Production method of instant dried small shrimps

A production method and technology for dried shrimp skin, which are applied in food preparation, food drying, food science and other directions, can solve the problems of high volatile base nitrogen content, single product form of dried shrimp skin, inability to guarantee microorganisms, etc., and achieve less impurity content and better taste. Excellent, the effect of low microbial content in the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

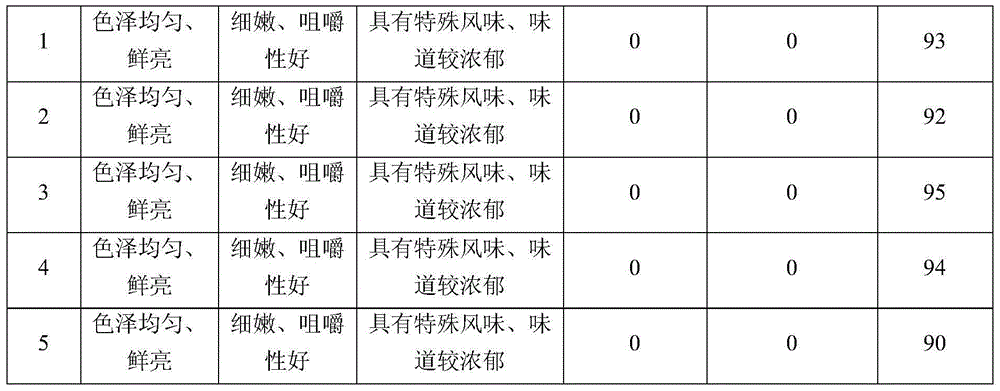

Examples

Embodiment 1

[0026] A preparation method of instant dried shrimp skin includes the following steps:

[0027] Step 1: Clean the shrimp skins: After pre-drying the raw shrimp skins, use a wind sorting machine for wind sorting. The wind power is 5m / s to remove fine impurities and light shrimps. Use a magnet strip to remove the magnetism in the raw shrimp skins. Metal; visually distinguish impurities, remove visible bamboo, wood, stone, glass, nylon, hair, crab, fish, shell impurities, and remove spoiled raw shrimp skin;

[0028] Step 2: Soaking and removing impurities: Put the shrimp skins cleaned in the step 1 into a container with a filter screen with a mesh diameter of 3mm. Put the container into the cleaning bucket, add 2% salt water and soak for 7 minutes, and Stir the shrimp skins, take out the container with a strainer to filter the brine, and thoroughly remove the foreign matter adhering to the shrimp skins;

[0029] Step 3: Centrifugal dehydration: Put the shrimp skins prepared in the seco...

Embodiment 2

[0035] A preparation method of instant dried shrimp skin includes the following steps:

[0036] Step 1: Clean the shrimp skins: After pre-drying the raw shrimp skins, use a wind sorting machine for wind sorting. The wind power is 6m / s to remove fine impurities and light shrimps. Use a magnet strip to remove the magnetism in the raw shrimp skins. Metal; visually distinguish impurities, remove visible bamboo, wood, stone, glass, nylon, hair, crab, fish, shell impurities, and remove spoiled raw shrimp skin;

[0037] Step 2: Soaking and removing impurities: Put the shrimp skins cleaned in the step 1 into a container with a filter screen with a mesh diameter of 3mm. Put the container into the cleaning bucket, add 2% salt water and soak for 7 minutes, and Stir the shrimp skins, take out the container with a strainer to filter the brine, and thoroughly remove the foreign matter adhering to the shrimp skins;

[0038] Step 3: Centrifugal dehydration: Put the shrimp skins prepared in the seco...

Embodiment 3

[0044] A preparation method of instant dried shrimp skin includes the following steps:

[0045] Step 1: Clean the shrimp skins: After pre-drying the raw shrimp skins, use a wind sorting machine for wind sorting. The wind power is 5m / s to remove fine impurities and light shrimps. Use a magnet strip to remove the magnetism in the raw shrimp skins. Metal; visually distinguish impurities, remove visible bamboo, wood, stone, glass, nylon, hair, crab, fish, shell impurities, and remove spoiled raw shrimp skin;

[0046] Step 2: Soaking and removing impurities: Put the shrimp skins cleaned in step 1 into a container with a filter screen with a mesh diameter of 3mm. Put the container into a cleaning bucket, add 3% brine and soak for 12 minutes, and Stir the shrimp skins, take out the container with a strainer to filter the brine, and thoroughly remove the foreign matter adhering to the shrimp skins;

[0047] Step 3: Centrifugal dehydration: Put the shrimp skins prepared in the second step in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com