Two ore combined process for treatment of laterite nickel ore and pyrolusite

A technology of lateritic nickel ore and combined method, which is applied in the field of metal mineral smelting, can solve the problems of environmental pollution, dust pollution, large coal consumption, etc., and achieve the effects of saving production costs, improving production efficiency, and improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

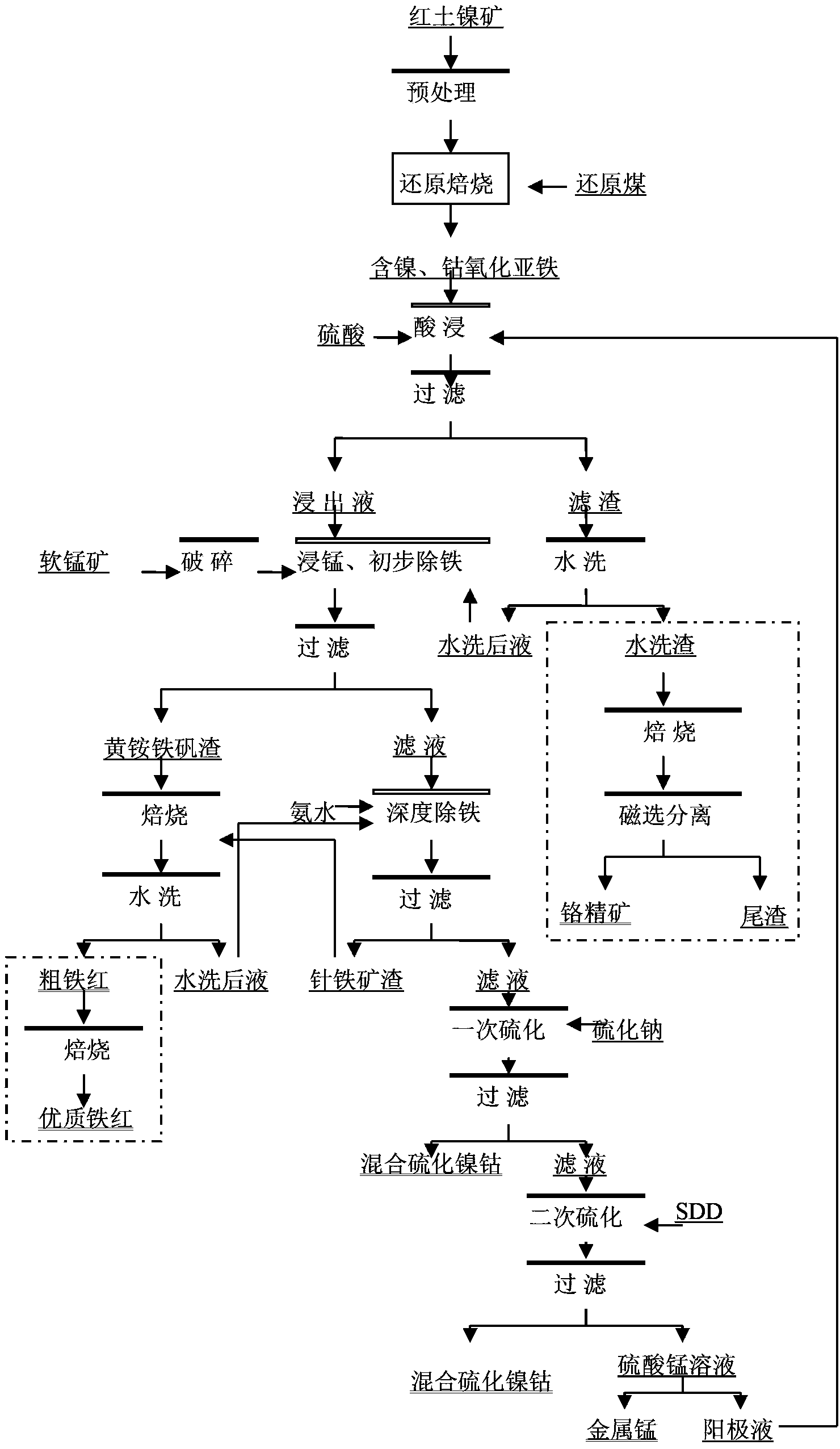

Method used

Image

Examples

Embodiment Construction

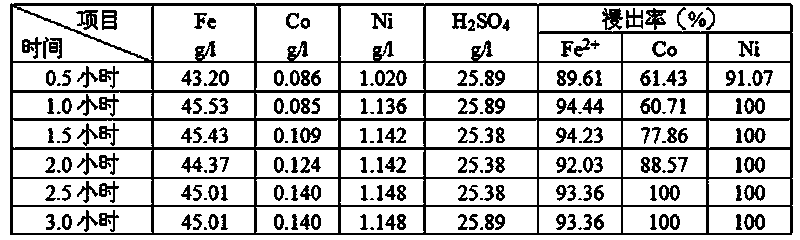

[0047] The Philippine laterite nickel ore and Gabon pyrolusite were used as raw materials, and the contents (mass fraction) of the main chemical components are shown in Table 1.

[0048] Table 1 Contents of main chemical components of Philippine laterite nickel ore and Gabon pyrolusite (%)

[0049]

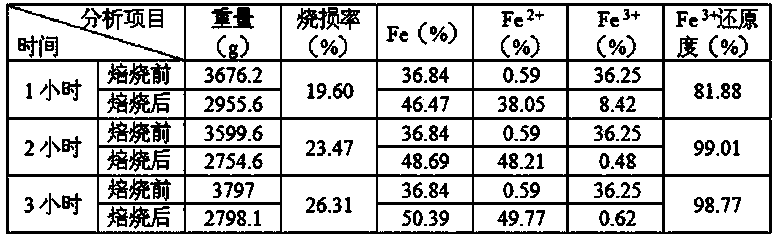

[0050] 1. Preparation of ferrous oxide powder containing nickel and cobalt by fire method

[0051] The raw materials (including laterite nickel ore and reduced coal) are placed in an electric heating constant temperature blast drying oven and dried at a temperature of 105°C. Among them, laterite nickel ore requires H 2 O≤10%, the reduced coal is baked to constant weight. According to a certain ratio (laterite nickel ore: coal = 100:16), the baked raw materials are fully mixed and set aside. A small pulverizer is used to grind the mixture to a certain particle size, and the passing rate under a 100-mesh sieve is required to be ≥95%.

[0052] The ground raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com