Organic boron-zirconium cross-linking agent and preparation method thereof

A cross-linking agent, boron-zirconium technology, applied in the field of oil field fracturing fluid, can solve the problems of harsh preparation conditions, complicated operation process, expensive raw materials, etc., achieve mild reaction conditions, great market prospects, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of organic boron zirconium crosslinking agent, its formula is:

[0033] Calculated in parts by weight:

[0034] 1 part of zirconium oxychloride; 2 parts of water; 3 parts of isopropanol; 0.4 part of boric acid; 4 parts of methanol; 2 parts of glycerol; 1 part of sodium lactate; 1 part of triethanolamine;

[0035] This organic boron zirconium crosslinking agent is prepared by the following steps:

[0036] (1) Mix 10g of zirconium oxychloride with 20g of water and 30g of isopropanol to form a zirconium salt solution, add it to a flask, and feed ammonia gas into the solution at 55°C, and reflux for 0.5 hours;

[0037] (2) Add 20g of glycerol, 10g of sodium lactate, 10g of triethanolamine, and 5g of tetrahydroxypropylethylenediamine to the flask in sequence, and react for 3 hours;

[0038] (3) Add a boron solution composed of 4g of boric acid and 40g of methanol into the flask, and react for 3 hours to obtain a light yellow organic boron-zirconium crosslinking agen...

Embodiment 2

[0040] A kind of organic boron zirconium crosslinking agent, its formula is:

[0041] Calculated in parts by weight:

[0042] 1 part of zirconium oxychloride; 4 parts of water; 6 parts of isopropanol; 0.5 part of borax; 10 parts of methanol; 4 parts of ethylene glycol; 2 parts of sodium lactate; 2 parts of triethanolamine;

[0043] This organic boron zirconium crosslinking agent is prepared by the following steps:

[0044] (1) Mix 10g of zirconium oxychloride, 40g of water and 60g of isopropanol to form a zirconium salt solution, add it to a flask, and feed ammonia gas into the solution at 60°C, and reflux for 1 hour;

[0045] (2) Add 40g of ethylene glycol, 20g of sodium lactate, 20g of triethanolamine, and 5g of tetrahydroxypropylethylenediamine to the flask in sequence, and react for 2 hours;

[0046] (3) Add a boron solution composed of 5 g of borax and 100 g of methanol to the flask, and react for 2 hours to obtain a light yellow organic boron-zirconium crosslinking age...

Embodiment 3

[0048] A kind of organic boron zirconium crosslinking agent, its formula is:

[0049] Calculated in parts by weight:

[0050] 1 part of zirconium tetrachloride; 2 parts of water; 4 parts of isopropanol; 0.8 parts of boric acid; 8 parts of methanol; 4 parts of glycerol; 1 part of sodium gluconate; 1 part of triethanolamine; share.

[0051] This organic boron zirconium crosslinking agent is prepared by the following steps:

[0052] (1) Mix 10g of zirconium tetrachloride, 20g of water and 40g of isopropanol to form a zirconium salt solution, add it to a flask, and feed ammonia gas into the solution at 58°C, and reflux for 1 hour;

[0053] (2) Add 40g of glycerol, 10g of sodium gluconate, 10g of triethanolamine, and 10g of tetrahydroxypropylethylenediamine to the flask in sequence, and react for 3 hours;

[0054] (3) Add a boron solution composed of 8g boric acid and 80g methanol to the flask, and react for 2 hours to obtain a light yellow organic boron-zirconium crosslinking a...

