Equal-channel extrusion mold for forming powder superalloy blank

A technology of equal-channel extrusion and high-temperature alloys, which is applied in metal extrusion dies, metal extrusion mandrels, etc., can solve problems such as harsh experimental conditions, complicated process, and coarse grain size, and achieve comprehensive mechanical properties. Reduced production costs and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This example is an equal-channel extrusion die for powder superalloy billet production, which is used to prepare powder superalloy FGH96 forging billets with a diameter of 300mm and uniform structure of 5-3 grades. The equipment is an isothermal forging hydraulic press with a tonnage of 5000T. . Heat the forging billet to 1070°C in a heating furnace, put it into the mold and make the axis of the forging billet coincide with the centerline of the billet extrusion device.

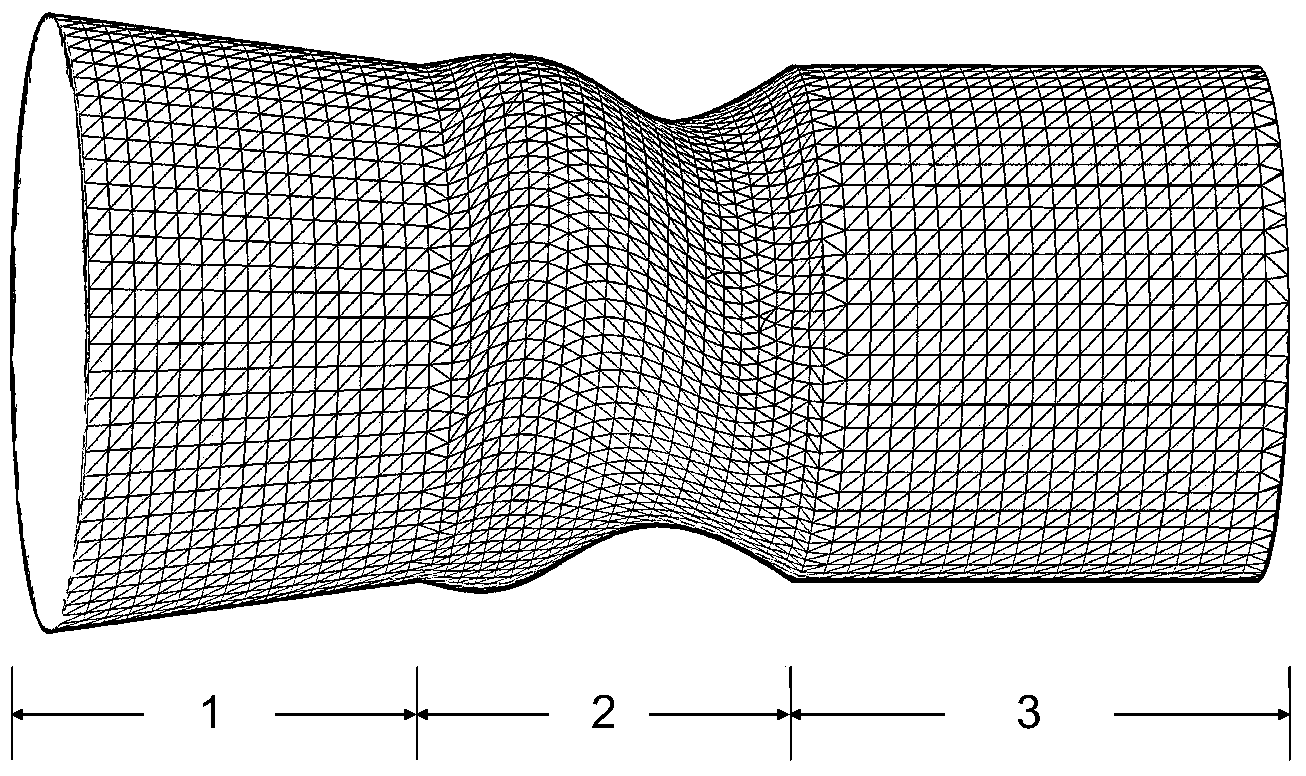

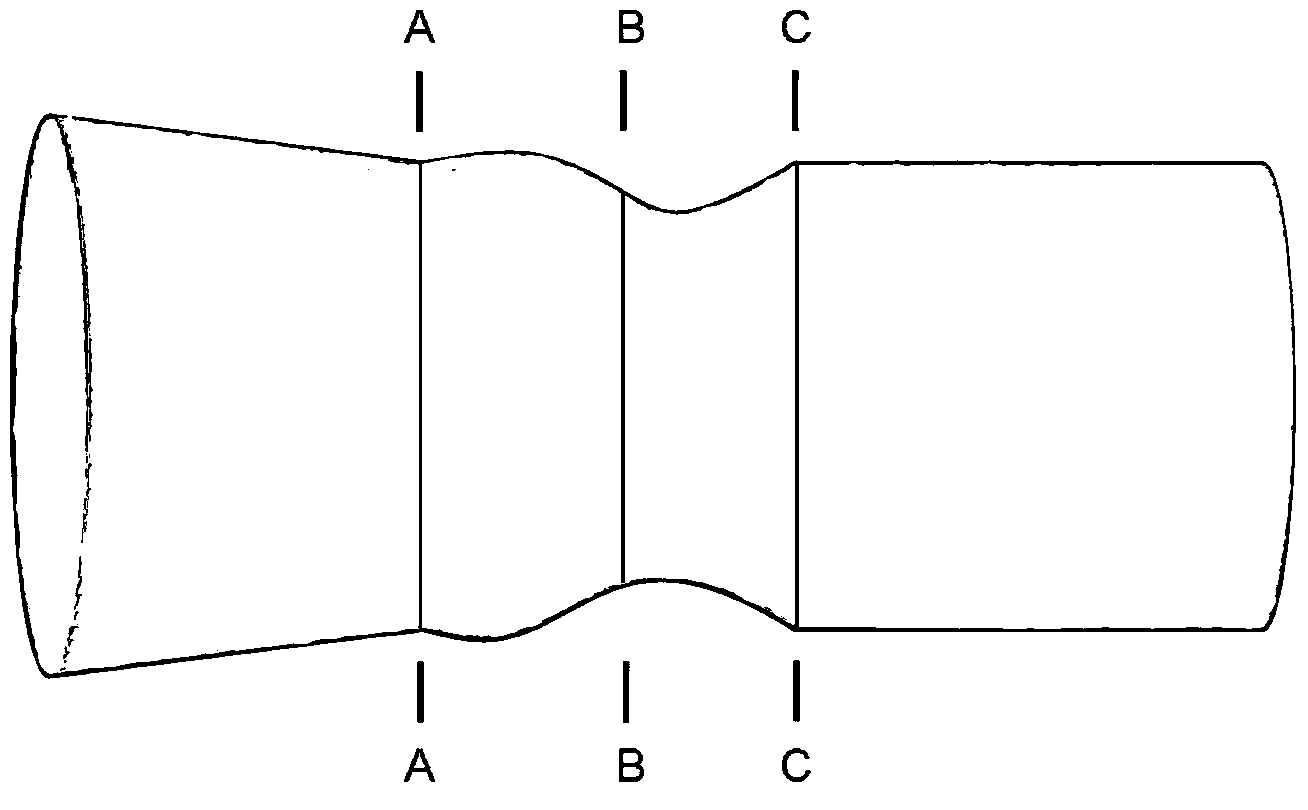

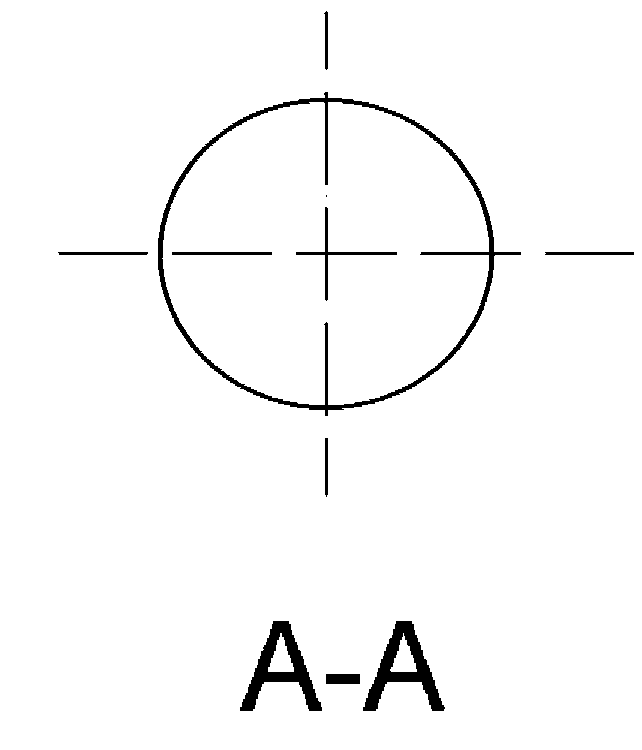

[0021] refer to Figure 1-Figure 5 , the cavity of the equal-channel extrusion die of the present invention is divided into a truncated conical guide section 1, a deformation torsion transition section 2, and a circular shaping section 3; wherein: the cavity of the truncated conical guide section 1 is a variable-diameter circular channel with a smooth inner diameter . In the frustum-shaped guide section 1, the circular diameter of the initial section at the entrance is 360mm, the diameter at the circ...

Embodiment 2

