Dye-sensitized solar cell and preparation method of ZnO composite photo-anode of dye-sensitized solar cell

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of long reaction time, low photoelectric conversion efficiency, slow electron transmission of ZnO nanocomposite structure photoanode, etc., achieve short reaction time, improve photoelectric conversion efficiency, The effect of increasing the electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] An embodiment of the present invention provides a method for preparing a ZnO composite photoanode for a dye-sensitized solar cell, comprising the following steps:

[0021] S01. depositing a ZnO nanoparticle layer on a conductive substrate;

[0022] S02. With the ZnO nanoparticle layer prepared above facing down, the conductive substrate carrying the ZnO nanoparticle layer is horizontally suspended in Zn salt solution and reacted at a temperature of 80°C to 95°C, so that the ZnO nanoparticle layer surface grows ZnO nanowire array;

[0023] S03. With the above-mentioned ZnO nanowire array facing down, suspend the conductive substrate loaded with the ZnO nanowire array horizontally in the polyol solution of Zn salt and react at a temperature of 130°C to 220°C until the solution is milky white and the reaction is completed , and then wash and dry the product to obtain a ZnO composite photoanode for a dye-sensitized solar cell.

[0024] In all the steps of the embodiment o...

Embodiment 1

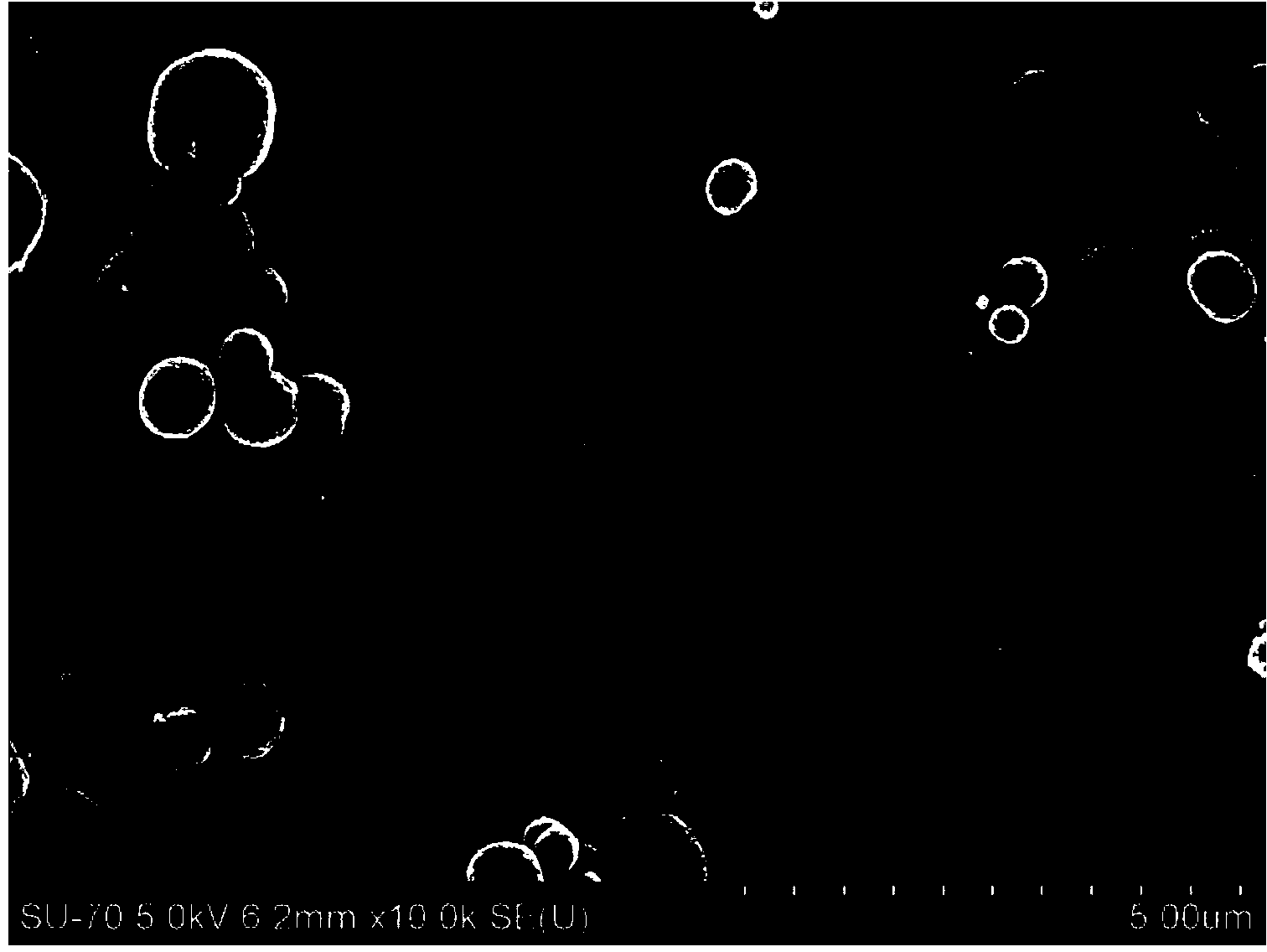

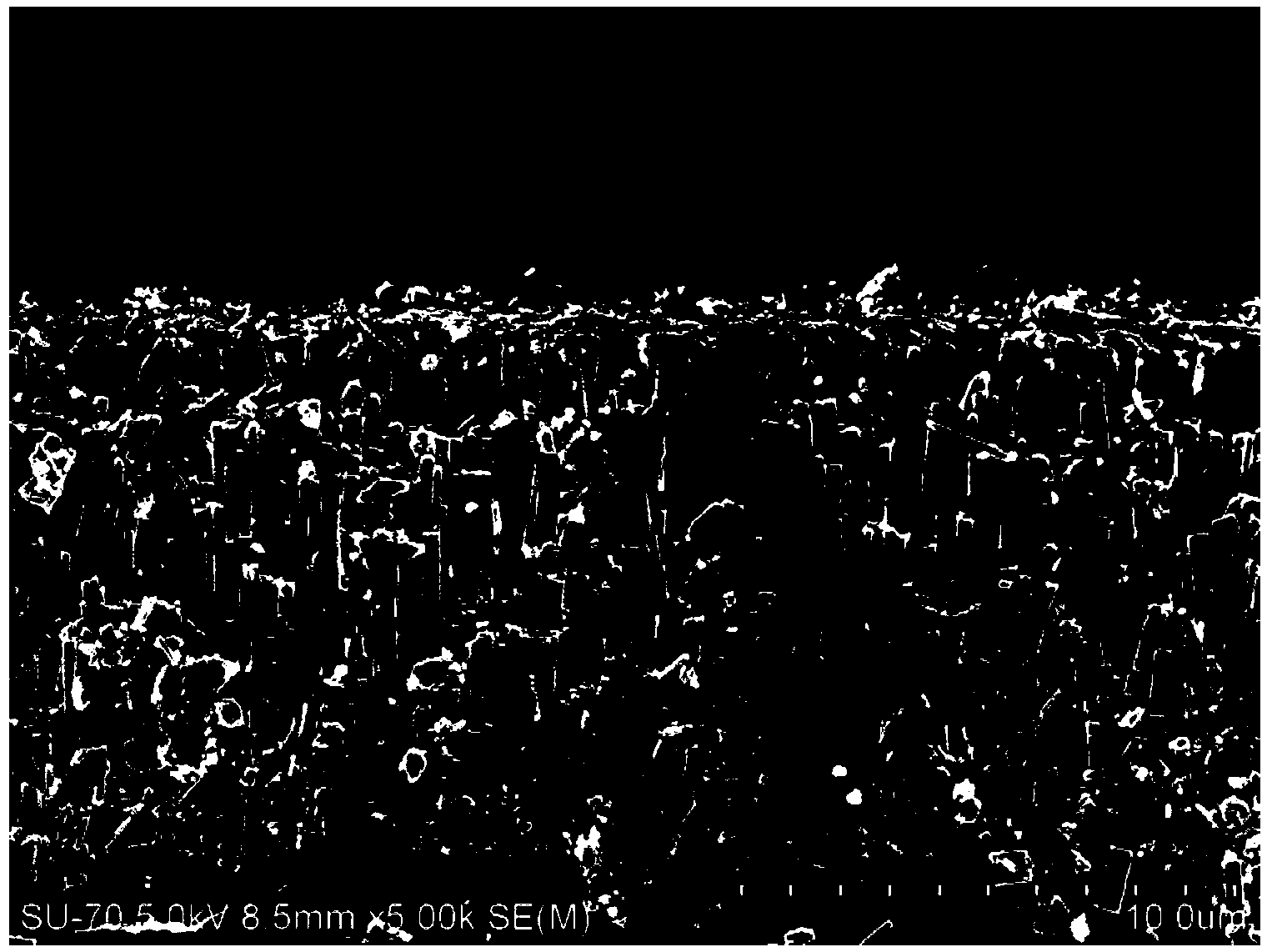

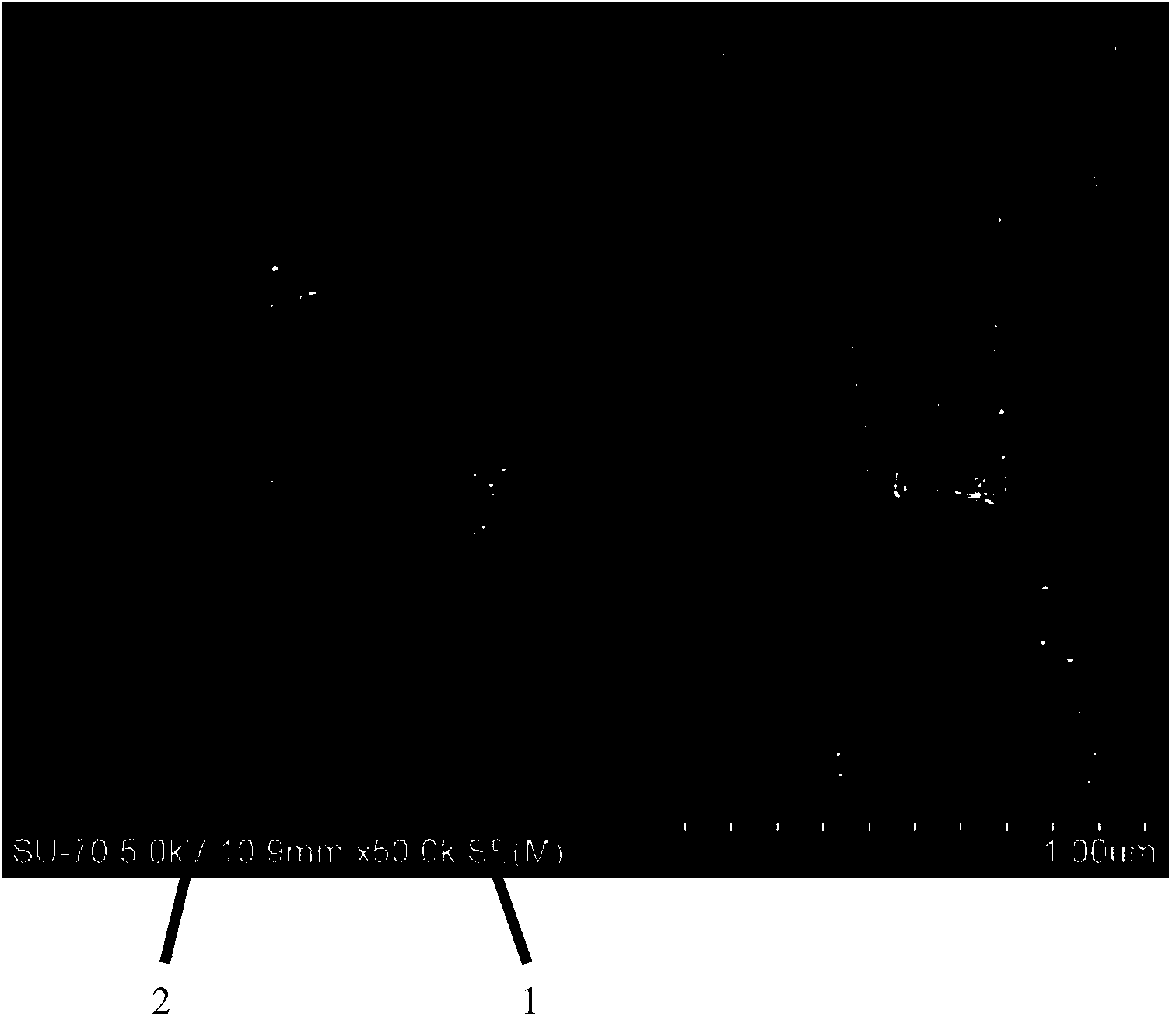

[0045] Figure 1~3 A scanning electron microscope image of the ZnO composite photoanode of the dye-sensitized solar cell prepared in Example 1 is provided, wherein, 1 represents a nanowire, and 2 represents a nanoparticle. Correspondingly, the method for preparing the ZnO composite photoanode of the dye-sensitized solar cell comprises the following steps:

[0046] S11. Dissolve zinc acetate dihydrate and monoethanolamine in ethylene glycol methyl ether at a molar ratio of 1:1 to prepare a zinc acetate solution with a concentration of 0.075mol / L, seal it and place it in a water bath with a constant temperature of 60°C for magnetic stirring for 3 Hours, a colorless transparent sol was obtained, which was left to stand for 24 hours before use; the colorless transparent sol was spin-coated on the cleaned FTO conductive glass at a speed of 5000r / min, and then heat-treated at 300°C for 30 minutes. The coating-heat treatment step was repeated 3 times; finally, heat treatment was per...

Embodiment 2

[0050] A preparation method of a dye-sensitized solar cell ZnO composite photoanode, which is basically the same as the steps of the above-mentioned embodiment 1, the difference is that in the S22 step of the present embodiment, the aqueous solution of zinc nitrate hexahydrate and hexamethylenetetramine The concentration was changed to 0.025mol / L, and a ZnO nanowire array with a length of about 6.0 μm was obtained.

[0051] That is, the specific operation of S22 is as follows:

[0052] Aqueous solutions of 0.025 mol / L zinc nitrate hexahydrate and 0.025 mol / L hexamethylenetetramine were respectively prepared, mixed in equal volumes, and then used as a growth solution for growing ZnO nanowire arrays and put into glass bottles with screw caps. Suspend the above-mentioned FTO conductive glass deposited with the ZnO nanoparticle layer in the growth solution with the ZnO nanoparticle layer facing down, close the bottle cap tightly, put it in an oven and heat it at a constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com