Silicon carbide micro-powder iron removal device for semiconductor

A silicon carbide micropowder and semiconductor technology, applied in solid separation, chemical instruments and methods, magnetic separation, etc., can solve the problems of increasing the production cost of silicon carbide powder, failing to meet the use requirements, and inconvenient cleaning of iron-containing substances. Simple and reasonable structure, high practical value, easy inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

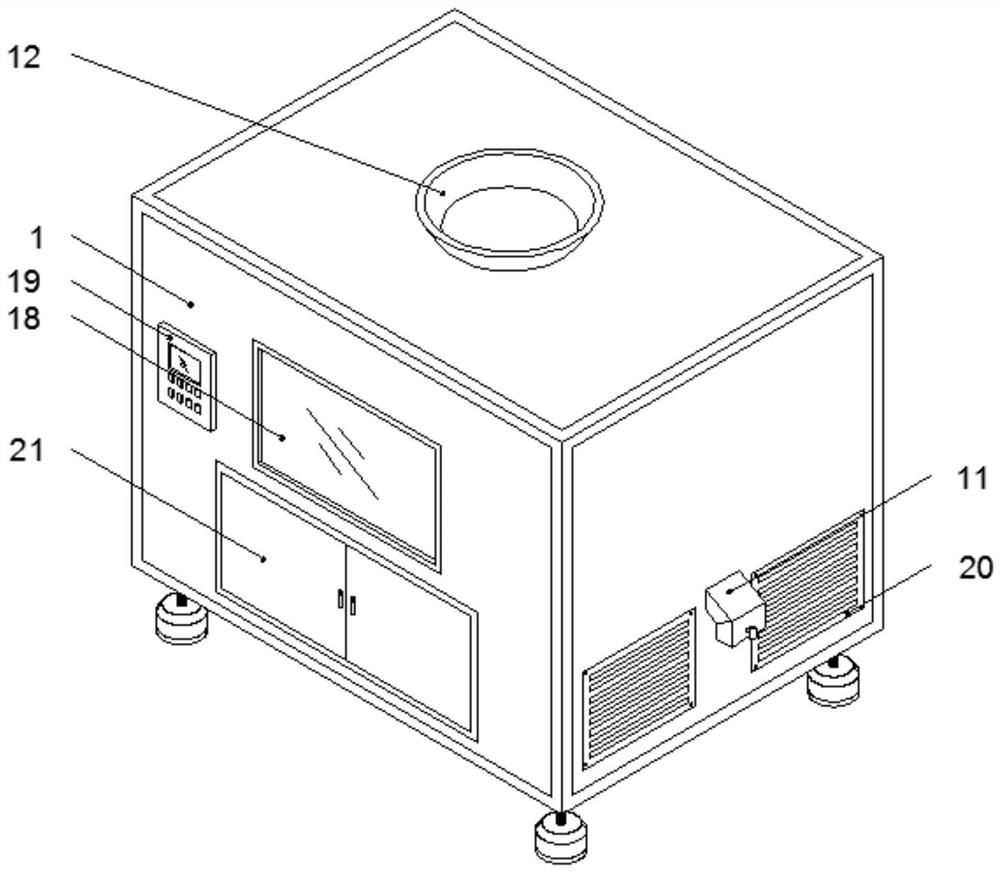

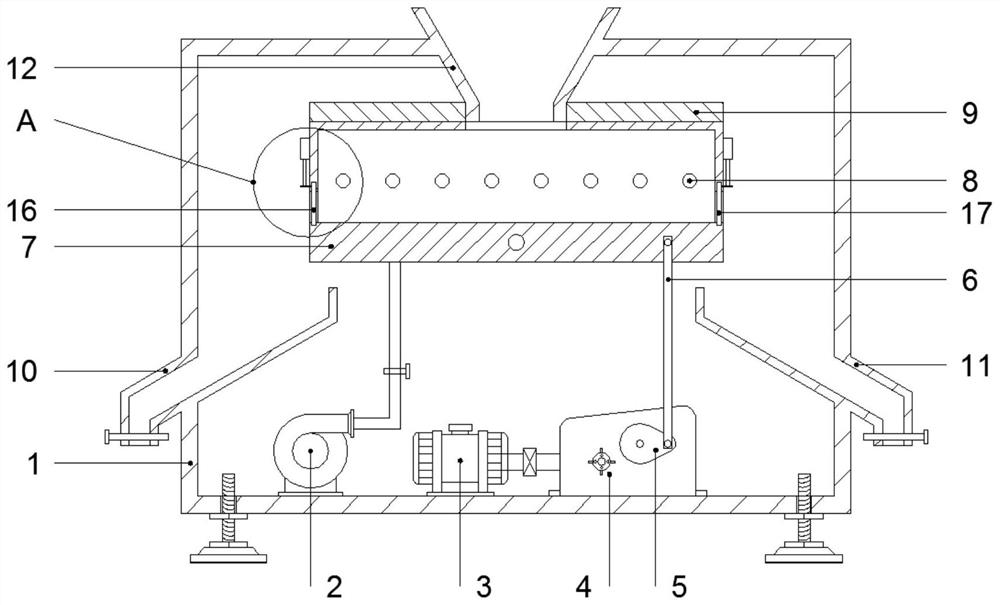

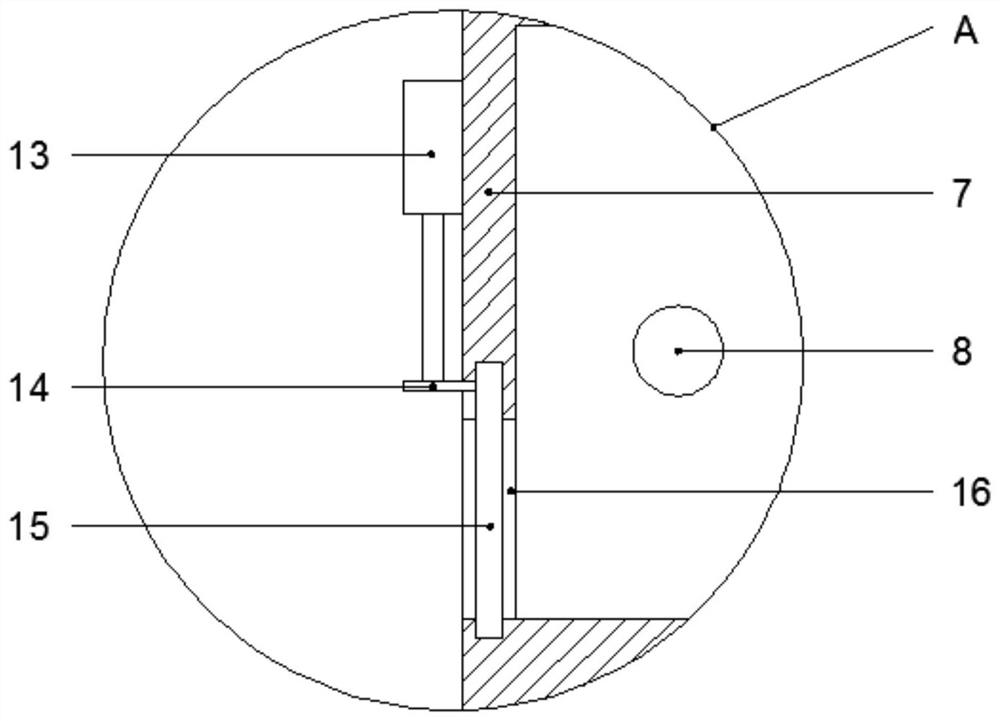

[0020] Example: such as Figure 1-3 As shown, a silicon carbide micropowder iron removal device for semiconductors is invented, which includes a main box body 1, an air pump 2 is fixedly installed on one side of the main box body 1, and a motor is fixedly installed on the side close to the air pump 2 inside the main box body 1. 3. The main box 1 is fixedly installed with a reducer 4 on the other side close to the motor 3, and the input shaft of the reducer 4 is connected to the motor 3 through a coupling, and the output shaft of the reducer 4 is fixedly installed with a cam 5 , the other end of the cam 5 is fixedly installed with a connecting rod 6, and the other end of the connecting rod 6 is fixedly installed with a screening box 7, and the inner side wall of the screening box 7 is provided with an air blowing hole 8, and the air blowing hole 8 passes through the pipeline and the air pump 2 are connected to each other, an electromagnet 9 is fixedly installed on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com