Peeling method of two-dimensional layered nano material

A two-dimensional layered nano-octadecyl dimethyl ammonium chloride technology, which is applied in nanotechnology, chemical instruments and methods, lamination, etc., can solve the problem of high operating environment requirements for chemical reagents and lack of industrial production , chemical stripping method time-consuming and other problems, to achieve the effect of low cost, high yield and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

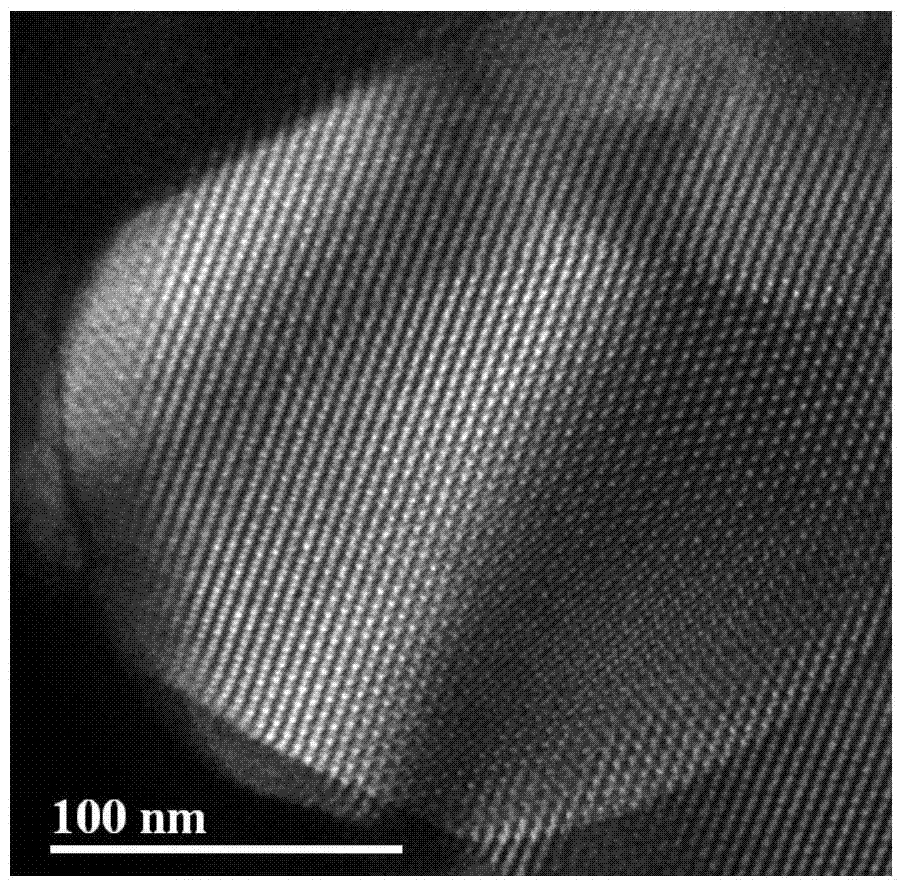

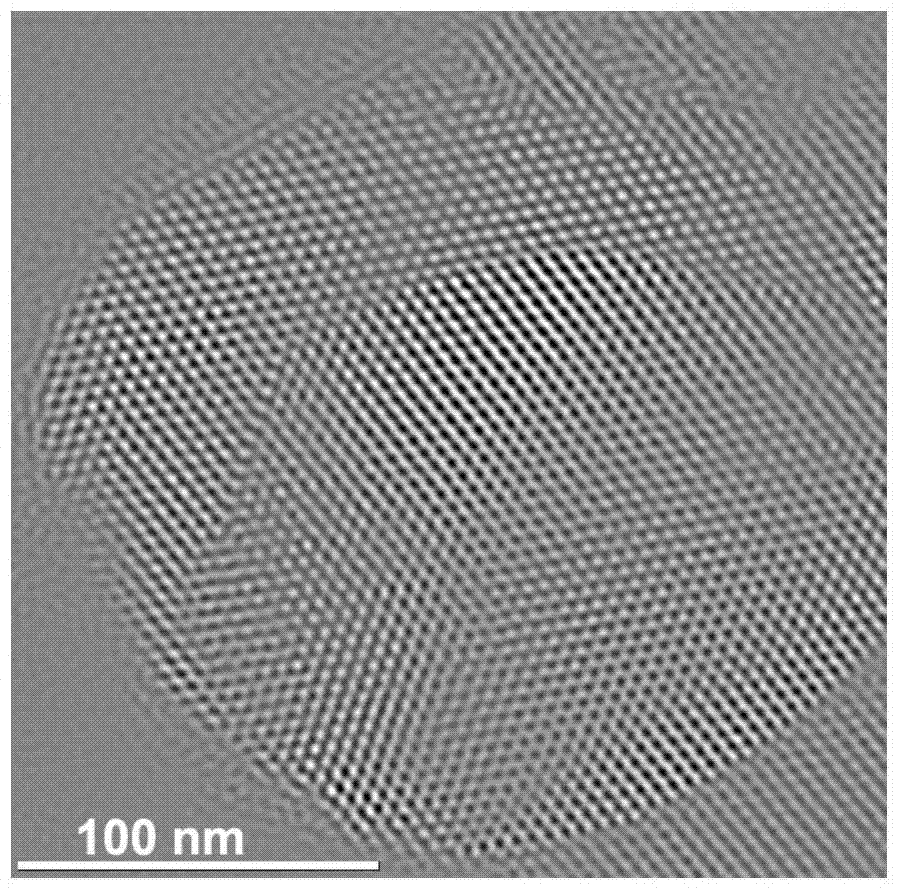

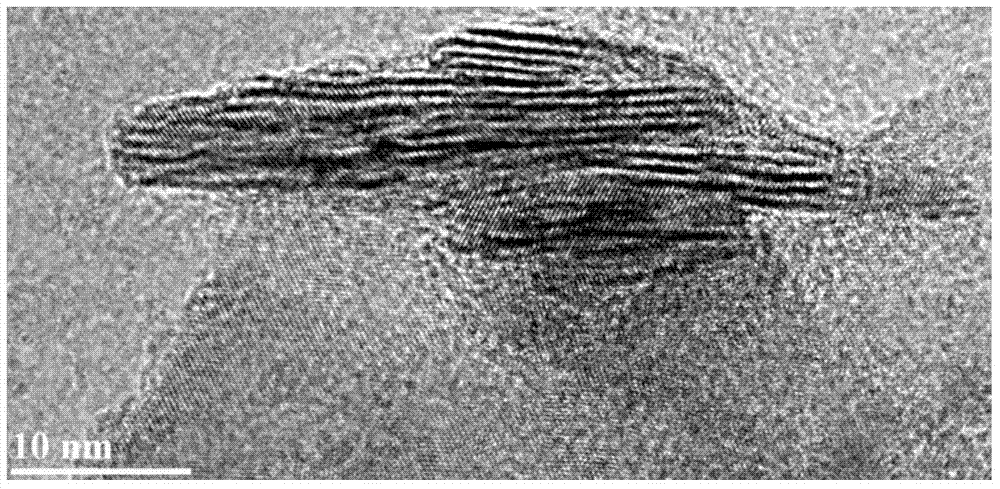

Image

Examples

Embodiment 1

[0041] A molybdenum disulfide (MoS 2 ) stripping method, comprises the steps:

[0042] (1) Graphite pretreatment: Add 100mg of graphite powder (Sigma Aldrich, 1μm) into 10mL of 80°C sulfuric acid solution, keep magnetic stirring for 4 hours and stop heating, slowly add 2L of deionized water to the mixed solution for dilution, and let it stand for 8 hours , and then filtered (using PTFE filter membrane, diameter 47mm, Millipore filter) to remove the sulfuric acid solution, the filtered solid was vacuum dried at 100°C for subsequent use;

[0043] Preparation of graphene oxide: Add the above-mentioned pretreated graphite powder (5g) into a mixed solution of nitric acid (33mL, 68%) and sulfuric acid (200mL, 98%), and after magnetically stirring in an ice bath for 30 minutes, 30g high Potassium manganate (KMnO 4 ) into the above mixture slowly and keep the temperature at about 5°C. After the potassium permanganate is completely added, the reaction temperature is raised to 40°C, s...

Embodiment 2

[0049] A kind of tungsten disulfide (WS 2 ) stripping method, comprises the steps:

