Small-aperture corrugated catalyst for fuel gas denitration, and preparation method thereof

A corrugated, catalyst technology, applied in the field of flue gas denitrification, can solve the problems of increased project cost, difficult extrusion molding, low yield, etc., and achieve the effects of extending service life, enhancing thermal stability, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a small-aperture corrugated catalyst for gas denitrification, which comprises the following raw materials: glass fiber felt as the skeleton substrate, one or both of titanyl sulfate and silicon oxide as the carrier, and heptamolybdic acid One or both of ammonium and cerium salts are additives, and one or more of manganese salts, iron salts, and chromium salts are active component precursors and deionized water; the carrier is 90 parts, and the The active component precursor is 1.6-6.5 parts, the auxiliary agent is 3.8-5.1 parts, and the deionized water is 120-200 parts.

[0033] Further, the mass of the glass fiber mat is 20g.

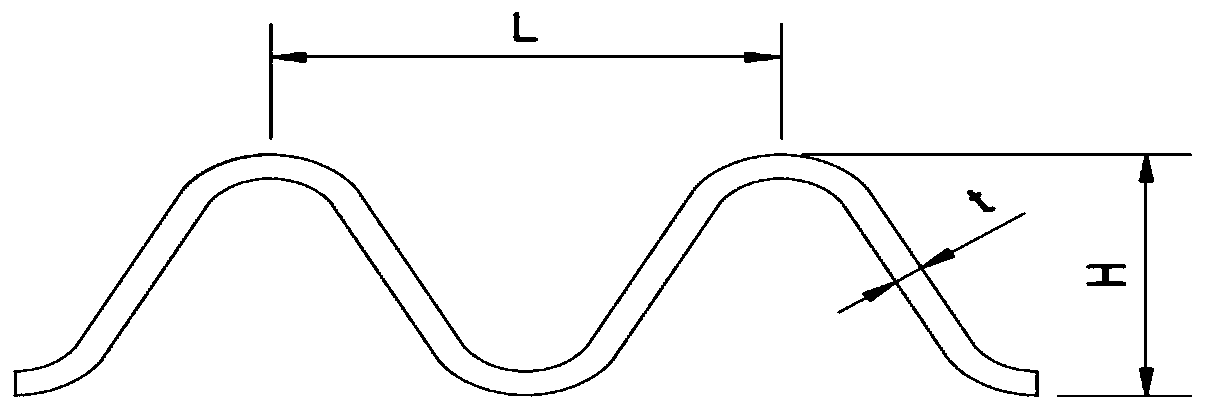

[0034] Further, see figure 1 As shown, the inner wall thickness of the corrugated catalyst is 0.3±0.05mm, the pore diameter of the corrugated catalyst is 1.6-2.0mm, and the wavelength is 3.6mm.

[0035] Further, the number of holes in the corrugated catalyst is 75 holes.

[0036] Further, the specific surface area of ...

Embodiment 2

[0051] The present invention provides another method for preparing a small-aperture corrugated catalyst for gas denitrification, which specifically includes the following steps:

[0052] 1) select 20g of glass fiber thin felt as the skeleton material, adopt molding liquid and manufacture corrugated plate through molding process, and stack described corrugated plate and flat plate into a unit;

[0053] 2) Impregnate the units prepared in step 1) with the mixed solution containing the active ingredient of the catalyst, configure the mixed solution according to the proportion, stir for more than 30 minutes and pour it into the impregnation tank, and carry out the negative pressure impregnation of the units one by one. After the impregnation is completed, put Let it stand on the platform for more than 2 hours; wherein, the configuration ratio of the mixed solution is: 90 parts of carrier, 1.6-6.5 parts of active component precursor, 3.8-5.1 parts of auxiliary agent and 120-200 part...

Embodiment 3

[0064] The present invention also provides a method for preparing a small-aperture corrugated catalyst for gas denitrification, which specifically includes the following steps:

[0065] 1) select 20g of glass fiber thin felt as the skeleton material, adopt molding liquid and manufacture corrugated plate through molding process, and stack described corrugated plate and flat plate into a unit;

[0066] 2) Impregnate the units prepared in step 1) with the mixed solution containing the active ingredient of the catalyst, configure the mixed solution according to the proportion, stir for more than 30 minutes and pour it into the impregnation tank, and carry out the negative pressure impregnation of the units one by one. After the impregnation is completed, put Let it stand on the platform for more than 2 hours; wherein, the configuration ratio of the mixed solution is: 90 parts of carrier, 1.6-6.5 parts of active component precursor, 3.8-5.1 parts of auxiliary agent and 120-200 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com