The preparation method of total paeoniflorin

A technology of total paeoniflorin and white peony, which is applied in the field of preparation of total paeoniflorin, which can solve the problems of difficult regeneration of resin, low adsorption capacity of total paeoniflorin, and high cost of extract, and achieve short operation time, clear extract and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

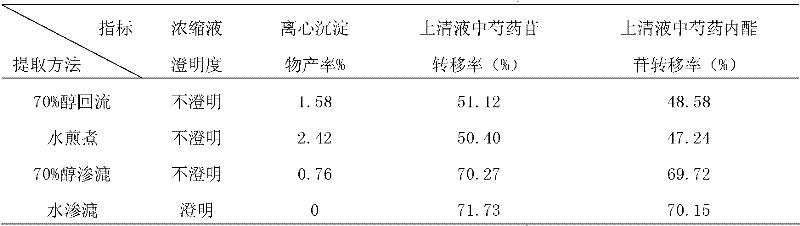

Method used

Image

Examples

Embodiment 1

[0039] Take 750g of Radix Paeoniae Alba produced in Zhongjiang, Sichuan, add 4 times the amount of medicinal material in the percolator, add the medicinal material of Radix Paeoniae Alba, soak for 2 hours and percolate, the flow rate is 1 times the amount of medicinal materials per hour, and collect 7 times the amount of medicinal materials for percolation. solution, concentrated under reduced pressure to a relative density of 1.05 to 1.07 (measured at 60°C), filtered to obtain an extract for later use. Take 500 g of ME-1 macroporous adsorption resin and pack it into a column. Take the above extract, pass it through the macroporous adsorption resin column, the flow rate is 2 times the amount of resin per hour, and discard the effluent. Rinse the resin column with 10% methanol solvent 3 times the amount of resin, flow rate is 3 times the amount of resin / hour, and discard the effluent. Rinse the resin column with 4 times the amount of resin and 40% methanol solvent, the flow ra...

Embodiment 2

[0043] Take 750g of Radix Paeoniae Alba produced in Bozhou, Anhui Province, add 4 times the amount of water in the percolator, add Radix Paeoniae Alba, soak for 2 hours, and percolate at a flow rate of 2 times the amount of medicinal materials per hour, and collect 10 times the amount of medicinal materials for percolation. solution, concentrated under reduced pressure to a relative density of 1.09 (measured at 60°C), filtered to obtain an extract for later use. Take 500 g of D-101 macroporous adsorption resin and pack it into a column. Take the above extract, pass it through a macroporous adsorption resin column at a flow rate of 3 times the amount of resin per hour, and discard the effluent. Rinse the resin column with water 3 times the resin volume at a flow rate of 3 times the resin volume / hour, and discard the effluent. Rinse the resin column with 3 times the amount of resin and 50% ethanol solvent, the flow rate is 3 times the amount of resin per hour, collect the 50% m...

Embodiment 3

[0046] Take 480g of Radix Paeoniae Rubra from Inner Mongolia, add 5 times the amount of medicinal material to the percolator, add the Radix Paeoniae Rubra Radix, soak for 1 hour, and percolate at a flow rate of 2.5 times the amount of medicinal materials per hour, and collect 12 times the amount of medicinal materials. , concentrated under reduced pressure to a relative density of 1.06 (measured at 60°C), filtered to obtain an extract for later use. Take 500 g of D-101 macroporous adsorption resin and pack it into a column. Take the above extract, pass it through a macroporous adsorption resin column at a flow rate of 1 times the amount of resin per hour, and discard the effluent. Rinse the resin column with 10% ethanol solution 4 times the amount of resin, flow rate is 2 times the amount of resin / hour, and discard the effluent. Rinse the resin column with 6 times the amount of resin and 35% ethanol solvent, flow rate is 2 times the amount of resin per hour, collect 35% ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com