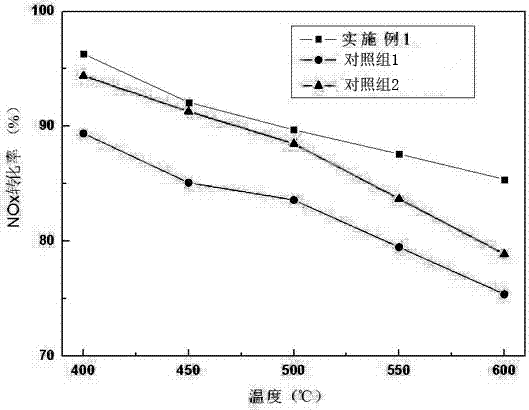

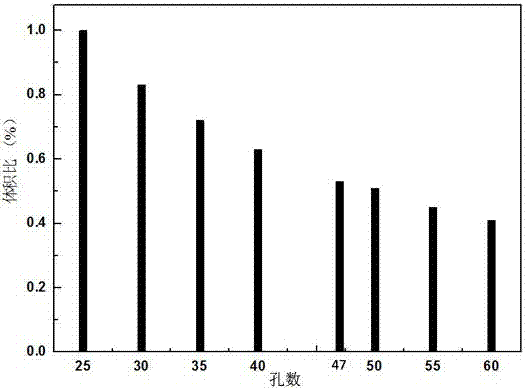

Small-pore catalyst for fuel gas denitration and preparation method

A technology with small pore size and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc. The effect of easy industrial production, easy release, and large number of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A small-aperture catalyst for gas denitrification, prepared by the following method:

[0024] 1) Ball milling: Mix 60g of carrier aluminum titanate, 30g of zirconia and 10g of tungsten oxide evenly, then add 1.22g of nickel nitrate, 0.69g of chromium nitrate and 0.97g of ruthenium nitrate, 0.3g of ethyl orthosilicate, hydroxypropyl Mix 0.1g of methyl cellulose, 0.1g of tung oil, 0.1g of aluminum dihydrogen phosphate, 0.05g of graphite and 0.05g of calcined kaolin, then add 150g of deionized water, use d 90 A grinding body with a particle size of 4.8 μm was ball milled for 8 hours.

[0025] 2) Kneading: kneading the mixture in step 1) for 240 minutes to obtain mud, the mud reaches a moisture content of 30.5% and a plasticity index of 9-12;

[0026] 3) Embryo making: put the mud in step 2) into a medium with a vacuum degree of -0.09 MPa and practice the mud three times, stale at room temperature for 36 hours, pressurize at 15 MPa and filter once with a 200-mesh screen, k...

Embodiment 2

[0031] A small-aperture catalyst for gas denitrification, prepared by the following method:

[0032] 1) Ball milling: Stir and mix the carrier aluminum titanate 50g, zirconia 30g and tungsten oxide 20g evenly, then add 2.07g nickel sulfate, 1.38g chromium nitrate and 1.27g ruthenium chloride, 0.1g ethyl orthosilicate, hydroxypropyl 0.05g of methyl cellulose, 0.5g of tung oil, 0.1g of aluminum dihydrogen phosphate, 0.05g of graphite, and 0.1g of calcined kaolin were mixed, and then 250g of deionized water was added. 90 A grinding body with a particle size of 4.5 μm was ball milled for 12 hours.

[0033] 2) Kneading: kneading the mixture in step 1) for 120 minutes to obtain a mud material, the mud material has a moisture content of 29.3% and a plasticity index of 9;

[0034] 3) Embryo making: put the mud in step 2) into a medium with a vacuum degree of -0.095 MPa and practice the mud three times, stale at room temperature for 72 hours, pressurize at 8 MPa and filter it with a 4...

Embodiment 3

[0039] A small-aperture catalyst for gas denitrification, prepared by the following method:

[0040]1) Ball milling: Stir and mix the carrier aluminum titanate 60g, zirconia 30g and tungsten oxide 10g evenly, then add 60g aluminum titanate, 30g zirconia and 10g tungsten oxide, 0.87g nickel chloride, 1.59g chromium chloride and 0.85 g ruthenium acetate, 0.3g tetraethyl orthosilicate, 0.1g hydroxypropyl methylcellulose, 0.3g tung oil, 0.1g aluminum dihydrogen phosphate, 0.1g graphite and 0.1g calcined kaolin, add 190g deionized water after mixing , using d 90 A grinding body with a particle size of 3.9 μm was ball milled for 10 h.

[0041] 2) Kneading: Kneading the mixture in step 1) for 200 minutes to obtain a mud material, the mud material has a moisture content of 28.9% and a plasticity index of 11;

[0042] 3) Embryo making: put the mud in step 2) into a medium with a vacuum degree of -0.093 MPa and practice the mud three times, stale at room temperature for 60 hours, pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com