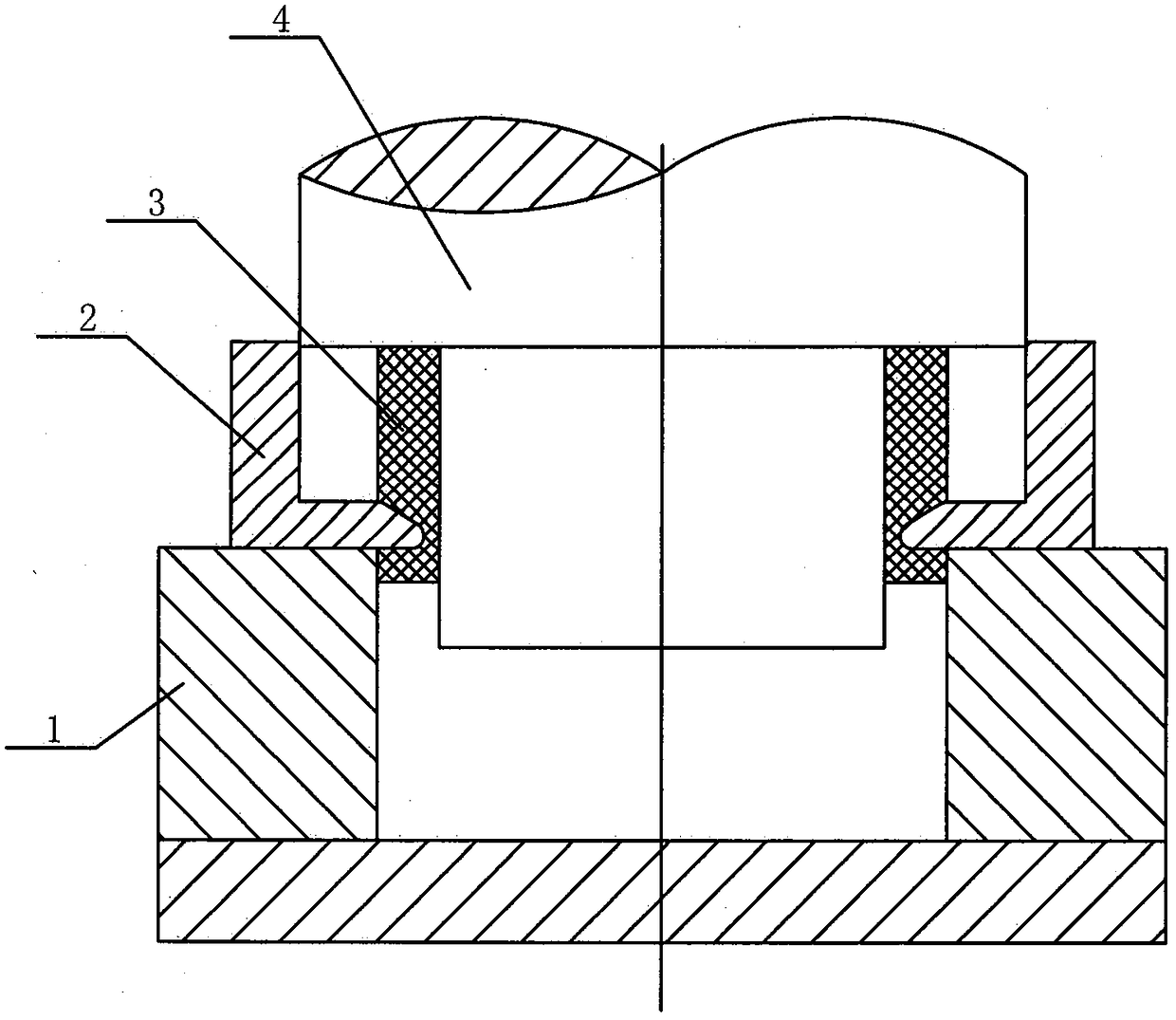

[0031] Three, refer to figure 1 As shown, the hydraulic cylinder (not shown in the figure) installed on the hydraulic cylinder fixing plate 1 pushes the four-lobe split die 2 and simultaneously feeds to the center of the mold, and the preform 6 is partially radially extruded and formed. The bottom flange 3-1 and part of the longitudinal ribs 3-2 are produced to produce a semi-finished product-3; for the structure of the semi-finished product-3, refer to Figure 4-5 shown;