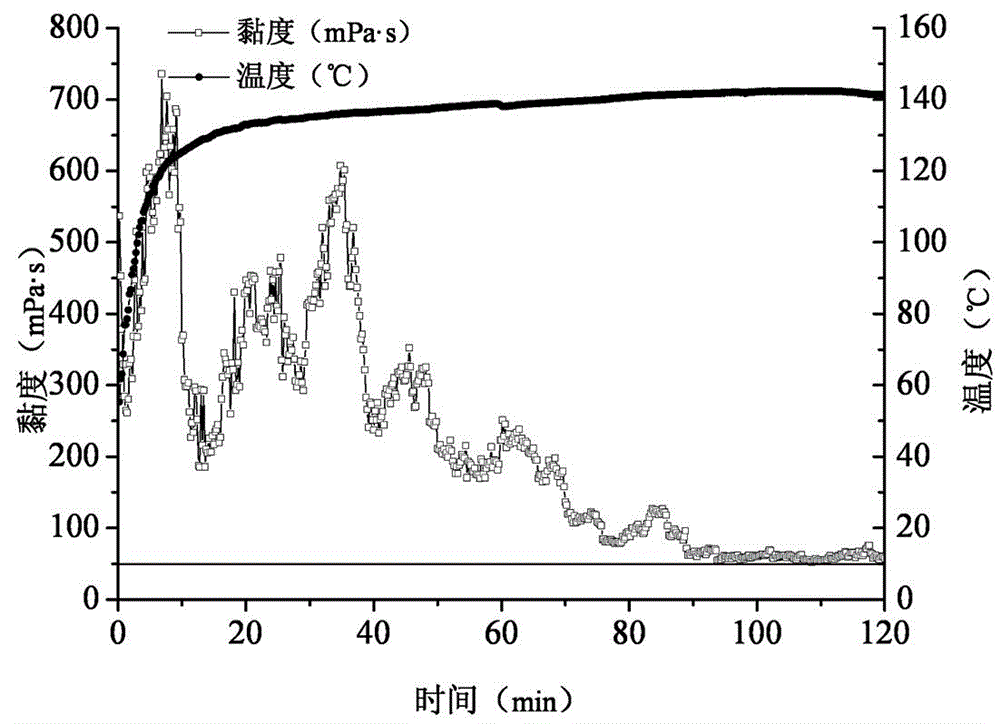

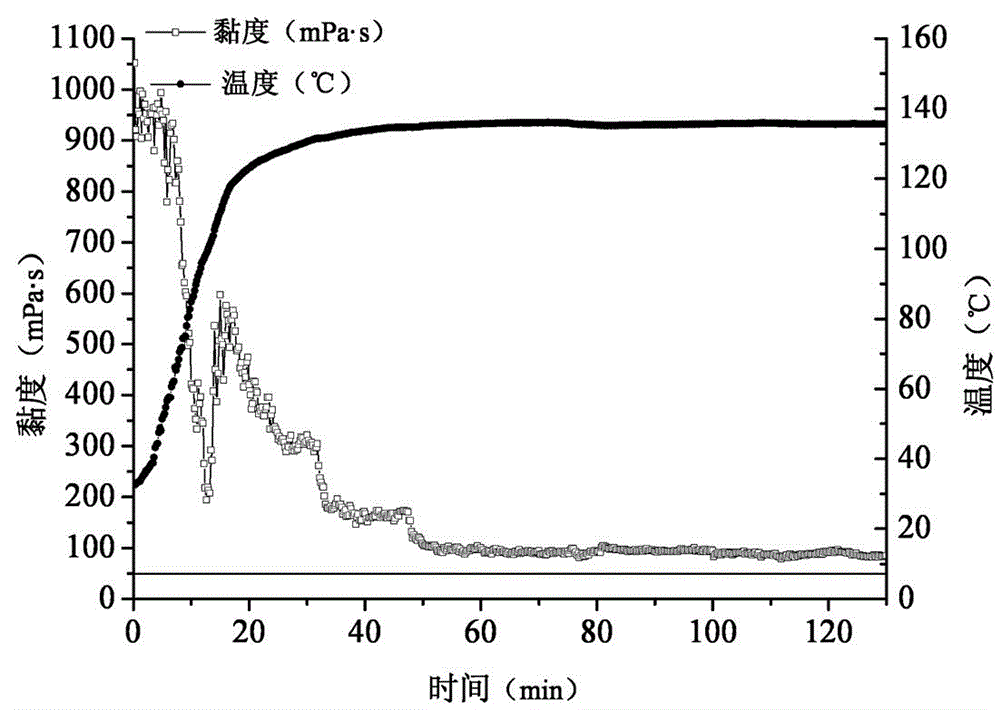

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com