Method for preparing nano-cerium oxide and zirconia solid solution

A technology of nano-cerium oxide and zirconia, applied in chemical instruments and methods, zirconia, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as easy hardening, pollution, and long time, and achieve particle size Uniform diameter distribution, high chemical activity, high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

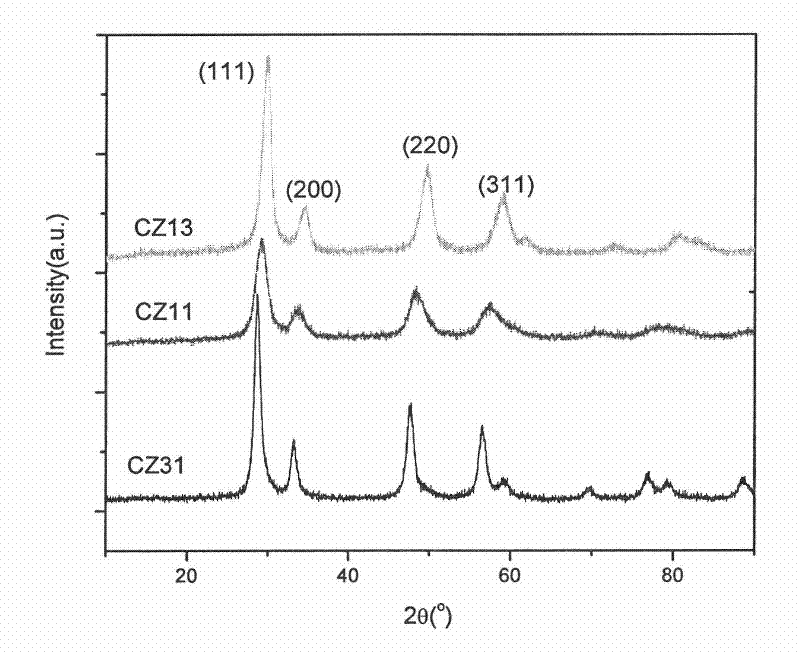

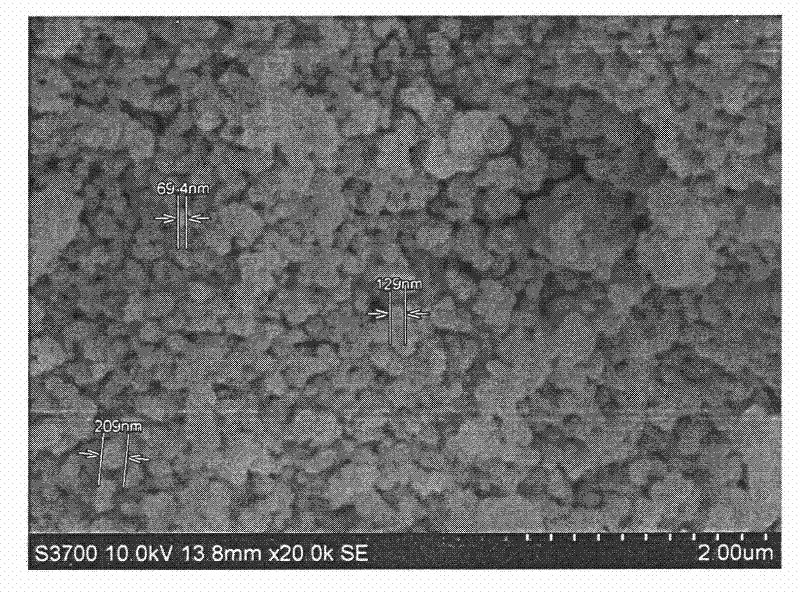

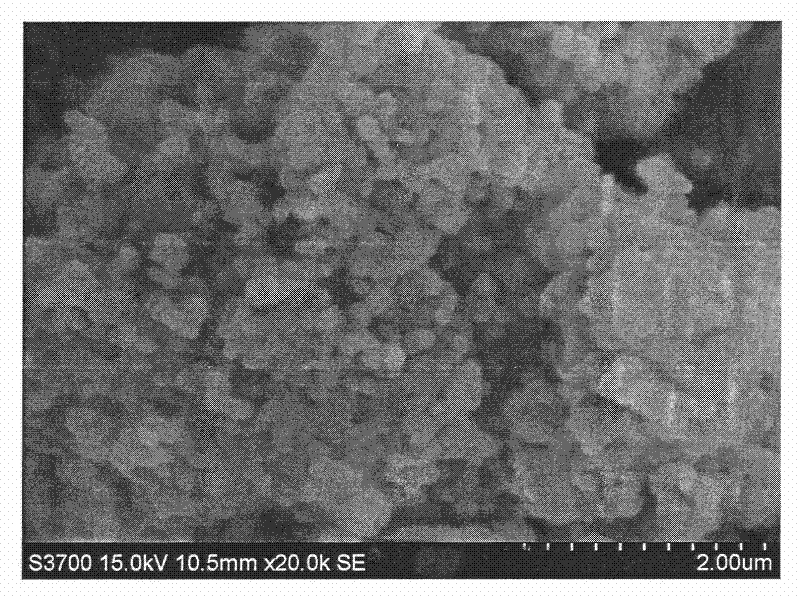

[0033] Using the sol-gel method: the source of cerium in the raw material is cerium nitrate Ce(NO 3 ) 3 ·6H 2 O, the zirconium source is ZrO(NO 3 ) 2 2H 2 O. The surfactant is sodium dodecylbenzenesulfonate. Add zirconyl nitrate solution with a concentration of 0.1 mol / L to the cerium nitrate solution at a concentration of 0.1 mol / L, and the molar ratio of cerium nitrate to zirconyl nitrate is 1:3. Aqueous ammonia at a concentration of 1 mol / L was added to the mixture of the two solutions to adjust the pH value to 9, and then the solution was adjusted to 120° C. and maintained for 6 hours. After filtering and washing for many times, pure hydroxide precipitates are obtained, and the precipitates are subjected to heat treatment and aging. After the precipitation, the precipitation particles with complete crystal form are obtained through heat treatment, and the precipitation is more complete and stable. The temperature of the treatment is 120° C., and the time is 6 hours....

Embodiment 2

