Production process for microorganism control of soy sauce powder

A production process, a technology for soy sauce powder, applied in food science, food ingredients as pH modifiers, food ingredients as taste modifiers, etc., to achieve the effects of low microbial content, reduced microbial content, pleasant and rich flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

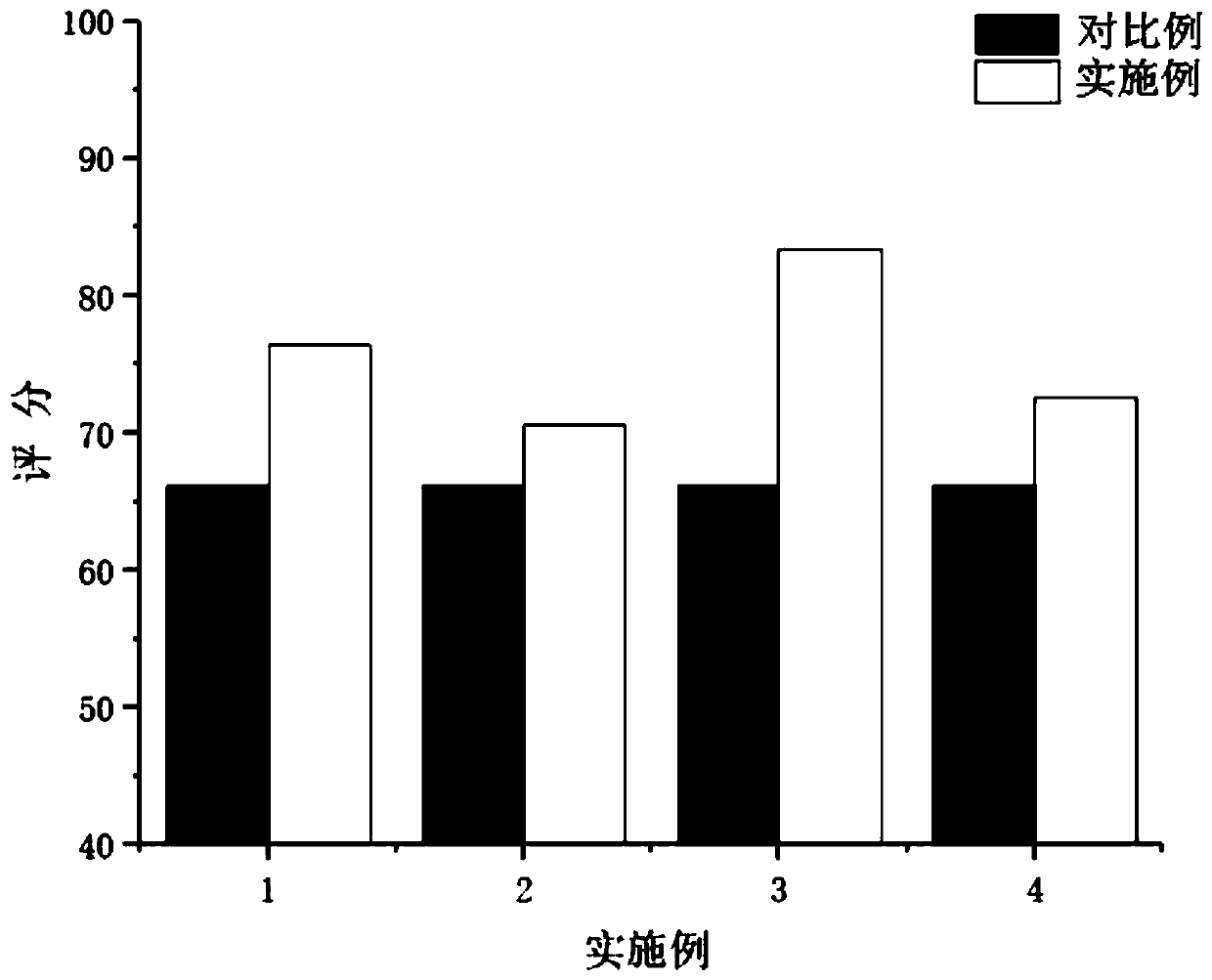

Examples

Embodiment 1

[0025] A kind of production technology of soy sauce powder microbial control:

[0026] Step 1: Add a certain amount of hydrochloric acid to 700 kg of soy sauce stock solution, add 40 kg of oxidized starch and 40 kg of maltodextrin while stirring, adjust the pH to 3.0, and the reaction temperature is 85°C for 0.5 hours;

[0027] Step 2: After the acidification and sterilization, add liquid sodium hydroxide to adjust the pH to 5.0;

[0028] Step 3: Stir and mix the remaining ingredients other than acidification, 600kg of water, 150kg of salt, 10kg of sodium glutamate, and 1kg of disodium succinate, in another reactor according to the formula, and stir and gelatinize at 90°C for 0.5 hours;

[0029] Step 4: Dissolve and stir the reacted and cooled auxiliary materials and acidified soy sauce evenly, filter the feed liquid with a 150-mesh filter, and stay in the ultra-high temperature instantaneous sterilization equipment for 4 seconds at a temperature of 140°C;

[0030] Step 5: Th...

Embodiment 2

[0033] A kind of production technology of soy sauce powder microbial control:

[0034] Step 1: Add a certain amount of hydrochloric acid to 700kg of soy sauce stock solution, adjust the pH to 3.0, react at a temperature of 85°C, and take 0.5 hours;

[0035] Step 2: After the acidification and sterilization, add liquid sodium hydroxide to adjust the pH to 5.0;

[0036] Step 3: Stir and mix the remaining ingredients other than acidification, 600kg of water, 150kg of salt, 10kg of sodium glutamate, and 1kg of disodium succinate, in another reactor according to the formula, and stir and gelatinize at 90°C for 0.5 hours;

[0037] Step 4: Dissolve and stir the reacted and cooled auxiliary materials and acidified soy sauce evenly, filter the feed liquid with a 150-mesh filter, and stay in the ultra-high temperature instantaneous sterilization equipment for 4 seconds at a temperature of 140°C;

[0038] Step 5: The inlet air temperature is 195°C, the outlet temperature is 100°C, and t...

Embodiment 3

[0041] A kind of production technology of soy sauce powder microbial control:

[0042] Step 1: Add a certain amount of hydrochloric acid to 700kg of soy sauce stock solution, add 30kg of oxidized starch and 30kg of white dextrin while stirring, adjust the pH to 4.0, and the reaction temperature is 85°C for 0.5 hours;

[0043] Step 2: After the acidification and sterilization, add liquid sodium hydroxide to adjust the pH to 5.0;

[0044] Step 3: Stir and mix the remaining ingredients other than acidification, 600kg of water, 150kg of salt, 10kg of sodium glutamate, and 1kg of disodium succinate, in another reactor according to the formula, and stir and gelatinize at 90°C for 0.5 hours;

[0045]Step 4: Dissolve and stir the reacted and cooled auxiliary materials and acidified soy sauce evenly, filter the feed liquid with a 200-mesh filter, and stay in the ultra-high temperature instantaneous sterilization equipment for 3 seconds at a temperature of 150°C;

[0046] Step 5: The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com