Construction method of supporting double-concave occlusal water-stop pile

A construction method and technology of water-stop piles, which are applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as slow construction progress, easy floating, and pile diameter restrictions, and achieve improved pile bearing capacity, clean construction sites, and The effect of strong dam resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

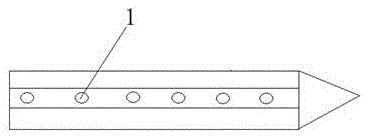

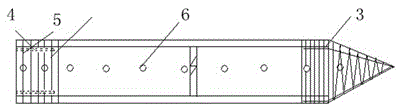

[0049] The prestressed supporting double-concave occluding water-stopping pile includes a pile body and a pile tip. The pile tip is equipped with anchor reinforcement and structural reinforcement. The pile body includes upper pile, middle pile and lower pile. The upper pile has a pile cap and Structural ribs, the lower end of the upper pile is provided with anchor reinforcement; the upper end of the middle pile is provided with threaded anchor holes, the lower end of the middle pile is provided with anchor reinforcement; the upper end of the lower pile is provided with threaded anchor holes, and the lower section of the lower pile is provided with a pile tip; The length of the anchor bar shall be less than the depth of the anchor bar insertion hole 20mm; the two-concave occluding water-stop pile has a double-concave shape on both sides; the double-concave occluding water-stop pile is solid, the section of the pile body is square, and the pile tip is made of steel. Both sides of ...

Embodiment 2

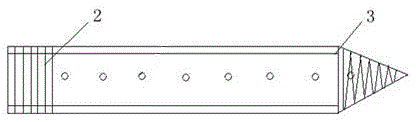

[0061] Non-prestressed supporting double-concave occluding water-stop pile, including pile body and pile tip, the pile tip is equipped with anchor reinforcement and structural reinforcement, the pile body includes upper pile, middle pile and lower pile, and the top of the upper pile is provided with a pile cap The upper end of the upper pile is provided with anchor reinforcement; the upper end of the middle pile is provided with threaded anchor holes, the lower end of the middle pile is provided with anchor reinforcement; the upper end of the lower pile is provided with threaded anchor holes, and the lower section of the lower pile is provided with steel The tip of the pile; the length of the anchor bar shall be less than the depth of the anchor bar insertion hole 25mm; both sides of the double-concave occluding water-stop pile are double-concave; the double-concave occluding water-stop pile is hollow, and the section of the pile body is rectangular. Both sides of the pile body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com