Processing method for producing high-end green tea from Shiqian moss tea variety

A processing method and technology of Shiqian moss, which are applied in the processing field of Shiqian moss tea varieties to make high-grade green tea, can solve the problems of insufficient utilization of tea resources, dark and dull tea soup, simple processing technology, etc., and achieve low moisture content, color and fragrance. Intense, prolonged shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

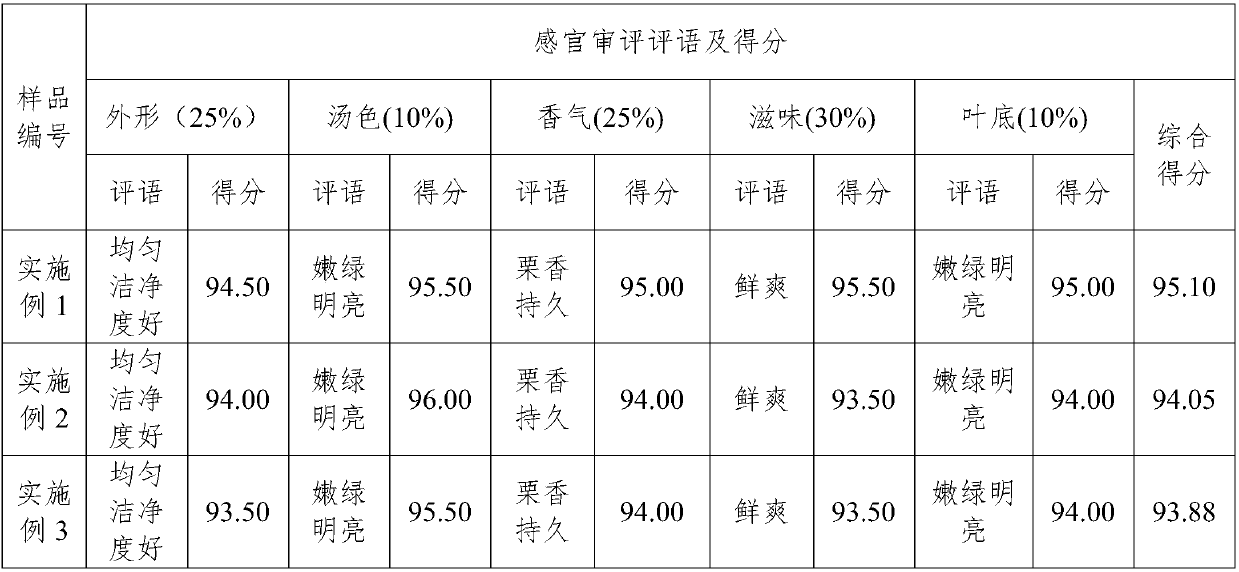

Embodiment 1

[0027] The processing method for making high-grade green tea from Shiqianmoss tea varieties includes the following steps:

[0028] (1) Withering: Before Qingming, the tea greens are picked with one bud and one leaf or one bud and two leaves, uniform in size. Spread the picked tea greens evenly in the withering trough, spreading thickness 3-5cm, spreading time 10h, turn once at 0.5h intervals, and knead once by hand to make the tea green moisture content 60-65%, and the fresh leaves are wilting;

[0029] (2) Crimping: Use a calcining machine to calcinate the withered green tea at a temperature of 150-180°C for 5 minutes. Cool the first calcined tea at room temperature to regain moisture, and then perform a second calcining to calcinate temperature The temperature is 120-150℃, and the time is 3min, until the leaf color turns from green to dark green, the leaf is soft and sticky, and the grass smell disappears. When the tea fragrance is revealed, the curing is over, making the moistur...

Embodiment 2

[0038] The processing method for making high-grade green tea from Shiqianmoss tea varieties includes the following steps:

[0039] (1) Withering: Before Qingming, the tea greens are picked with one bud and one leaf or one bud and two leaves, uniform in size. Spread the picked tea greens evenly in the withering trough, spreading thickness 3-5cm, spreading time 5h, turn once at 1h intervals, and knead once by hand to make the tea green moisture content 70-75%, and the fresh leaves are wilting;

[0040] (2) Curing: Use a curing machine to cure the withered green tea at a temperature of 180-200°C for 3 minutes. Cool the first-cooked tea at room temperature to regain moisture, and then perform a second time to cure the tea. The temperature is 120-150℃, and the time is 2min, until the leaf color turns from green to dark green, the leaf is soft and sticky, and the grass smell disappears. When the tea fragrance is revealed, the curing ends, making the moisture content of the curing leaves ...

Embodiment 3

[0049] The processing method for making high-grade green tea from Shiqianmoss tea varieties includes the following steps:

[0050] (1) Withering: Before Qingming, the tea greens are picked with one bud and one leaf or one bud and two leaves, uniform in size. Spread the picked tea greens evenly in the withering trough, spreading thickness 3-5cm, spreading time 2h, turn once at 0.5h intervals, and knead once by hand to make the tea green moisture content 70-75%, and the fresh leaves are wilting;

[0051] (2) Crimping: Use a calcining machine to calcinate the withered green tea at a temperature of 150-180°C for 5 minutes. Cool the first calcined tea at room temperature to regain moisture, and then perform a second calcining to calcinate temperature The temperature is 120-150℃, and the time is 2min, until the leaf color turns from green to dark green, the leaf is soft and sticky, and the grass smell disappears. When the tea fragrance is revealed, the curing ends, making the moisture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com