Cement grinding aid and preparation method thereof

A technology of cement grinding aid and weight percentage, which is applied in the field of cement additives, can solve the problem that the improvement of cement performance is not very obvious, and achieve the effect of good effect, special process and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

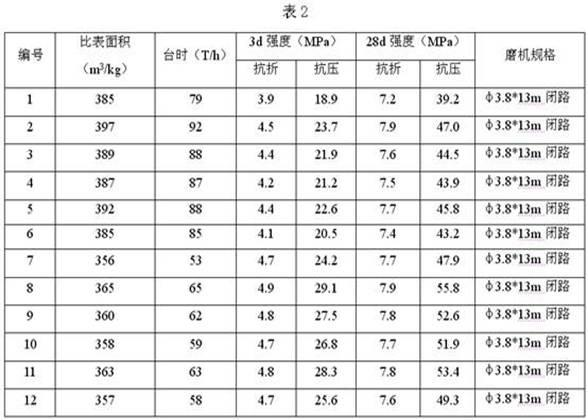

Examples

Embodiment 1

[0024] Prepare cement grinding aid A with the following components: 10% triethanolamine, 3% triisopropanolamine, 10% glycol by-product, 2% synthetic glycerin, molasses 20%, wood calcium 3%, polyurethane 12% ester, 5% cystine, 3% sorbitol, 8% sodium carboxymethyl cellulose, 0% citric acid, 2% silica fume, 0% fly ash, and the rest is water. The glycol by-products include ethylene glycol with a mass content of 30-40% and diethylene glycol with a mass content of 30-60%. The preparation method is as follows: add wood calcium into water, stir to dissolve fully, and then filter the filtrate with a 150-mesh sieve, pulverize the polyurethane to 30-50 mesh with a pulverizer, and then grind the pulverized polyurethane , cystine carboxyl, sodium methylcellulose, silicon powder and citric acid were added to the above filtrate, and treated with ultrasonic waves (ultrasonic power 20-30kw, time 1-2h), after ultrasonic treatment, the remaining ingredients were added to the filtrate, After sti...

Embodiment 2

[0026] Prepare cement grinding aid B with the following components: 8% triethanolamine, 10% triisopropanolamine, 8% glycol by-product, 5% synthetic glycerin, molasses 10%, wood calcium 0%, polyurethane 10% ester, 0% cystine, 3% sorbitol, 5% sodium carboxymethyl cellulose, 1% citric acid, 5% silica fume, 2% fly ash, and the rest is water. Its preparation method is with embodiment 1.

Embodiment 3

[0028] Prepare cement grinding aid C with the following components: 20% triethanolamine, 0% triisopropanolamine, 10% glycol by-product, 0% synthetic glycerin, molasses 5%, wood calcium 5%, polyurethane 0% ester, 8% cystine, 5% sorbitol, 10% sodium carboxymethylcellulose, 5% citric acid, 0% silica fume, 3% fly ash, and the rest is water. Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com