Zinc-nickel alloy electroplating system

A zinc-nickel alloy and coating technology, which is applied in the field of electroplating compositions for electroplating zinc-nickel alloys, can solve problems such as difficult removal of metal ions, complexation of metal ions, and wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

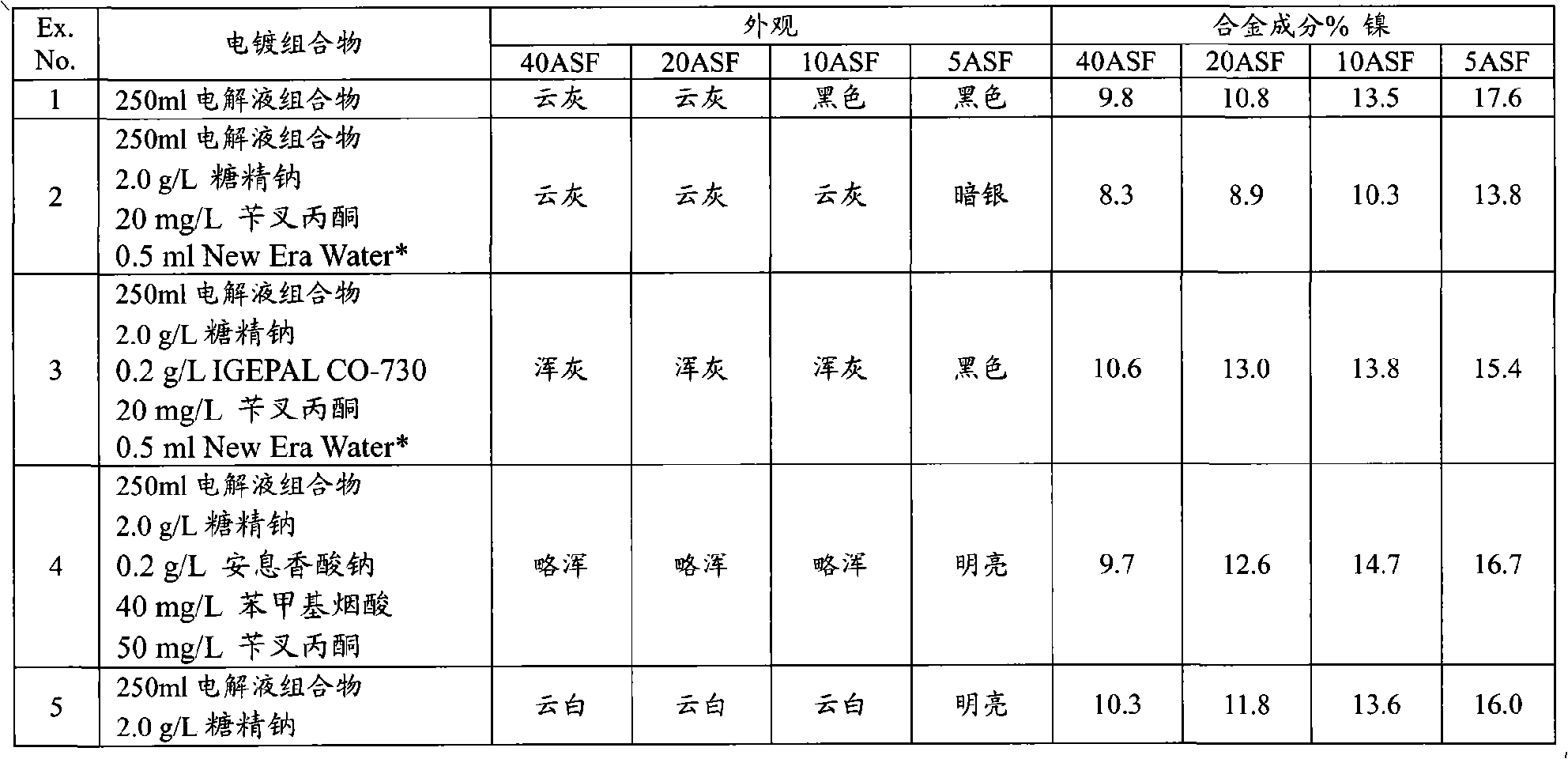

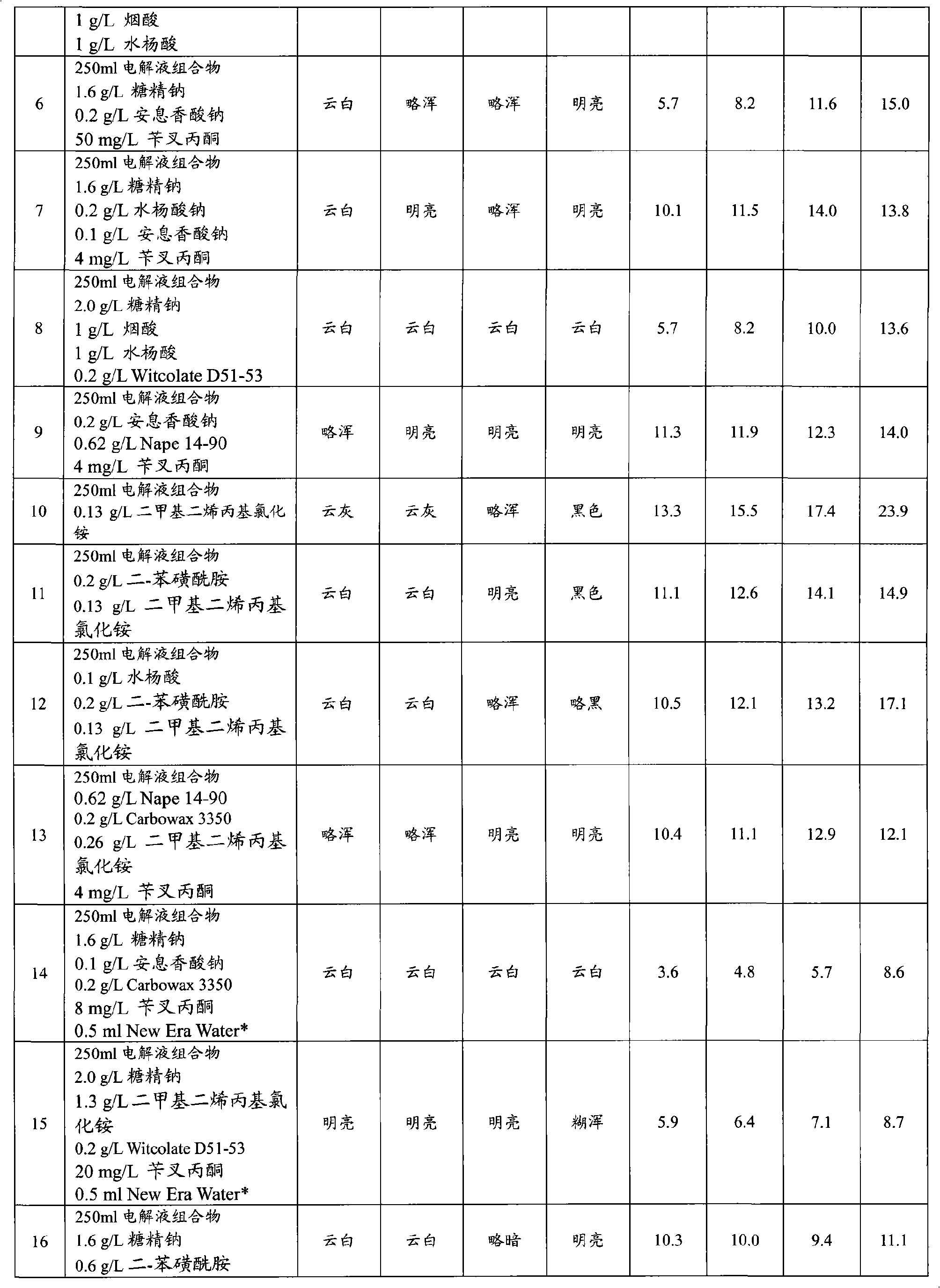

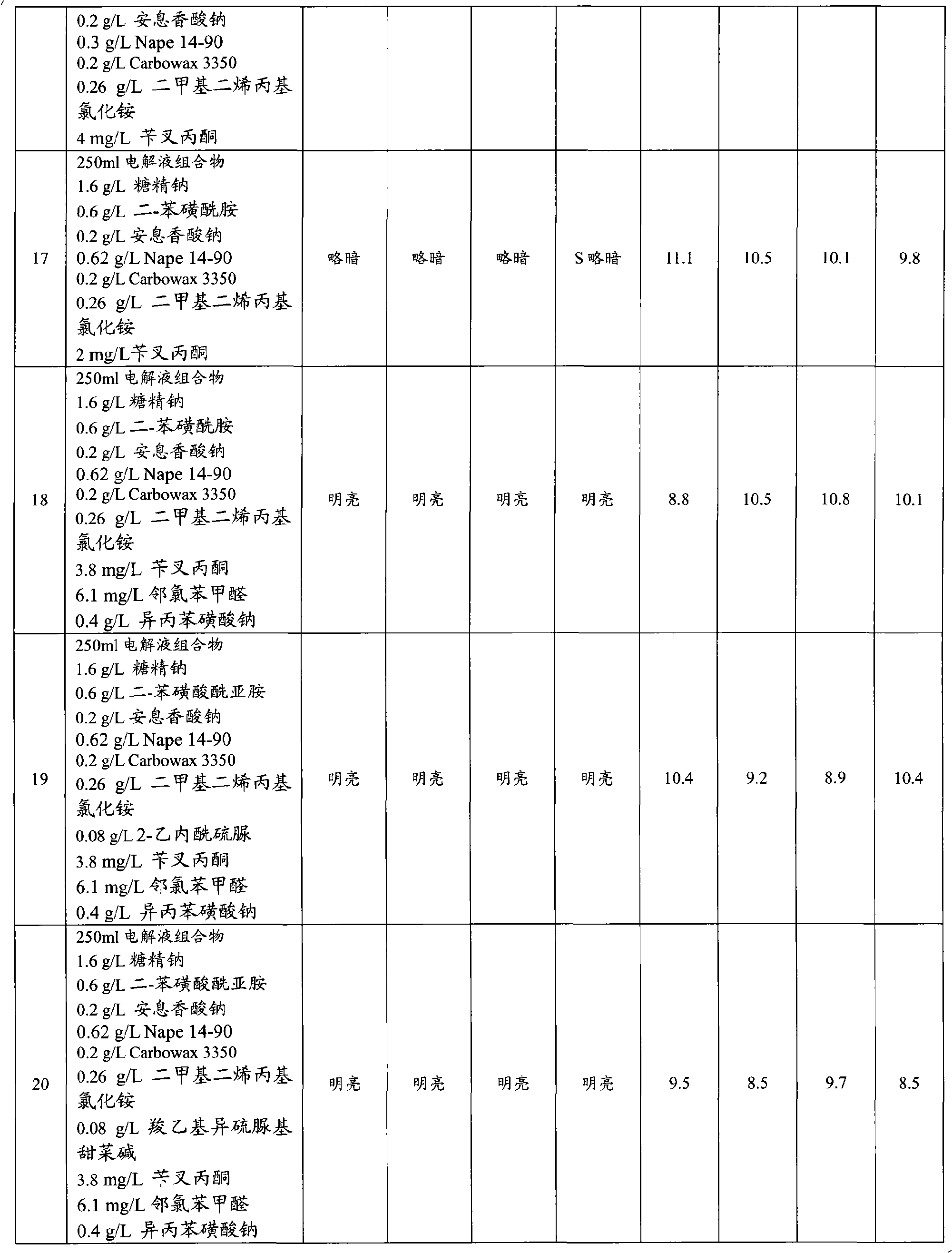

Examples

Embodiment Construction

[0013] The zinc-nickel alloy electroplating composition of the present invention will be described in detail below in combination with specific embodiments. Of course, the present invention can also have many other implementations, so it is not limited to the implementations given in this application, and these implementations are only used to reveal and disclose the present invention to meet legal requirements. In addition, the singular forms of "a", "an" and "the" in the specification and claims of the present invention may also have plural meanings according to different situations, unless otherwise specified.

[0014] The invention provides an electroplating composition that can be used for electroplating a zinc-nickel alloy on a substrate. The advantage of the electroplating composition of the invention is that it has good versatility. For example, electroplating compositions can be tailored to achieve good physical and chemical properties (eg, corrosion protection of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com