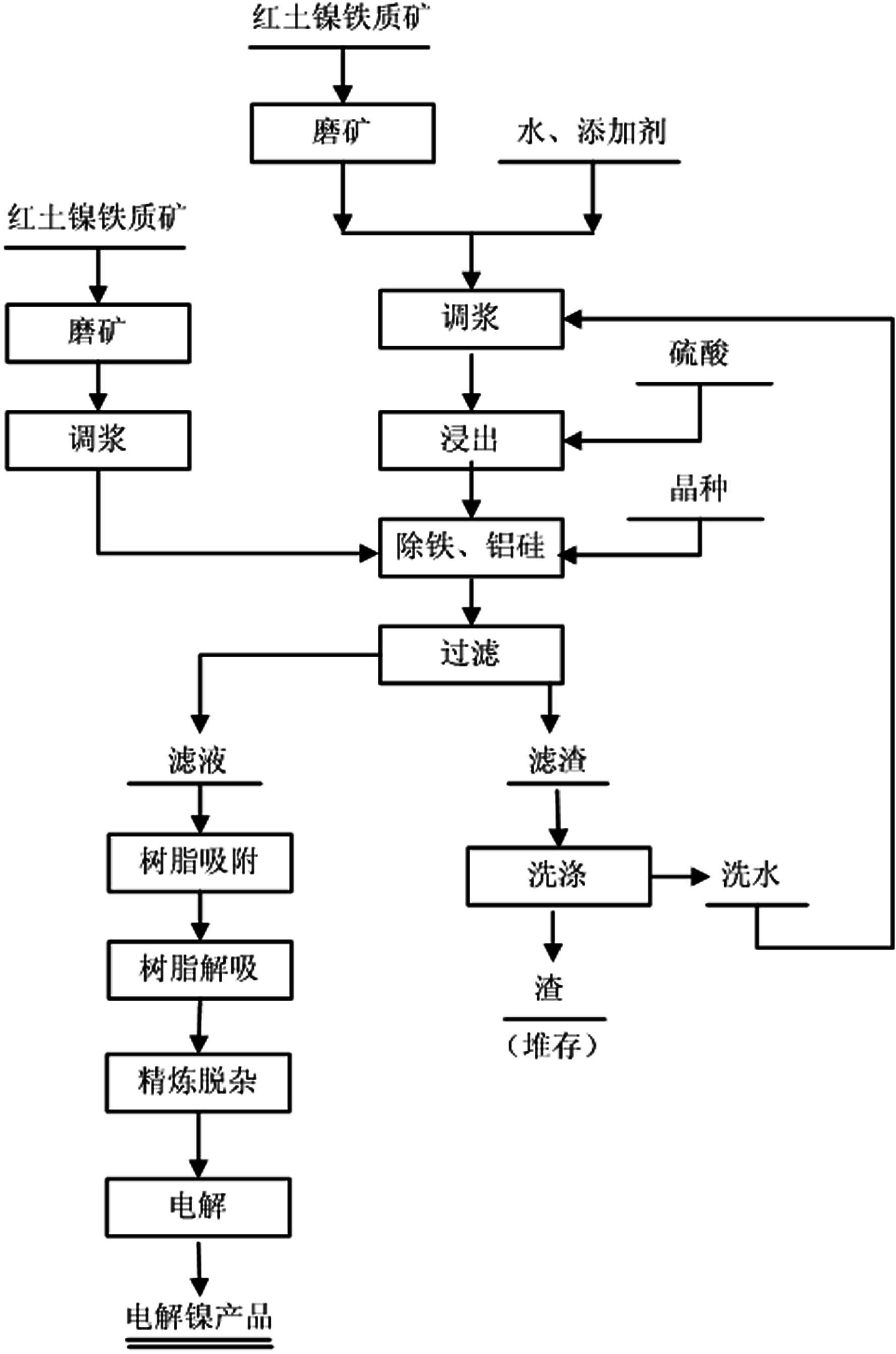

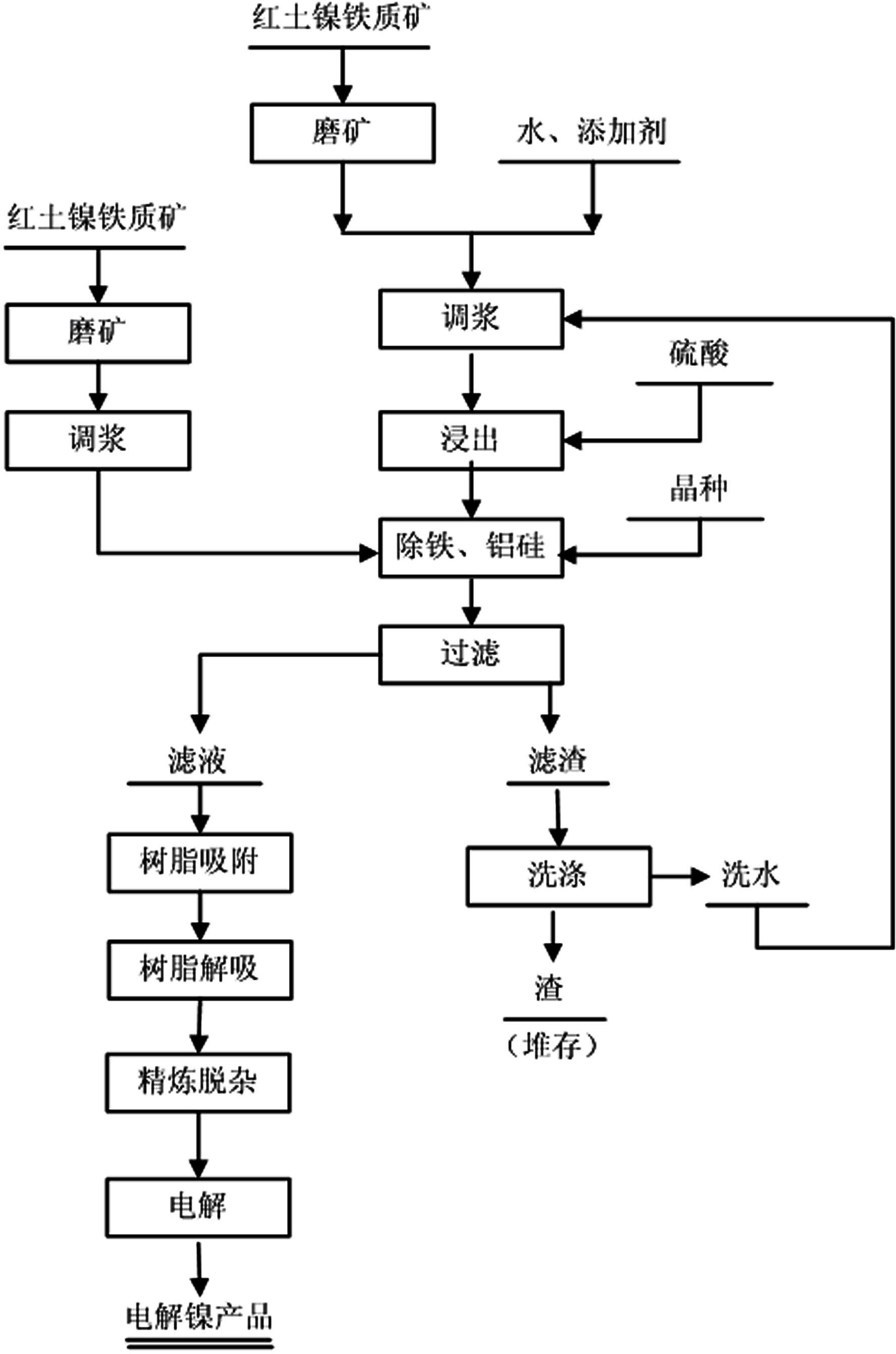

A kind of method of direct electrolysis of sulfuric acid leaching of laterite nickel ore

A laterite nickel ore and leaching technology, which is applied to the improvement of process efficiency, photography technology, instruments and other directions, can solve the problems of large amount of magnesium-containing wastewater, low recovery rate, difficult treatment, etc., and achieves reduction of acid consumption and filtration energy. The effect of consumption and quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Take 200g of lateritic nickel-iron ore (containing 0.8-1.8% nickel, 15-30% iron, and magnesium <15%) and grind it to -100 mesh, and add water to prepare iron slurry with a solid content of 30%.

[0036] Take 200g of laterite nickel-magnesium ore (containing 0.8-1.8% nickel, iron <15%, 10-30% magnesium) and grind it to -100 mesh, add water to prepare magnesia slurry with a solid content of 30%.

[0037] Slowly add 120ml of sulfuric acid into the iron ore slurry, stir under normal pressure, and carry out sulfuric acid leaching of the iron ore for 4 hours.

[0038] In the leached acid leaching pulp, slowly add the prepared magnesia pulp, add 20g of sodium sulfate, stir under normal pressure, monitor the pH value until pH=3.0, stop adding magnesia pulp, continue stirring for 3 hours, and complete the precipitation of iron vanadium. Slowly add calcium hydroxide solution, monitor the pH value until pH = 6.0, complete the precipitation of aluminum and silicon afte...

Embodiment 2

[0042] Example 2: Take 200g of lateritic nickel-iron ore (containing 0.8-1.8% nickel, 15-30% iron, and magnesium <15%) and grind it to -160 mesh, and add water to prepare iron slurry with a solid content of 35%.

