Preparation method for coated paper coating material and coated paper

A technology for coated paper and coatings, applied in the field of papermaking, can solve the problems affecting the quality of finished coatings and the quality of raw materials, and achieve the effect of avoiding deterioration problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] see figure 1 , figure 1 It is a flow chart of a method for preparing a coated paper coating provided in an embodiment of the present invention, and the method for preparing a coated paper coating in this embodiment includes the following steps:

[0019] S101: Treat the pigment with a long-acting antiseptic fungicide;

[0020] In an embodiment of the present invention, the pigment includes a combination of one or more of precipitated calcium carbonate, ground calcium carbonate and kaolin.

[0021] Typically, the microbial content of untreated pigments reaches 10 5 CFU / ml or even 10 6 Above CFU / ml, the microbial content in the pigment is high, which will have a great negative impact on its quality, such as the viscosity of the pigment paste will increase, the pH will decrease, the growth of anaerobic microorganisms will cause brightness reduction, and hydrogen sulfide odor will be generated. In the embodiment of the present invention, the pigment is treated with a lon...

Embodiment 1

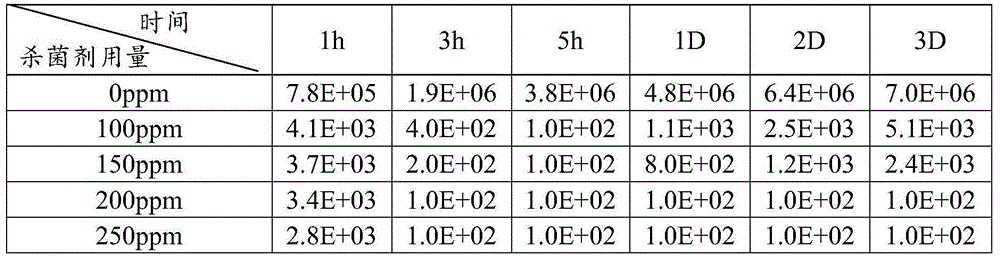

[0041] The number of microorganisms added to the pigments with different amounts of fungicides at different times was detected. In this embodiment, the pigments were ground calcium carbonate, and the fungicides were 5-chloro-2-methyl-4-isothiazolin-3-one and 2 - A 1:1 mixture of methyl-4-isothiazolin-3-one, the amount of fungicide added is relative to the absolute dry weight of the pigment, and the specific test results are shown in Table 1 below:

[0042] Table 1: Microbial content of pigments treated with different amounts of fungicides at different times

[0043]

[0044] It can be seen from the above table that by adding a certain amount of bactericide to treat the pigment, the number of microorganisms in the pigment can be kept in a low range for a long time. Therefore, it can effectively avoid the deterioration caused by too many microorganisms of the pigment raw material (such as pH decrease, viscosity increase, hydrogen sulfide smell, etc.).

Embodiment 2

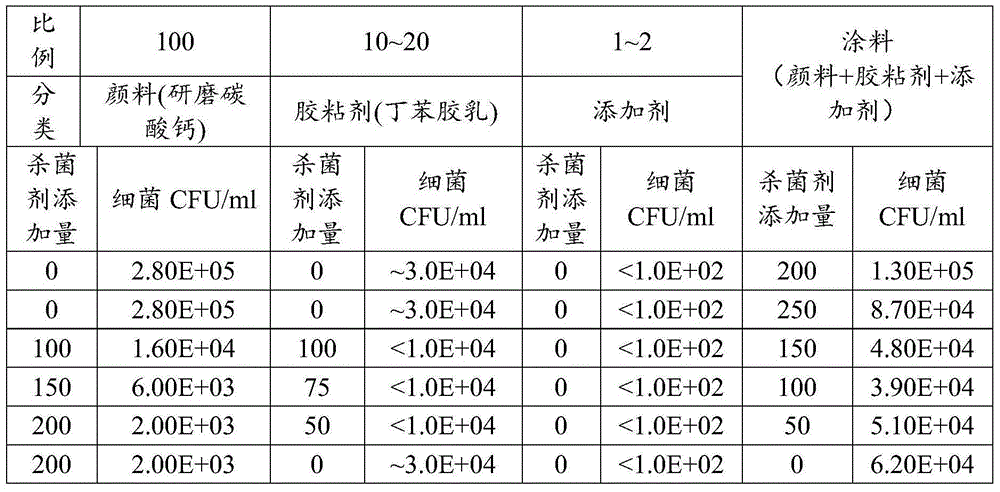

[0046] In this embodiment, the coating formula includes pigment (ground calcium carbonate), adhesive (styrene-butadiene latex) and additives, wherein the additive includes dispersant (sodium polyacrylate), defoamer (tributyl phosphate), lubricant (hard Calcium ester) and water-resistant agent (melamine formaldehyde resin), fungicide using 5 chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one 1:1 mixture, the addition amount of bactericide is the addition amount (unit: ppm) relative to the absolute dry mass of pigment, adhesive and coating, and the coating is prepared by different processing methods of the present invention, and the prepared coating is mixed with The microbial quantity of the coating prepared by the method of the prior art (that is, the method of directly utilizing the bactericide to process the final coating) is tested, and the test results are as follows in Table 2:

[0047]

[0048] From the above test results, it can be known that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com