Geopolymer permeable brick and preparation method thereof

A technology of geopolymers and permeable bricks, applied in cement production, etc., can solve problems affecting performance, complicated process, pressure, etc., and achieve the effects of no pressure forming, low energy consumption for preparation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An embodiment of the present invention provides a geopolymer permeable brick, including a base layer and a finishing layer, the base layer includes aggregate A, cementitious material A and an activator, and the decorative layer includes aggregate B, cementitious material B and stimulator.

[0028] The mass fraction of aggregate A is 78% to 84%. Aggregate A is graded by crushed stones of two particle sizes. One crushed stone has a particle size of 4.75-9.5mm and a mass fraction of 55% to 65%. ; Another crushed stone has a particle size of 9.5-15mm and a mass fraction of 35%-45%.

[0029] The mass fraction of the cementitious material A is 16%-24%. The cementitious material A is uniformly mixed with fly ash and slag. The mass fraction of the fly ash is 10%-14%. The mass fraction of the slag is 6% to 8%. The fly ash is fluidized bed fly ash, and the slag is granulated blast furnace slag.

[0030] The sum of the mass fractions of the aggregate A and the cementitious mate...

Embodiment 2

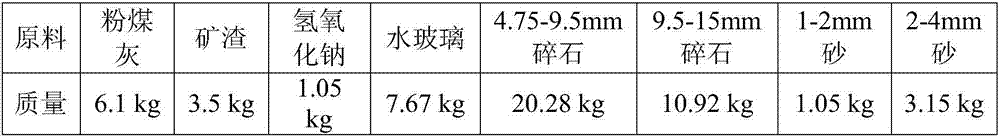

[0044] The embodiment of the present invention provides a geopolymer permeable brick, and the raw material composition of the permeable brick is as follows:

[0045]

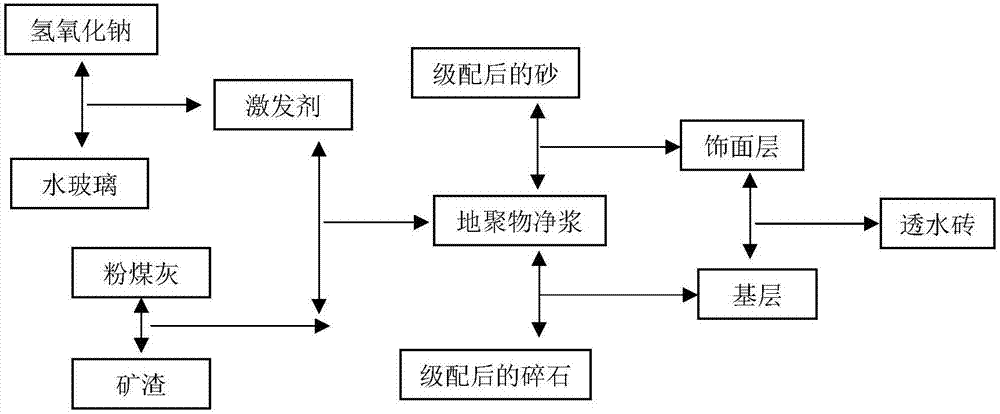

[0046] Please refer to figure 1 , a preparation method of geopolymer permeable brick, comprising the following steps:

[0047] (1) prepare activator, dissolve 1.05kg sodium hydroxide in 7.67kg water glass, after stirring until sodium hydroxide dissolves completely, promptly make activator, be cooled to normal temperature, for subsequent use;

[0048] (2) Put 20.28kg of 4.75-9.5mm crushed stone and 10.92kg of 9.5-15mm crushed stone into the concrete mixer, mix and stir for 1min; add 5.6kg of fly ash and 3.2kg of slag into the concrete mixer, and mix with the graded Mix and stir for 1 minute, then add 8.0 kg of activator, and mix and stir for 3 minutes to obtain the base material for preparing geopolymer permeable bricks; the fly ash is fluidized bed fly ash, and the slag is granulated blast furnace slag;

[00...

Embodiment 3

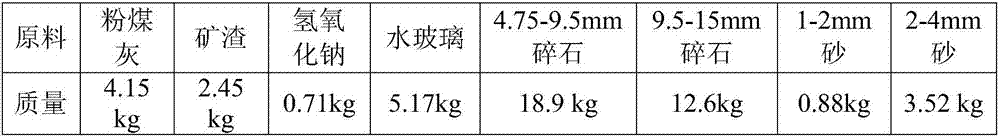

[0055] The embodiment of the present invention provides a geopolymer permeable brick, and the raw material composition of the permeable brick is as follows:

[0056]

[0057] Please refer to figure 1 , a preparation method of geopolymer permeable brick, comprising the following steps:

[0058] (1) prepare activator, dissolve 0.71kg sodium hydroxide in 5.17kg water glass, after stirring until sodium hydroxide dissolves completely, promptly make activator, be cooled to normal temperature, for subsequent use;

[0059] (2) Add 18.9kg of crushed stones of 4.75-9.5mm and 12.6kg of crushed stones of 9.5-15mm into the concrete mixer, mix and stir for 1min; add 3.75kg of fly ash and 2.25kg of slag into the concrete mixer, and mix Mix and stir for 1 min, then add 5.4 kg of activator, and mix and stir for 3 min to obtain the base material for preparing geopolymer permeable bricks; the fly ash is fluidized bed fly ash, and the slag is granulated blast furnace slag;

[0060] (3) Pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com