Method for producing environmental-friendly wallboard

A production method and wallboard technology, applied in chemical instruments and methods, manufacturing tools, clay preparation devices, etc., can solve the problems of destroying the natural environment, difficulty in building masonry, and high cost, and achieve environmental pollution control, agricultural land protection, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

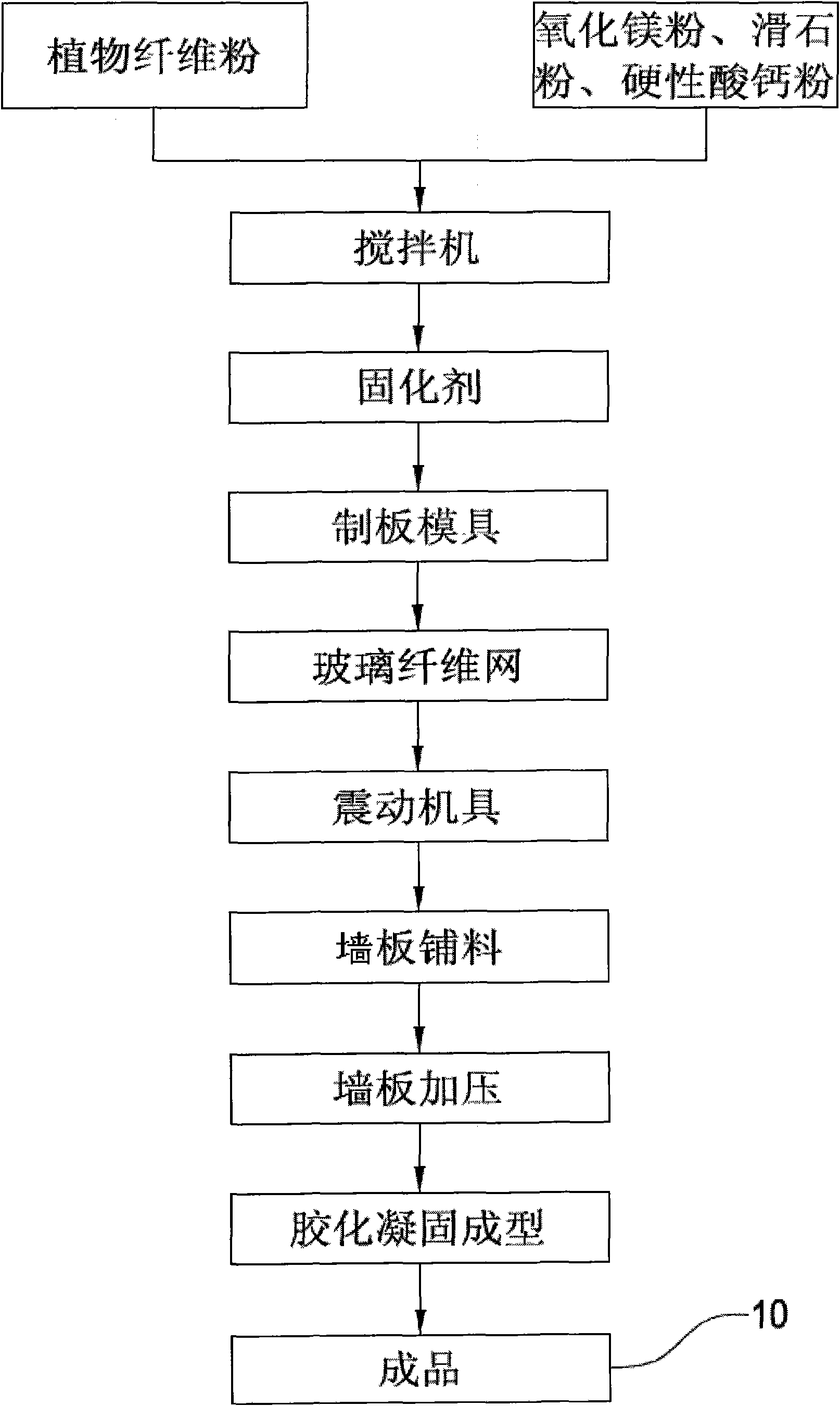

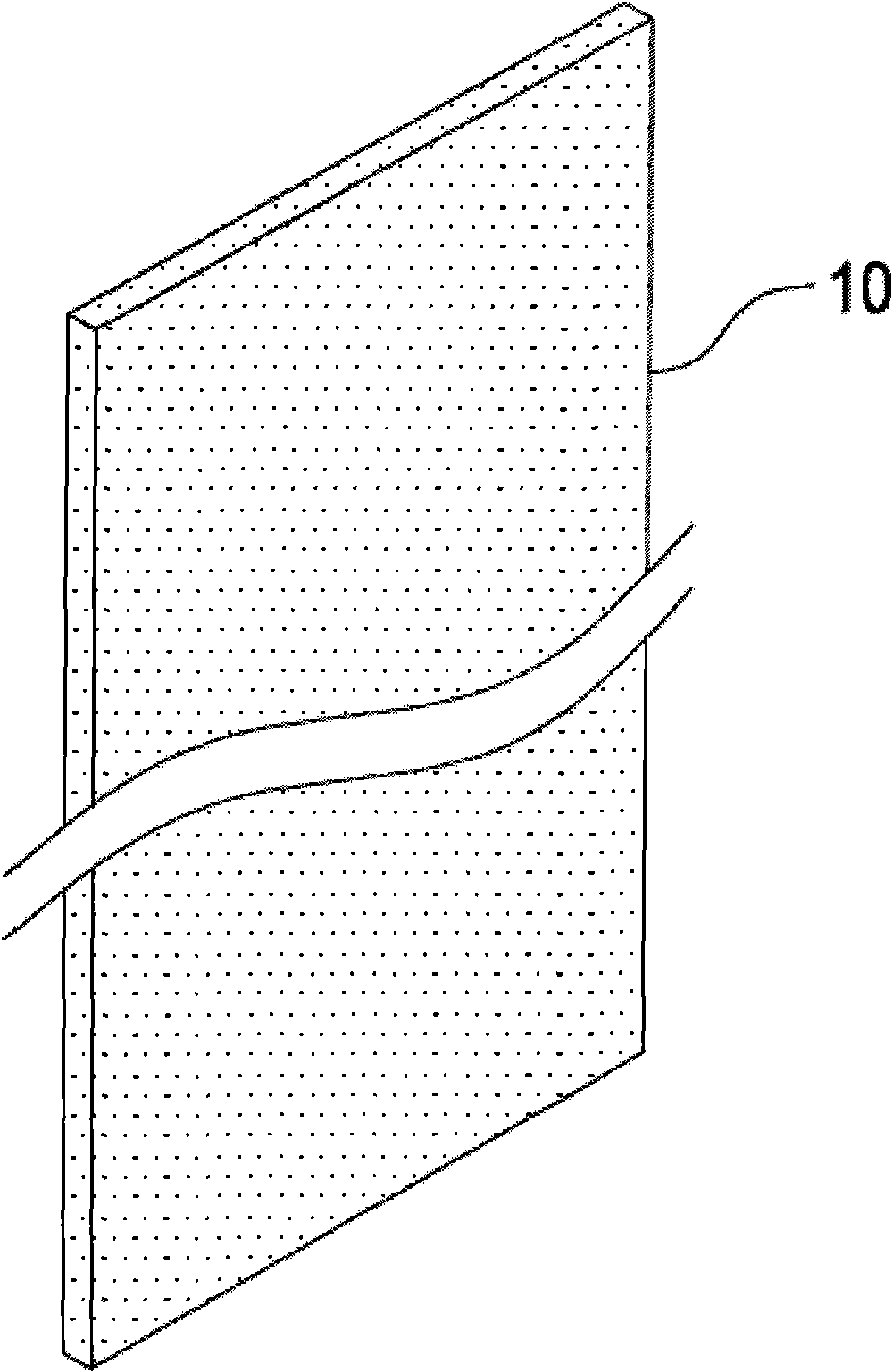

[0019] see figure 1 and figure 2 As shown, it is a flow chart of steps and a finished product completion diagram of the environmental protection wallboard manufacturing method provided by the present invention, and its steps include:

[0020] Step 1: Stir the plant fiber powder, magnesium oxide powder, talc powder and hard acid calcium powder through a mixer to form raw materials; the plant fiber powder can be ground into powder, granule or segmented form according to the use requirements; the plant The material of the fiber powder can be corn stalks; the plant fiber powder can be mixed with corn stalks and other plants at the same time, such as: wheat straw, rice, coconut shell, cotton stalks, weed branches, waste wood chips and other plants; The weight percent of the components in the mixture is: 25-35 percent of plant fiber powder, 10-15 percent of magnesium oxide powder and talcum powder, and 10-15 percent of hard acid calcium powder.

[0021] Step 2: After stirring the...