[0050] (1) Graphite pretreatment: Add 100mg of graphite powder (Sigma Aldrich, 1μm) into 10mL of 80°C sulfuric acid solution, keep magnetic stirring for 4 hours and stop heating, slowly add 2L of deionized water to the mixed solution for dilution, and let it stand for 8 hours , and then filtered (using PTFE filter membrane, diameter 47mm, Millipore filter) to remove the sulfuric acid solution, the filtered solid was vacuum dried at 100°C for subsequent use;

[0051] Preparation of graphene oxide: Add the above-mentioned pretreated graphite powder (5g) into a mixed solution of nitric acid (33mL, 68%) and sulfuric acid (200mL, 98%), and after magnetically stirring in an ice bath for 30 minutes, 30g high Potassium manganate (KMnO 4 ) into the above mixture slowly and keep the temperature at about 5°C. After the potassium permanganate is completely added, the reaction temperature is raised to 40...

Embodiment 3

[0057] A kind of tungsten disulfide (WS 2 ) stripping method, comprises the steps:

[0058] Add 2g of octadecyldimethylammonium chloride (Sigma Aldrich) into 500mL of isopropanol (IPA), place it in a water bath ultrasonicator (Branson2510EMT) and sonicate at 750w for 2h to obtain a mixed solution, then weigh 2g of disulfide Tungsten (WS 2 ) powder (Sigma Aldrich, 1 μm) was added to the above mixed solution, and then placed in a probe-type intense dispersion ultrasonic instrument (Vibra-Cell TM VCX), 1500W ultrasound for 2h;

[0059] After the ultrasonication is completed, centrifuge the above mixed solution at 1500rpm for 60 minutes, remove the supernatant, and repeatedly wash the centrifuged precipitate with deionized water (three to four times) to completely remove octadecyl dimethyl chloride ammonium, and finally collect the precipitated product and filter it (PTFE filter membrane, diameter 47mm, Millipore filter), and then vacuum dry (100°C) to obtain tungsten disulfide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com