A kind of iron-based soft magnetic composite material and preparation method thereof

A soft magnetic composite material, iron-based technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of high sintering strength, high compressibility, etc., and achieve excellent magnetic properties, high compressibility, soft magnetic properties. optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

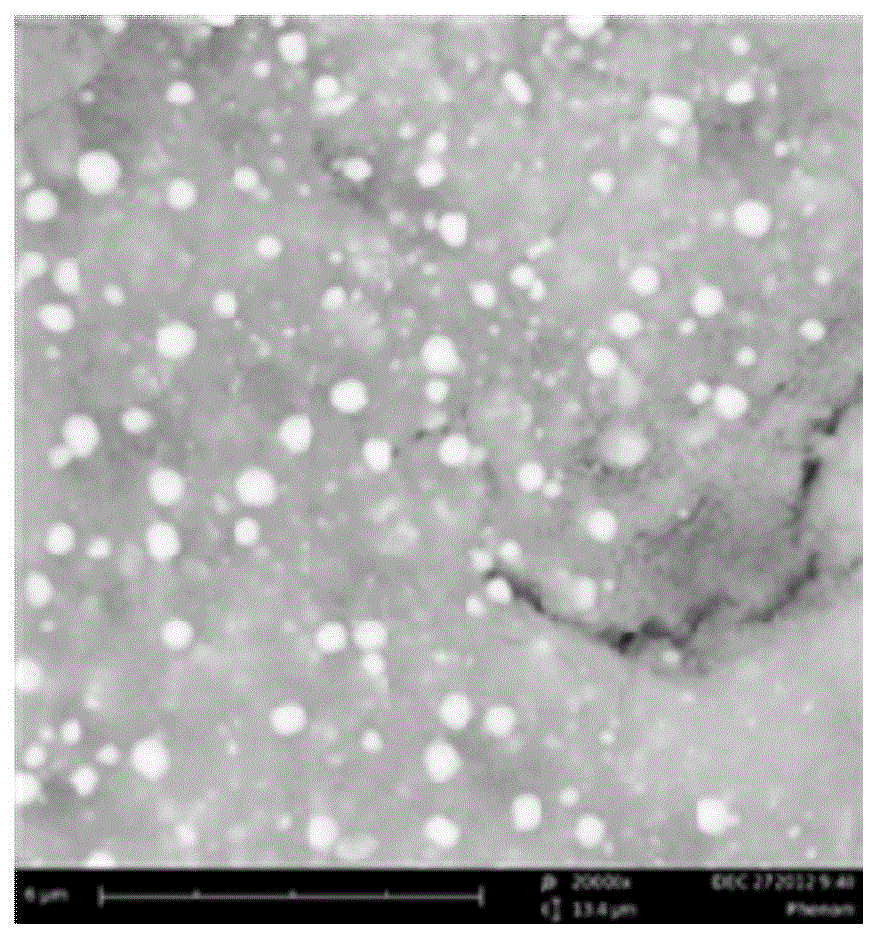

[0023] The iron-based powders used in the examples of the present invention are common water-atomized pure iron powders purchased commercially. For example, the iron powder with a grade of 300W is preferred, among which the iron powder with a particle size within the range of 30-50 μm is the raw material for the high-frequency soft magnetic powder core, and an inorganic substance with a particle size within the range of 50-500 nm is selected as ultra-fine insulating spacer powder. Nano-alumina is preferred, and the two powders are mixed by stirring, wherein the mass percentage of nano-inorganic powder is 0.8%.

[0024] The uniformly mixed iron powder raw materials are put into a mesh belt heating furnace for heating and annealing, and the holding temperature is controlled within the range of 900-1100 °C, preferably 1000 °C here, and the holding time is 30 minutes. A non-oxidizing atmosphere was maintained in the furnace during heating and cooling to room temperature. The obta...

