Lubricant for machining, additive for machining, and machining method

A lubricant and processed technology, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problem of high cost and achieve the effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] The present invention will be described more specifically with reference to examples.

[0083] "Preparation of Lubricants for Machining"

[0084] (1) Sample No.A00~A111 (lubricants for oil-based machining)

[0085] As shown in Table 1, various oil-soluble polymer compounds (additives) were added to the base oil (sample No. A00) to prepare various machining lubricants for aluminum alloys.

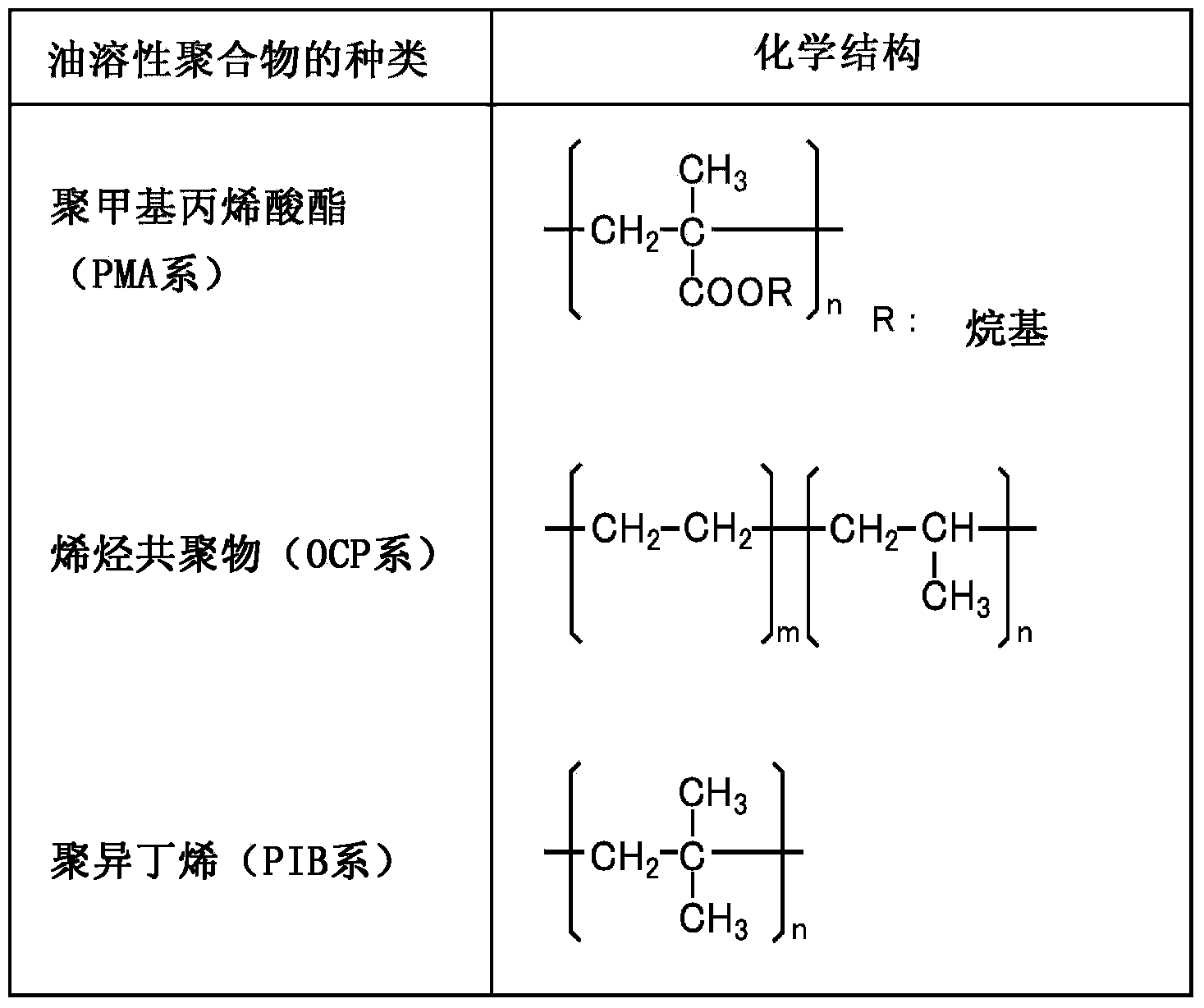

[0086] As the base oil, additive-free mineral oil (Samper 110 / manufactured by Nippon Sun Oil Co., Ltd.) was used. The dynamic viscosity of the base oil is 20.2mm at 40°C 2 / Second. Table 1 shows the structure (main part and functional group) and molecular weight (Mw) of the oil-soluble polymer compound of each sample together. It should be noted that the chemical structure of the polymethacrylate or olefin copolymer as the main part of the oil-soluble polymer compound is as follows: figure 1 shown.

[0087] The amount of the oil-soluble polymer compound added to the base oil is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com