Embodiment 2

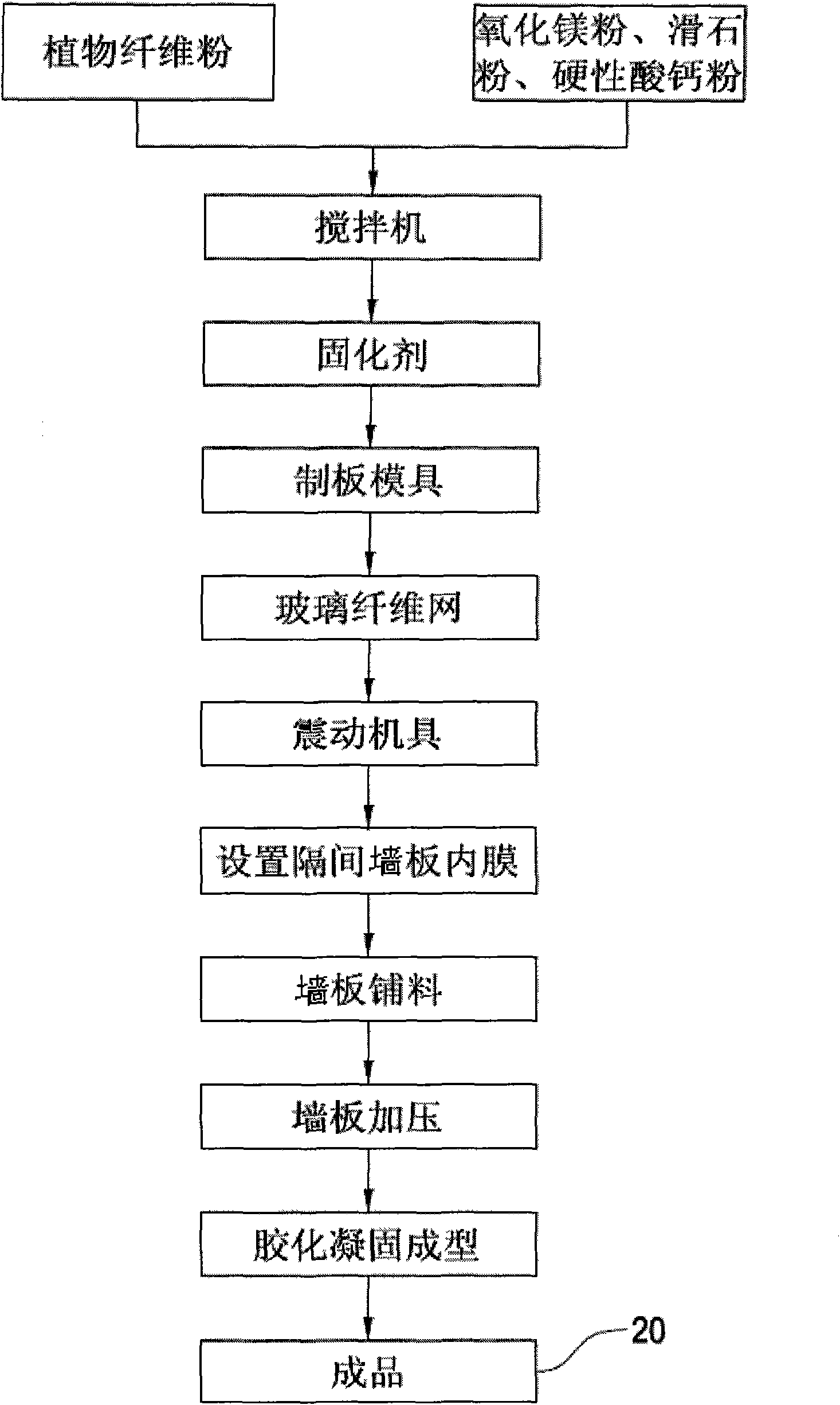

[0027] see image 3 , Figure 4 and Figure 5 As shown, it is a flow chart of steps and a finished product completion diagram of another embodiment of the method for making the environmental protection wallboard. The steps include:

[0028] Step 1: Stir the plant fiber powder, magnesium oxide powder, talc powder and hard acid calcium powder through a mixer to form raw materials; the plant fiber powder can be ground into powder, granule or segmented form according to the use requirements; the plant The material of the fiber powder can be corn stalks; the plant fiber powder can be mixed with corn stalks and other plants at the same time, such as: wheat straw, rice, coconut shell, cotton stalks, weed branches, waste wood chips and other plants; The weight percentage of the components in the mixture is: 25-35% of plant fiber powder, 10-15% of magnesium oxide powder and talc powder, 10-15% of calcium hard acid powder;

[0029] Step 2: After stirring the raw materials for a perio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com