[0043] Take 200g of laterite nickel-magnesium ore (containing 0.8-1.8% nickel, iron <15%, 10-30% magnesium) and grind it to -100 mesh, add water to prepare magnesia slurry with a solid content of 30%.

[0044] Slowly add 110ml of sulfuric acid into the iron ore slurry, stir under normal pressure, and carry out sulfuric acid leaching of the iron ore for 4 hours.

[0045] In the leached acid leaching pulp, slowly add the prepared magnesia pulp, add 20g of sodium sulfate, stir under normal pressure, monitor the pH value until pH=3.0, stop adding magnesia pulp, continue stirring for 3 hours, and complete the precipitation of iron vanadium. Slowly add calcium hydroxide solution, monitor the pH value until pH = 6.0, complete the precipitation of aluminum and silicon aft...

Embodiment 3

[0049] Example 3: Take lateritic nickel-iron ore (containing 0.8-1.8% nickel, 15-30% iron, magnesium <15%) 200g and grind it to -200 mesh, add water to prepare iron slurry with a solid content of 40%.

[0050] Take 200g of laterite nickel-magnesium ore (containing 0.8-1.8% nickel, iron <15%, 10-30% magnesium) and grind it to -100 mesh, add water to prepare magnesia slurry with a solid content of 30%.

[0051] Slowly add 95ml of sulfuric acid into the iron ore slurry, stir under normal pressure, and carry out sulfuric acid leaching of the iron ore for 4 hours.

[0052] In the leached acid leaching pulp, slowly add the prepared magnesia pulp, add 20g of sodium sulfate, stir under normal pressure, monitor the pH value until pH=3.0, stop adding magnesia pulp, continue stirring for 3 hours, and complete the precipitation of iron vanadium. Slowly add calcium hydroxide solution, monitor the pH value until pH = 6.0, complete the precipitation of aluminum and silicon after no change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com