A kind of preparation method of graphene-coated manganese dioxide composite wave absorbing agent

A technology of graphene coating and manganese dioxide, applied in the direction of graphene, manganese oxide/manganese hydroxide, nanotechnology for materials and surface science, etc., can solve the problem of poor composite interface performance and weak bonding force of heterogeneous materials , secondary agglomeration and other issues, to achieve the effects of optimized impedance matching performance, good dispersion performance, and excellent composite interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

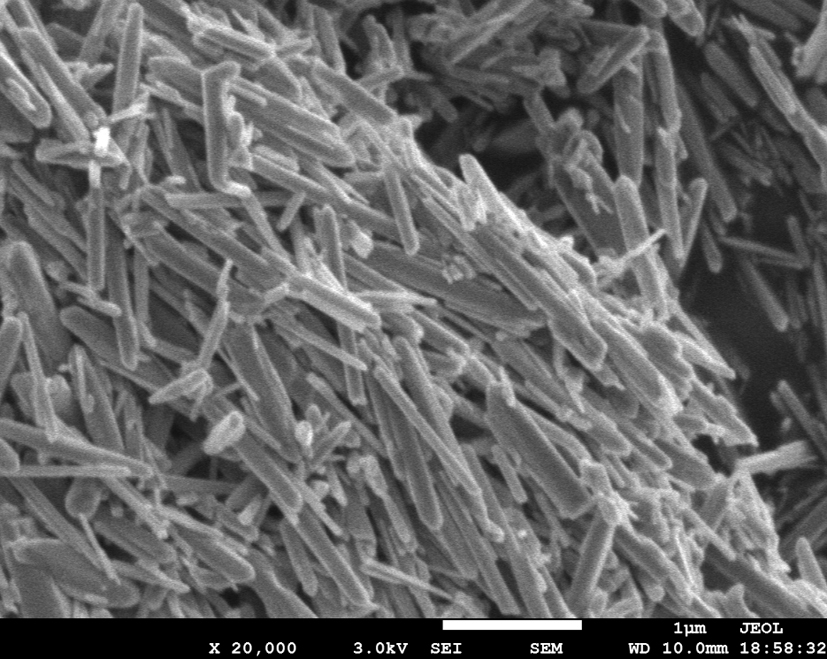

Image

Examples

Embodiment 1

[0023] A preparation method of graphene-coated manganese dioxide composite wave absorbing agent, comprising the following steps:

[0024] S1, take by weighing manganese sulfate and ammonium persulfate of certain quality respectively, wherein the mol ratio of manganese sulfate and ammonium persulfate is 0.1:1, leave it for later use;

[0025] S2. Slowly add the manganese sulfate weighed in step S1 into the graphene oxide aqueous solution with a concentration of 3 mg / mL for 3 minutes, and at the same time perform magnetic stirring for 30 minutes to form a gel, which will be reserved for later steps use;

[0026] S3. Slowly add the ammonium persulfate weighed in step S1 into the gel prepared in step S2 at a uniform speed for 15 minutes, and at the same time perform magnetic stirring for 1 hour to prepare a mixed solution, which will be used in the next step;

[0027] S4, subjecting the mixed solution prepared in step S3 to hydrothermal treatment, the heating temperature is 100° ...

Embodiment 2

[0030] A preparation method of graphene-coated manganese dioxide composite wave absorbing agent, comprising the following steps:

[0031] S1, take by weighing manganese sulfate and ammonium persulfate of certain quality respectively, and wherein the mol ratio of manganese sulfate and ammonium persulfate is 10:1, leave it for later use;

[0032] S2. Slowly add the manganese sulfate weighed in step S1 into the graphene oxide aqueous solution with a concentration of 0.5 mg / mL for 5 minutes, and at the same time, perform magnetic stirring for 50 minutes to make a gel and leave it for later Step use;

[0033] S3. Slowly add the ammonium persulfate weighed in step S1 to the gel prepared in step S2 at a uniform speed for 25 minutes, and at the same time perform magnetic stirring for 30 minutes to prepare a mixed solution, which will be used in the next step;

[0034] S4, subjecting the mixed solution prepared in step S3 to hydrothermal treatment, the heating temperature is 120° C., ...

Embodiment 3

[0037] A preparation method of graphene-coated manganese dioxide composite wave absorbing agent, comprising the following steps:

[0038] S1, take by weighing manganese sulfate and ammonium persulfate of a certain quality respectively, wherein the mol ratio of manganese sulfate and ammonium persulfate is 6:1, leave it for later use;

[0039] S2. Slowly add the manganese sulfate weighed in step S1 into the graphene oxide aqueous solution with a concentration of 10 mg / mL for 30 min, and at the same time perform magnetic stirring for 1 h to form a gel, which will be reserved for the next step use;

[0040] S3. Slowly add the ammonium persulfate weighed in step S1 into the gel prepared in step S2 at a uniform speed for 10 minutes, and magnetically stir at the same time for 1.2 hours to prepare a mixed solution, which will be used in the next step;

[0041] S4, subjecting the mixed solution prepared in step S3 to hydrothermal treatment, the heating temperature is 200° C., and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com