Method for recycling silver from jarosite residue

A recovery method and technology of jarosite slag, which is applied in the field of metallurgy, can solve the problems not involved in the extraction of silver from the jarosite slag, and achieve the effects of simple process and required equipment, convenient operation, and reduced silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix yellow ammonium iron vanadium slag with coal powder with a particle size of 74μm-3mm and lime with a particle size of 74μm-3mm with a grinder and press the balls to obtain mixed spheres with a diameter of less than 5mm, and then put the mixed spheres into a corundum crucible and refill Put it into a vacuum distillation furnace, keep it at 1100°C for 6 hours with a vacuum degree of 20 Pa, break the vacuum when the temperature in the furnace is lower than 100°C after the heat preservation is over, take it out of the vacuum distillation furnace to separate the silver and the reduced slag; among them, the added coal The ratio of the molar amount of powder, the molar amount of lime to the molar amount of silver in the yellow ammonium iron vanadium slag is 1:2:2.

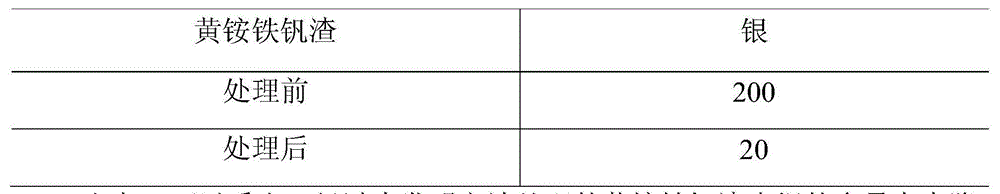

[0020] The silver before and after the treatment of the yellow ammonium iron vanadium slag of the present embodiment is carried out component analysis (composition content is in mass percentage), and its result ...

Embodiment 2

[0025] Mix jarosite slag with coal powder with a particle size of 74μm-3mm and limestone with a particle size of 3μm-50mm with an extruder and press balls to obtain mixed spheres with a diameter of less than 100mm, and then put the mixed spheres into a corundum crucible Then put it into a vacuum distillation furnace, keep it at 1200°C for 1 hour with a vacuum degree of 15Pa, and break the vacuum when the temperature in the furnace is lower than 100°C after the heat preservation is completed, and take out the vacuum distillation furnace to separate the silver and the reduced slag; among them, the The ratio of the molar amount of added coal powder, the molar amount of limestone to the molar amount of silver in the jarosite slag is 1:2:0.1.

Embodiment 3

[0027] Mix yellow ammonium iron vanadium slag with coal powder with a particle size of 74μm-3mm and dolomite with a particle size of 1mm-10mm with a cylinder mixer and press the ball to obtain a mixed sphere with a diameter of less than 50mm, and then put the mixed sphere into the corundum Then put the crucible into a vacuum distillation furnace, keep the temperature at 1100°C for 4 hours with a vacuum degree of 18 Pa, and break the vacuum when the temperature in the furnace is lower than 100°C after the heat preservation, and take out the vacuum distillation furnace to separate the silver and the reduced slag; among them, The ratio of the molar amount of the added coal powder, the molar amount of dolomite to the molar amount of silver in the yellow ammonium iron vanadium slag is 1:10:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com