Method for extracting protein and polypeptide from walnut dregs

A protein polypeptide and walnut protein technology, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of low polypeptide interest rate, low protein extraction rate and protein purity, complex protein polypeptide preparation process, etc. The effect of simplifying the preparation process, enhancing human immunity, and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

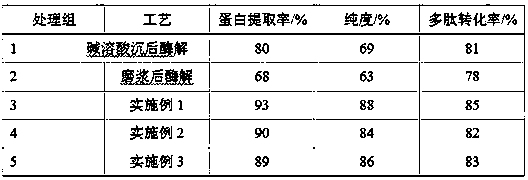

Embodiment 1

[0025] The method for extracting and preparing the walnut protein polypeptide powder of the present embodiment comprises the following steps:

[0026] Step (1), raw material pretreatment: crush the raw material of walnut meal with a pulverizer, and pass through a 60-mesh sieve to obtain crushed walnut meal, and then mix it with water at a weight ratio of 1:5 to obtain a walnut meal mixture, Add non-protein compound enzymes to the mixed solution, the non-protein compound enzymes are composed of cellulase, pectinase and amylase in a ratio of 5:2:3, and the amount of non-protein compound enzymes added is 0.1% of the quality of the walnut crushed material, The reaction temperature is 35°C, the reaction time is 3 hours, the whole process is stirred, and the stirring speed is 30r / min, and a suspension of walnut meal broken wall is obtained;

[0027] Step (2), alkali dissolution and enzymatic hydrolysis: add the above suspension to the reaction tank, and add Ca(OH) to the above suspe...

Embodiment 2

[0032] The preparation method for extracting walnut polypeptide powder of the present embodiment comprises the following steps:

[0033] Step (2), raw material pretreatment: crush the raw material of walnut meal with a pulverizer, and pass through a 60-mesh sieve to obtain crushed walnut meal, and then mix it with water at a weight ratio of 1:6 to obtain a walnut meal mixture, Add non-protein complex enzymes to the mixed solution, the non-protein complex enzymes are composed of cellulase, pectinase and amylase in a ratio of 4.5:2:3.5, and the amount of non-protein complex enzymes added is 0.2% of the walnut crushed material quality, The reaction temperature is 37°C, the reaction time is 4 hours, the whole process is stirred, and the stirring speed is 30r / min, and a suspension of walnut meal broken wall is obtained;

[0034]Step (2), alkali dissolution and enzymatic hydrolysis: add the above suspension to the reaction tank, add NaOH solution to the above suspension, adjust the ...

Embodiment 3

[0039] The preparation method for extracting walnut polypeptide powder of the present embodiment comprises the following steps:

[0040] Step (1), raw material pretreatment: crush the walnut meal raw material with a pulverizer, and pass through a 60-mesh sieve to obtain the walnut meal crushed material, and then mix it with water at a weight ratio of 1:7 to obtain a walnut meal mixture solution, add non-protein compound enzymes to the mixed liquid, the non-protein compound enzymes are composed of cellulase, pectinase and amylase in a ratio of 5:1.5:3.5, and the amount of non-protein compound enzymes added is 0.3% of the mass of walnut crushed material %, the enzymatic hydrolysis temperature is 40°C, the enzymatic hydrolysis time is 5h, and the whole process is stirred at a stirring speed of 30r / min to obtain a suspension of broken walnut meal;

[0041] Step (2), alkali dissolution and enzymatic hydrolysis: add the above suspension to the reaction tank, add NaOH solution to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com