Production method of battery-grade high-purity manganese sulfate

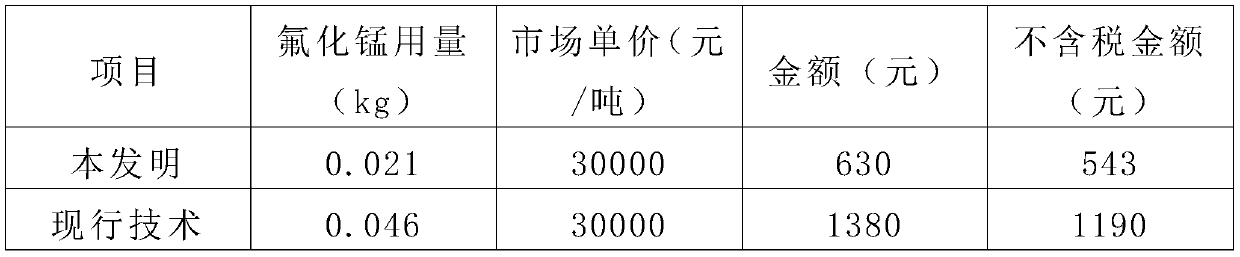

A production method and technology of manganese sulfate, applied in manganese sulfate and other directions, can solve the problems of large consumption of impurity-removing agents, reduce production costs, and a large amount of heat energy, and achieve the effects of controllable product quality, low comprehensive cost, and high fluorine utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

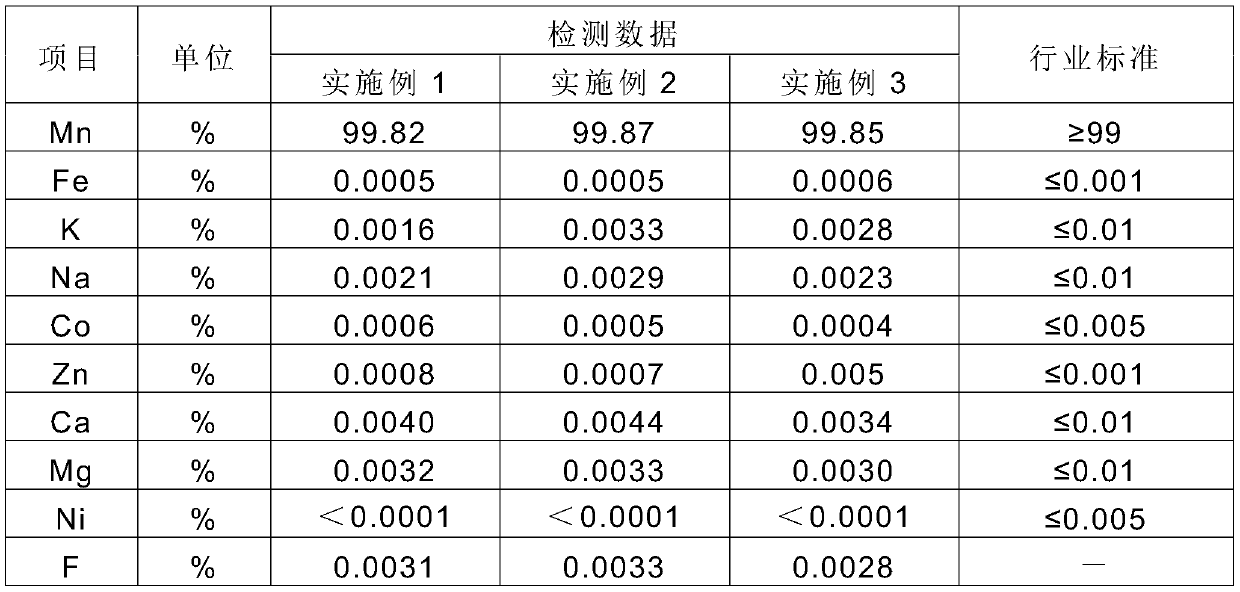

Embodiment 1

[0028] The present embodiment provides a kind of production method of battery grade high-purity manganese sulfate, comprises the following steps:

[0029] a. Dissolve the ordinary manganese sulfate particles containing impurities in the manganese sulfate compound solution from the cheap manganese sulfate factory, adjust the manganese sulfate aqueous solution with a concentration of 300g / L, adjust the pH value to 1.5, heat the solution to above 90°C, and add Ferric sulfate and barium sulfide were stirred for 1.5h and then filtered to obtain filtrate A. Added ferric sulfate in step a, ferric sulfate and the potassium ion in the manganese sulfate aqueous solution generate jarosite precipitation and remove the impurity potassium in the manganese sulfate aqueous solution, and the sodium ions in the ferric sulfate and the manganese sulfate aqueous solution generate yellow sodium iron vanadium Precipitate and remove the impurity sodium in the manganese sulfate aqueous solution; Added...

Embodiment 2

[0037] The present embodiment provides a kind of production method of battery grade high-purity manganese sulfate, comprises the following steps:

[0038] a. Dissolve the ordinary manganese sulfate particles containing impurities in the manganese sulfate compound solution from the cheap manganese sulfate factory, adjust the manganese sulfate aqueous solution with a concentration of 350g / L, adjust the pH value to 1.5, heat the solution to above 90°C, and add Ferric sulfate and barium sulfide were stirred for 1.5h and then filtered to obtain filtrate A. Added ferric sulfate in step a, ferric sulfate and the potassium ion in the manganese sulfate aqueous solution generate jarosite precipitation and remove the impurity potassium in the manganese sulfate aqueous solution, and the sodium ions in the ferric sulfate and the manganese sulfate aqueous solution generate yellow sodium iron vanadium Precipitate and remove the impurity sodium in the manganese sulfate aqueous solution; Added...

Embodiment 3

[0046] The present embodiment provides a kind of production method of battery grade high-purity manganese sulfate, comprises the following steps:

[0047] a. Dissolve the ordinary manganese sulfate particles containing impurities in the manganese sulfate compound solution from the cheap manganese sulfate factory, adjust the manganese sulfate aqueous solution with a concentration of 400g / L, adjust the pH value to 1.5, heat the solution to above 90°C, and add Ferric sulfate and barium sulfide were stirred for 1.5h and then filtered to obtain filtrate A. Added ferric sulfate in step a, ferric sulfate and the potassium ion in the manganese sulfate aqueous solution generate jarosite precipitation and remove the impurity potassium in the manganese sulfate aqueous solution, and the sodium ions in the ferric sulfate and the manganese sulfate aqueous solution generate yellow sodium iron vanadium Precipitate and remove the impurity sodium in the manganese sulfate aqueous solution; Added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com