Preparation method and application of composite metal oxide catalysts for coal gasification

A composite metal and catalyst technology, which is applied in the field of composite metal oxide catalyst preparation, can solve the problems of recycling secondary pollution, high catalyst price, and restricting the industrialization process, so as to reduce the recycling cost, improve the gasification rate, and solve the problems in the furnace. The effect of slagging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

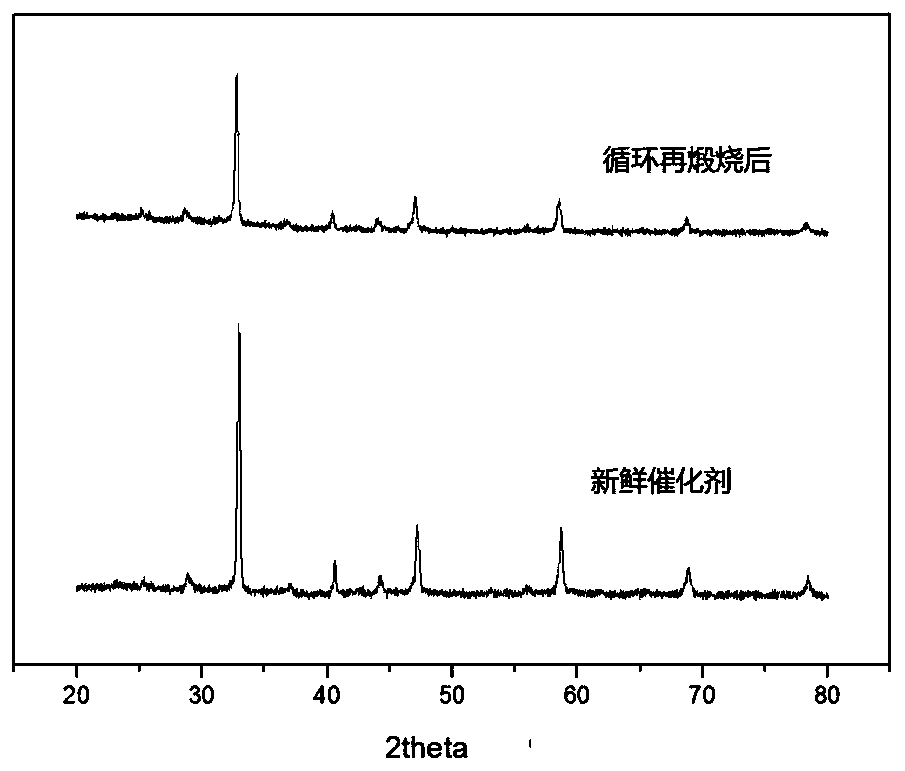

[0042] Composite Metal Oxide Catalyst La for Coal Gasification 0.5 Sr 0.5 Fe 0.2 co 0.8 o 3-δ Preparation of:

[0043] 1) Weigh lanthanum nitrate, strontium nitrate, iron nitrate and cobalt nitrate respectively according to the molar ratio of 0.5:0.5:0.2:0.8 (5:5:2:8);

[0044] 2) adding lanthanum nitrate, strontium nitrate, ferric nitrate, and cobalt nitrate into water and mixing uniformly to form an aqueous metal nitrate solution;

[0045] 3) take EDTA, citric acid and metal nitrate aqueous solution by weighing the molar ratio 1:1:1 of the total molar number of metal ions in EDTA, citric acid and the above-mentioned metal nitrate aqueous solution;

[0046] 4) Mix EDTA and citric acid, adjust the pH value to 8, and place in a constant temperature water bath with a temperature of 75°C to stir evenly to form a precursor solution;

[0047] 5) adding the metal nitrate aqueous solution to the above precursor solution, and continuing to stir until a wet gel is formed;

[004...

Embodiment 2

[0052] Composite metal oxide catalyst La 0.1 Sr 0.9 co 0.8 Fe 0.2 o3-δ Preparation of:

[0053] 1) Weigh lanthanum nitrate, strontium nitrate, cobalt nitrate, and iron nitrate respectively according to the molar ratio of 0.1:0.9:0.8:0.2;

[0054] 2) adding lanthanum nitrate, strontium nitrate, cobalt nitrate and ferric nitrate into distilled water, mixing and stirring to form a metal nitrate aqueous solution;

[0055] 3) take EDTA, citric acid and metal nitrate aqueous solution by weighing the molar ratio 1:1.2:1 of the total molar number of metal ions in EDTA, citric acid and the above-mentioned metal nitrate aqueous solution;

[0056] 4) Mix EDTA and citric acid, adjust the pH value to 8, and place in a constant temperature water bath with a temperature of 75°C to stir evenly to form a precursor solution;

[0057] 5) adding the metal nitrate aqueous solution to the above precursor solution, and continuing to stir until a wet gel is formed;

[0058] 6) drying the wet ge...

Embodiment 3

[0062] Composite metal oxide catalyst La 0.1 Ba 0.9 Fe 0.1 co 0.9 o 3-δ Preparation of:

[0063] 1) Weigh lanthanum nitrate, barium nitrate, iron nitrate, manganese nitrate respectively according to molar ratio 0.1:0.9:0.1:0.9 (1:9:1:9);

[0064] 2) adding lanthanum nitrate, barium nitrate, iron nitrate, and manganese nitrate into water and mixing uniformly to form an aqueous metal nitrate solution;

[0065] 3) take EDTA, citric acid and metal nitrate aqueous solution by weighing the molar ratio 1:1.2:1 of the total molar number of metal ions in EDTA, citric acid and the above-mentioned metal nitrate aqueous solution;

[0066] 4) Mix EDTA and citric acid, adjust the pH value to 8, and place in a constant temperature water bath with a temperature of 80°C to stir evenly, and prepare a precursor solution;

[0067] 5) adding the metal nitrate aqueous solution to the above precursor solution, and continuing to stir until a wet gel is formed;

[0068] 6) drying the wet gel at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com