Preparation method of catalyst capable of catalytically combusting VOCs (volatile organic compounds) containing fluorine and chlorine

A catalytic combustion and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as unsatisfactory catalytic effect, catalyst poisoning and deactivation, loss of active components, etc., and achieve good results Anti-virus ability, repeated use stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

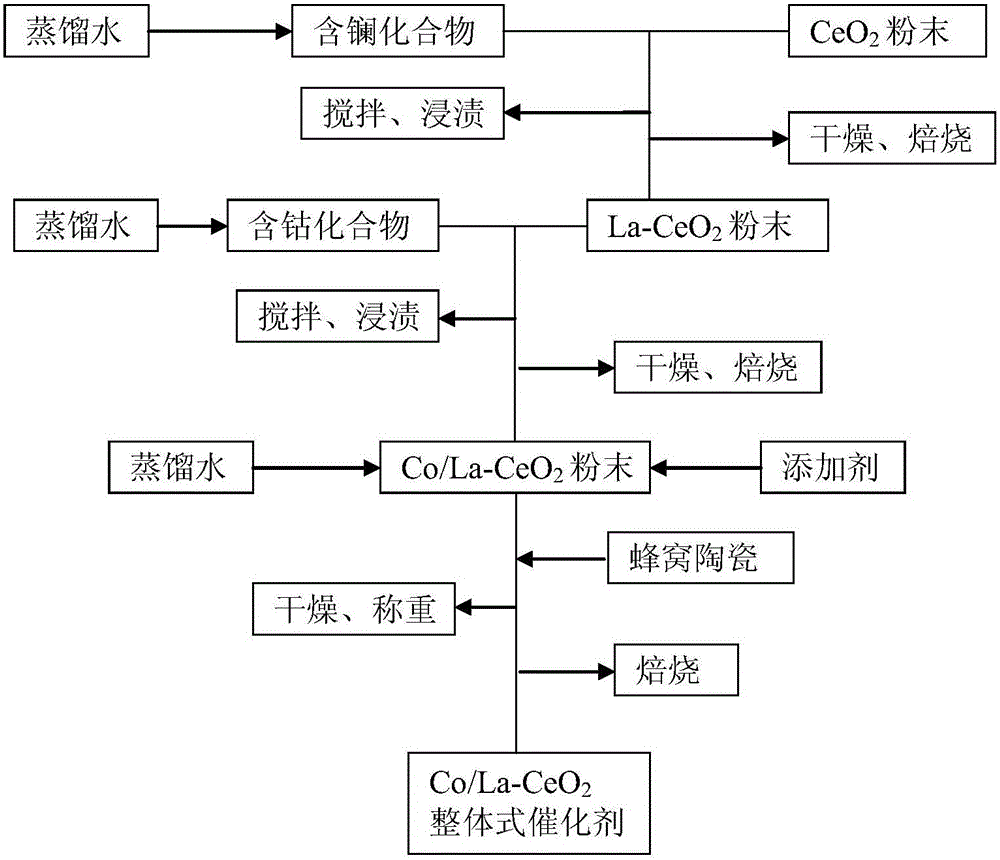

[0022] (1) 0.1981g La(NO 3 ) 3 ·6H 2 O was dissolved in 100 mL of distilled water and stirred until completely dissolved to form an aqueous solution of the lanthanum-containing compound.

[0023] (2) Take 1g CeO 2 The powder was mixed with the solution obtained in (1), stirred by a magnetic stirrer at room temperature for 1 hour, impregnated for 8 hours, evaporated at 50°C, dried at 100°C for 8 hours, calcined at 350°C for 8 hours, and ground to obtain La(5.00wt.%)-CeO 2 Powder, wherein the mass fraction of La is 5.00%.

[0024] (3) 1.2206g Co(CH 3 COO) 2 4H 2 O was dissolved in 100 mL of distilled water and stirred until completely dissolved to form an aqueous solution of cobalt-containing compounds.

[0025] (4) Mix 1 g of the powder obtained in (2) with the solution obtained in (3), stir for 4 hours at room temperature with a magnetic stirrer, impregnate for 16 hours, evaporate at 50°C, dry at 100°C for 8 hours, roast at 350°C for 6 hours, and grind to obtain Co( 20...

Embodiment 2

[0029] (1) Add 0.3000g La(CH 3 COO) 3 4H 2 O was dissolved in 100 mL of distilled water and stirred until completely dissolved to form an aqueous solution of the lanthanum-containing compound.

[0030] (2) Take 1g CeO 2 The powder was mixed with the solution obtained in (1), stirred by a magnetic stirrer at room temperature for 2 hours, impregnated for 10 hours, evaporated at 60°C, dried at 110°C for 7 hours, calcined at 450°C for 7 hours, and ground to obtain La(8.08wt.%)-CeO 2 Powder, wherein the mass fraction of La is 8.08%.

[0031] (3) 1.0000g Co(CH 3 COO) 2 4H 2 O was dissolved in 100 mL of distilled water and stirred until completely dissolved to form an aqueous solution of cobalt-containing compounds.

[0032] (4) Mix 1 g of the powder obtained in (2) with the solution obtained in (3), stir for 3 hours at room temperature with a magnetic stirrer, impregnate for 14 hours, evaporate at 60°C, dry at 110°C for 7 hours, roast at 450°C for 6 hours, and grind to obtain...

Embodiment 3

[0036] (1) Add 0.4000g La(NO 3 ) 3 ·6H 2 O was dissolved in 100 mL of distilled water and stirred until completely dissolved to form an aqueous solution of the lanthanum-containing compound.

[0037] (2) Take 1g CeO 2 The powder was mixed with the solution obtained in (1), stirred by a magnetic stirrer at room temperature for 2 hours, impregnated for 12 hours, evaporated at 70°C, dried at 120°C for 6 hours, calcined at 500°C for 6 hours, and ground to obtain La(9.45wt.%)-CeO 2 Powder, wherein the mass fraction of La is 9.45%.

[0038] (3) 1.0000g Co(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of distilled water and stirred until completely dissolved to form an aqueous solution of cobalt-containing compounds.

[0039] (4) Mix 1 g of the powder obtained in (2) with the solution obtained in (3), stir for 2 hours at room temperature with a magnetic stirrer, impregnate for 12 hours, evaporate at 70°C, dry at 120°C for 6 hours, roast at 500°C for 5 hours, and grind to obtain Co(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com