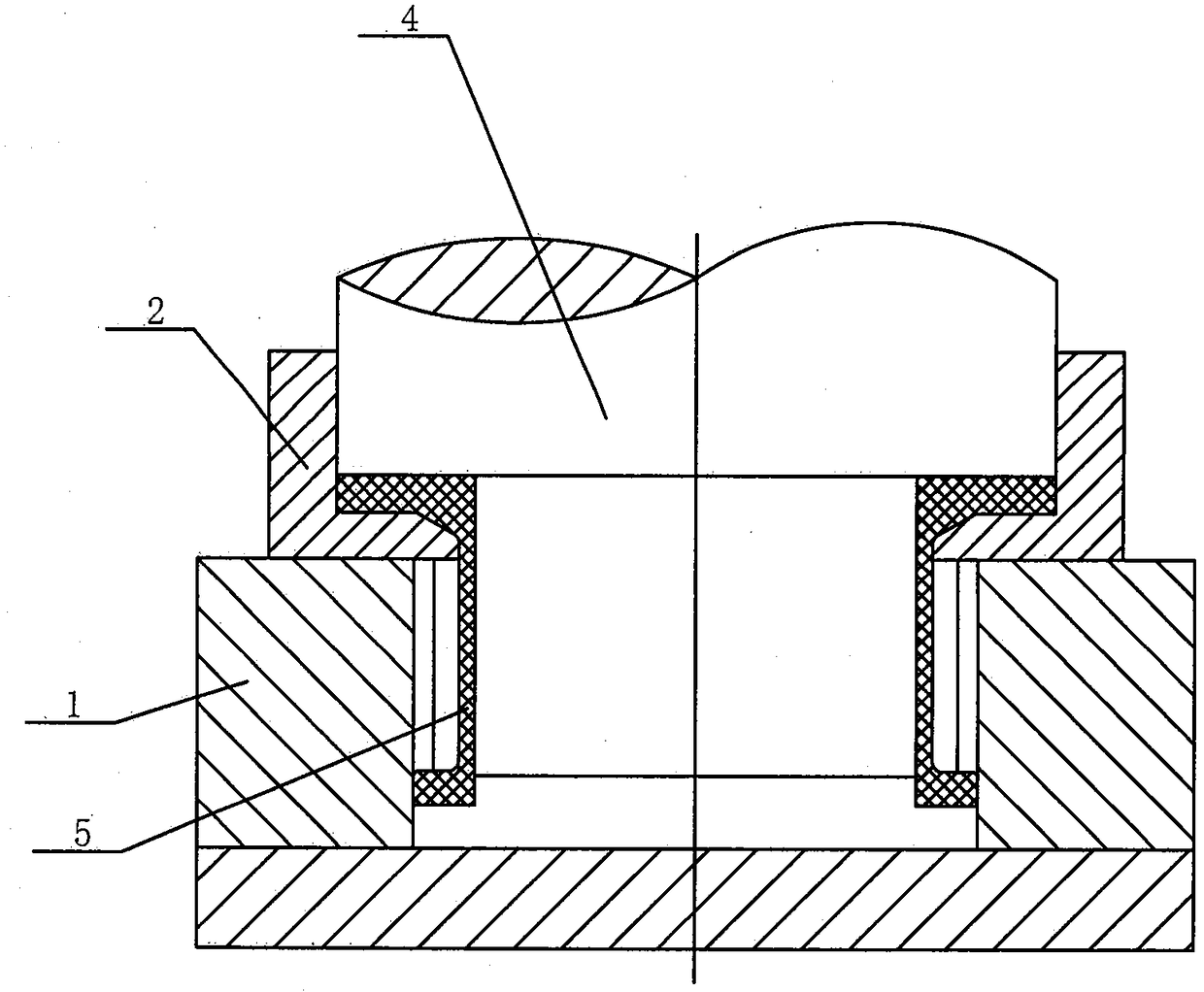

[0032] Four, refer to figure 2 As shown, the hydraulic cylinder controls the split die 2 to keep the feeding position still, and the upper slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com