[0023]This embodiment is an equal-channel extrusion die for powder superalloy billet production, which is used to prepare a powder superalloy FGH96 forging billet with a diameter of 600 mm and a grain size of 5 to 3. The equipment is an isothermal forging hydraulic press of 25,000 tons. Heat the forging billet to 1150°C in a heating furnace, put it into the mold and make the axis of the forging billet coincide with the centerline of the billet extrusion device. The cavity of the channel extrusion mold is divided into a frustum-shaped guiding section 1, a deformation and twisting transition section 2, and a circular shaping section 3. Wherein, the cavity of the truncated conical guide section 1 is a variable-diameter circular channel with a smooth inner diameter. In the frustum-shaped guide section 1, the circular diameter of the initial section at the entrance is 720mm, the diameter of the circular termination section A-A is equal to 600mm, and the section in the middle stage ...

Embodiment 3

[0025] This embodiment is used to prepare powdered superalloy FGH95 forging billets with grain diameter of 300mm and uniform structure of grade 5-3. The equipment is an isothermal forging hydraulic press with a tonnage of 6000T. Heat the forging billet to 1100°C in a heating furnace, put it into the mold and make the axis of the forging billet coincide with the centerline of the billet extrusion device. The cavity of the channel extrusion die is divided into a frustum-shaped guiding section 1, a deformation and twisting transition section 2, and a circular shaping section 3. Wherein, the cavity of the truncated conical guide section 1 is a variable-diameter circular channel with a smooth inner diameter. In the frustum-shaped guide section 1, the circular diameter of the initial section at the entrance is 360 mm, the diameter of the circular termination section A-A is equal to 300 mm, and the section in the middle stage transitions smoothly. The length of the cone-shaped guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com