Embodiment 2

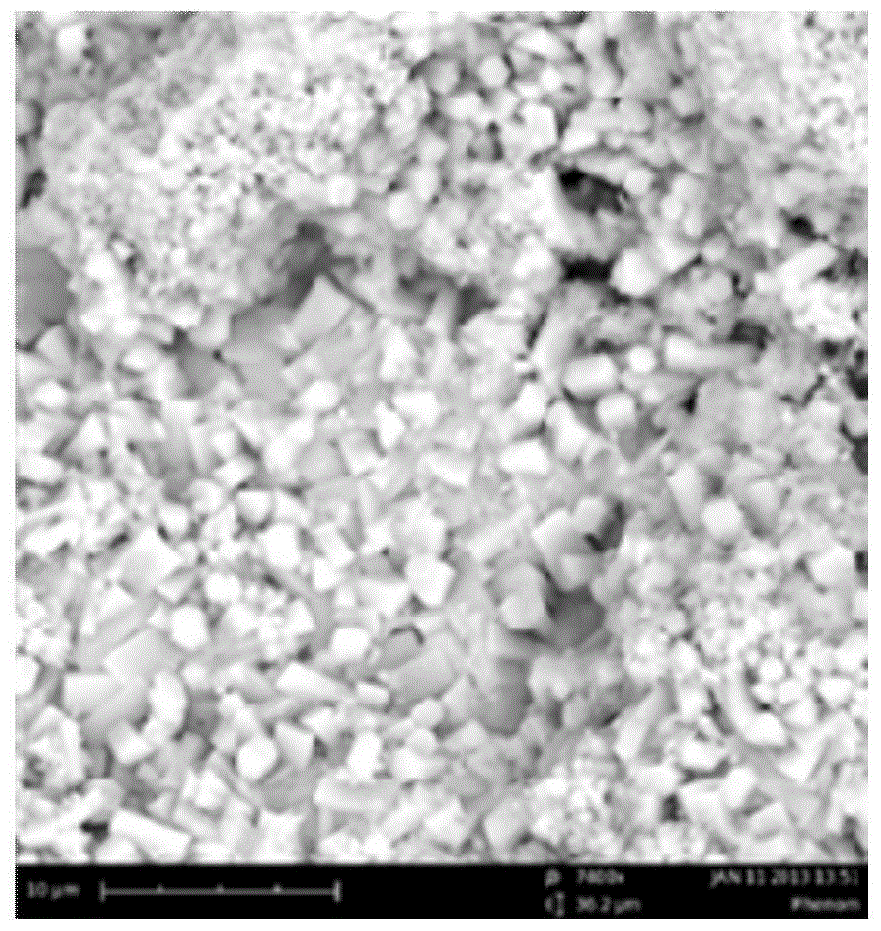

[0029] Choose ordinary water atomized pure iron powder, among which the iron powder with a particle size in the range of 100-280 μm is preferred as the raw material for low-frequency soft magnetic powder cores, more preferably the iron powder content of 100-150 μm is not more than 3%, and the iron powder with a particle size of 150-180 μm The content of iron powder is not more than 16%, and the rest is 180-280μm iron powder. Another inorganic substance with a particle size range of 50-500nm is ultra-fine insulating spacer powder. Here, nano-alumina is preferred. The two powders are mixed by stirring, and the mass percentage of nano-inorganic powder does not exceed 0.5%.

[0030] The uniformly mixed iron powder raw materials are put into a mesh belt heating furnace for heating and annealing, and the holding temperature is controlled within the range of 900-1100°C, preferably 1050°C here, and holding for 30 minutes. A non-oxidizing atmosphere was maintained in the furnace during...

Embodiment 3

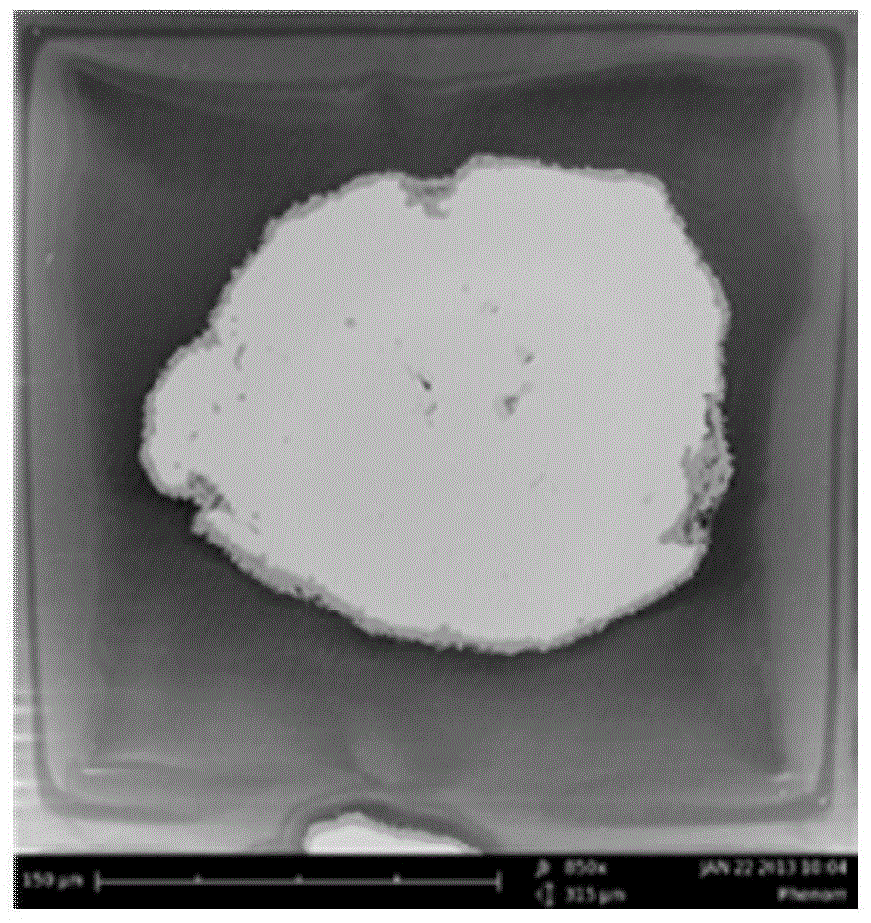

[0035]Ordinary water atomized iron powder is selected, among which the iron powder with a particle size within the range of 100-280 μm is preferred as the raw material, and an inorganic substance with a particle size within the range of 50-500 nm is selected as ultra-fine insulating powder. Here, nano-silicon oxide is preferred. The powders are stirred and mixed, and the mass percentage of the nano-inorganic powder does not exceed 0.5%.

[0036] The uniformly mixed iron powder raw materials are put into a mesh belt heating furnace for heating and annealing, and the holding temperature is controlled within the range of 900-1100°C, preferably 1050°C here, and holding for 30 minutes. A non-oxidizing atmosphere was maintained in the furnace during heating and cooling to room temperature.

[0037] After the above mixed powder is processed, add a certain amount of iron-based phosphating solution by spraying. Here, the SD302 iron-based room temperature phosphating solution purchased ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com