Separation and extraction method for nickel and cobalt in low-grade sulfide mineral bioleaching agent through synergistic extraction

A technology for bioleaching and sulfide ore, applied in the direction of improving process efficiency, can solve the problems of entraining loss of valuable metal nickel and cobalt, increasing the pH value adjustment process before and after extraction, increasing the loss of valuable metal nickel and cobalt, etc., to achieve huge economic Economic and environmental benefits, the effect of reducing nickel-cobalt entrainment losses, reducing neutralization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

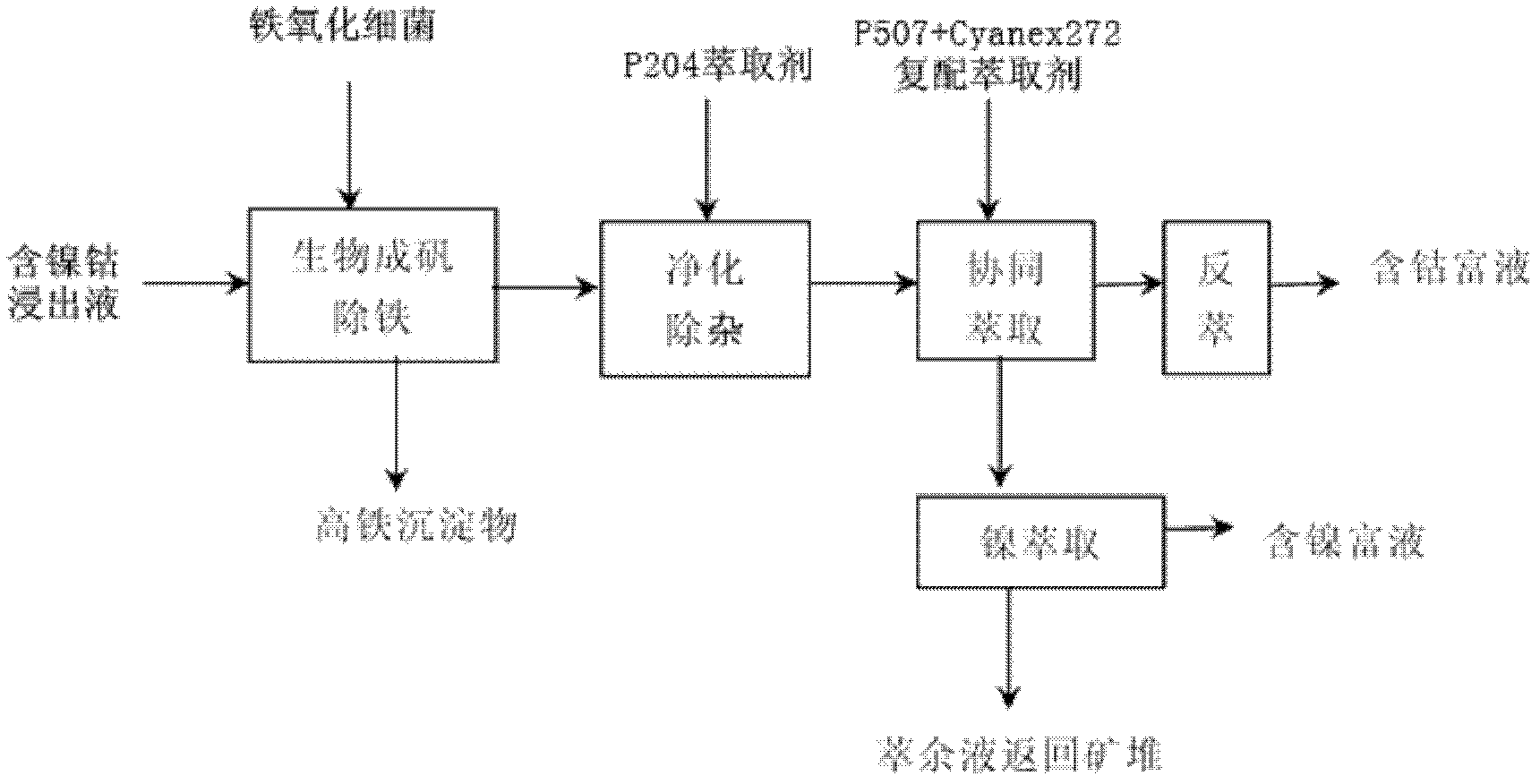

Method used

Image

Examples

Embodiment 1

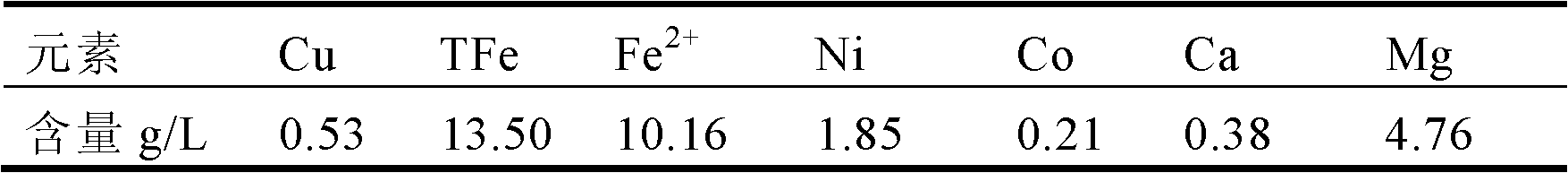

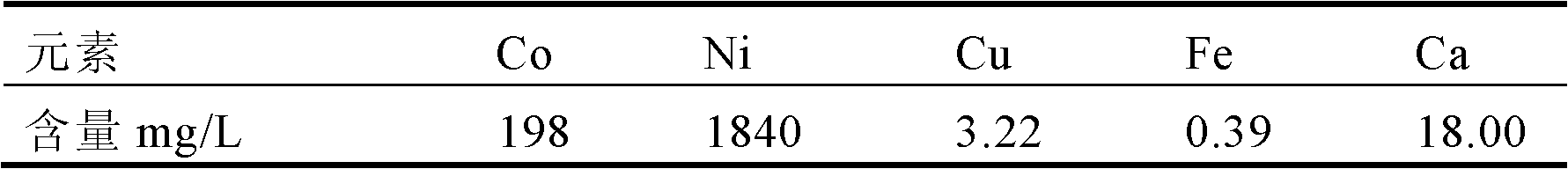

[0020] Since the Jilin Baishan nickel-cobalt ore is a low-grade complex and refractory sulfide ore, the bioleaching solution obtained by bioheap leaching contains low nickel and cobalt metals, and due to the recycling of the raffinate, the impurity ions continue to accumulate, so that the iron and calcium in the leaching solution The concentration of impurities such as magnesium is high, and the composition of the complex nickel-cobalt bioleaching solution is shown in Table 1. Excessively high concentration of impurity ions in the leaching solution will seriously reduce the extraction efficiency of nickel-cobalt. In addition, since the pH of the bioheap leaching process is around 1.8-2.0, and the conventional iron vitriol precipitation and nickel-cobalt extraction need to be under the condition of pH 3.5-4.0, therefore, it is necessary to adjust the pH value during precipitation and iron removal, which will cause nickel Cobalt entrainment loss, therefore, the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com