Resource utilization method for zinc hydrometallurgy jarosite residue and sewage treatment sludge

A technology of hydrometallurgy and sewage treatment, which is applied in the field of harmless treatment, disposal and resource utilization of solid waste in environmental engineering, can solve the problems of environmental pollution and low resource utilization rate, and achieve significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

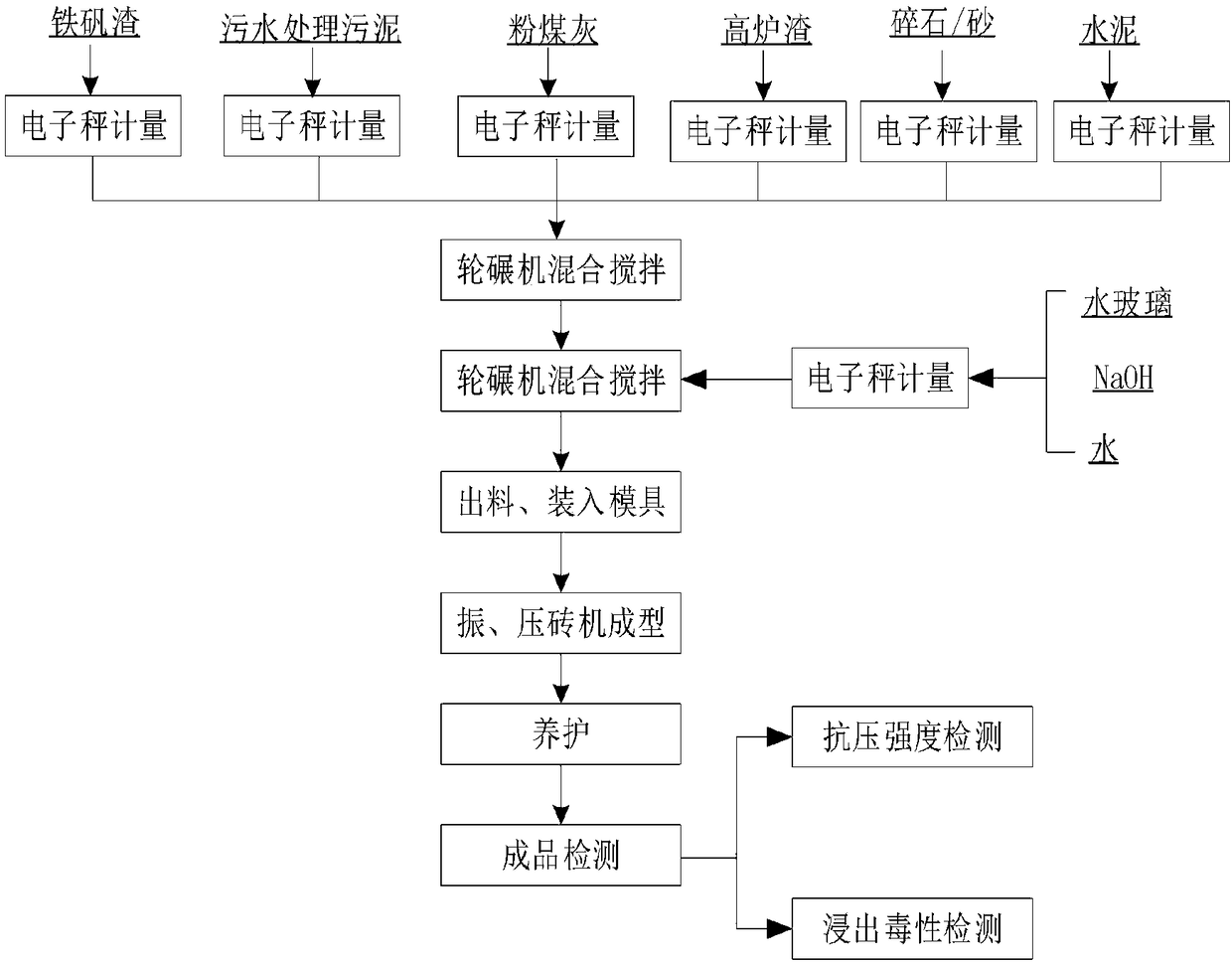

[0040] In order to further describe the present invention, a resource utilization method of the zinc-ferrosite slag and sewage treatment sludge of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0041]Examples The zinc hydrometallurgy slag and sewage treatment sludge treated in the embodiment come from a hydrometallurgy zinc smelting plant of a certain non-ferrous metal group. In the process of hydrometallurgy, the smelter adopts the process of "burning-leaching-purification-electrodeposition". The leaching process of the hydrogalvanizing plant system produces a large amount of jarosite slag, with an annual slag amount of 40,000t, and contains A small amount of heavy metals, such as Zn, Cu, Cd, Pb, As, etc., are hazardous wastes. The average daily sludge production in the zinc system sewage treatment process of the smelter is 28 tons, and the annual sewage treatment sludge production is about 9,240 tons.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com