[0037] Using sol-gel method: cerium source is cerium nitrate Ce(NO 3 ) 3·6H 2 O, the zirconium source is ZrO(NO 3 ) 2 2H 2 O, the surfactant is sodium dodecylbenzenesulfonate, 0.1 mol / L zirconyl nitrate solution is added to the 1 mol / L cerium nitrate solution, and the molar ratio of cerium nitrate to zirconyl nitrate is 1:1. Add 0.1 mol / L ammonia water to the mixture of the two solutions to adjust the pH value to 10, then adjust the solution to 120° C. and keep it for 6 hours. After filtering and washing for many times, pure hydroxide precipitates were obtained, and the precipitates were subjected to heat treatment at a temperature of 100° C. for 0.5 hours. Then the precipitate is dissolved in 0.1mol / L nitric acid, the sum of the concentrations of the cerium-zirconium composite oxide is adjusted to 35g / L, and the surfactant sodium dodecylbenzenesulfonate is added in an amount of cerium-zirconium composite oxide 0.5% by weight, and transferred to a three-necked flask at 1...

Embodiment 3

[0041] Using sol-gel method: cerium source is cerium nitrate Ce(NO 3 ) 3 ·6H 2 O, the zirconium source is ZrO(NO 3 ) 2 2H 2 O, the surfactant is sodium dodecylbenzenesulfonate, add 1 mol / L zirconyl nitrate solution to the 0.1 mol / L cerium nitrate solution, and the molar ratio of cerium nitrate to zirconyl nitrate is 3:1. Add 1 mol / L ammonia water to the mixture of the two solutions to adjust the pH value to 9, then adjust the solution to 120° C. and maintain it for 6 hours. After filtering and washing for many times, pure hydroxide precipitates were obtained, and the precipitates were heat-treated at a temperature of 300° C. for 24 hours. Then the precipitate is dissolved in 1mol / L nitric acid, the sum of the concentration of the cerium-zirconium composite oxide is adjusted to 35g / L, and the surfactant sodium dodecylbenzenesulfonate is added in an amount equal to the weight of the cerium-zirconium composite oxide 0.5% of the solution, and transferred to a three-neck flas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com