Multifunctional composite carbon fiber inner liner and preparation method thereof

A composite carbon fiber and multi-functional technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of production process influence, strong constraints, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

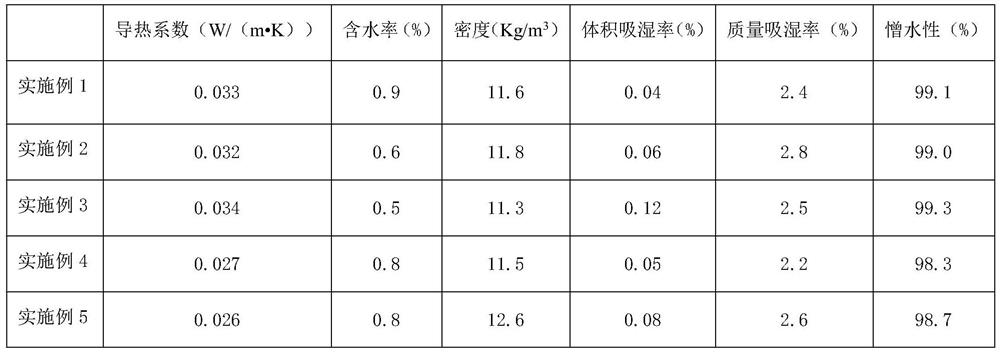

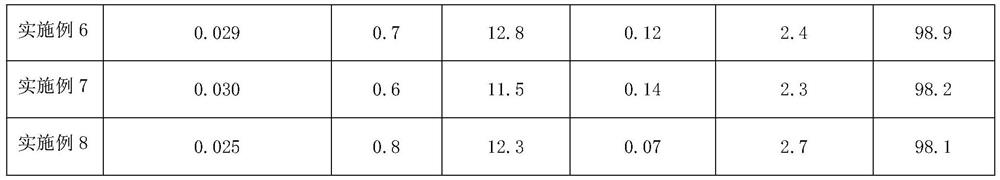

Examples

preparation example Construction

[0026] The technical scheme of the present invention is as follows: a preparation method of a multifunctional composite carbon fiber inner liner; the preparation method includes the following steps:

[0027] S1: Preparation of materials: specifically, carbon fibers, polyester fibers, polyurethane fibers, and phenolic fibers are cut into suitable lengths, and the lengths are preferably between 50-150mm.

[0028] Wherein, the diameters of the carbon fibers, polyester fibers, polyurethane fibers and phenolic fibers are between 3-5 μm, and the thinner carbon fibers can ensure that the various fibers themselves will not be broken by the pressure during the subsequent pressurization process. The squashed situation.

[0029] S2: Mixing materials: Specifically, the carbon fiber, polyester fiber, polyurethane fiber and phenolic resin treated by S1 are initially mixed in a certain proportion, and the preferred ratio is (8-10): (4-5): (4- 5): 1.

[0030] The composite carbon fiber inne...

Embodiment 1

[0043] A preparation method of a multifunctional composite carbon fiber inner liner; the preparation method comprises the steps of:

[0044] S1: Preparation of materials: specifically, carbon fiber, polyester fiber, polyurethane fiber and phenolic resin fiber are cut to a length of 50 mm, and the diameter of the above fiber is 3 μm.

[0045] S2: Mixing: the carbon fiber, polyester fiber, polyurethane fiber and phenolic resin after cutting are mixed in a ratio of 8:4:4:1 to make a mixed fiber.

[0046] S3: Carding, opening and mixing the preliminarily mixed mixed fibers through an opener and a carding machine in sequence, and then spreading them into a mixed fiber layer;

[0047] S4: adding hot-melt adhesive polyamide powder to the mixed fiber layer obtained in step S3, and making the hot-melt adhesive powder enter the mixed fiber layer through the vibration of the vibrator;

[0048] And in this embodiment, the diameter of the hot-melt polyamide powder is 30 μm.

[0049] S5: ...

Embodiment 2

[0052] A preparation method of a multifunctional composite carbon fiber inner liner; the preparation method comprises the steps of:

[0053] S1: Material preparation: Specifically, carbon fibers, polyester fibers, polyurethane fibers, and phenolic fibers are cut to a length of 150 mm, and the diameter of the above fibers is 5 μm.

[0054] S2: Mixing: mix the cut carbon fiber, polyester fiber, polyurethane fiber and phenolic resin in a ratio of 10:5:5:1 to make a mixed fiber.

[0055] S3: Carding, opening and mixing the preliminarily mixed mixed fibers through an opener and a carding machine in sequence, and then spreading them into a mixed fiber layer;

[0056] S4: adding hot-melt adhesive polyester powder to the mixed fiber layer obtained in step S3, and making the hot-melt adhesive polyester powder enter the mixed fiber layer through the vibration of the vibrator;

[0057] And in this embodiment, the diameter of the hot-melt polyester powder is 40 μm.

[0058] S5: Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com