Preparation method of lithium ion battery positive material nickel cobalt aluminum

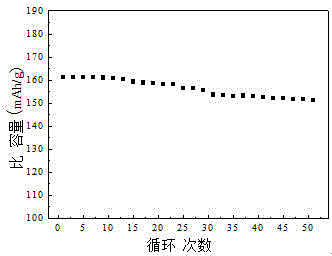

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of affecting the electrochemical properties of materials, different electrochemical properties of materials, mixing and other issues, and achieve good cycle stability and high reversibility. Specific capacity, the effect of improving electrochemical performance

Inactive Publication Date: 2015-03-25

HARBIN INST OF TECH AT WEIHAI

View PDF3 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Nickel-cobalt-aluminum hydroxide, mainly nickel hydroxide, decomposes above 230°C to form NiO. When the temperature reaches 400°C, part of NiO absorbs air and oxidizes into Ni 2 o 3 , and finally when the temperature is higher than 600℃, the Ni 2 o 3 Reduced NiO with low activity; in addition, if the content of divalent nickel in nickel-cobalt-aluminum oxide is too high, the subsequent sintering process cannot be completely oxidized to trivalent nickel, and the radius of divalent nickel is very close to that of lithium ions, which is prone to mixing. , affecting the electrochemical performance of the material

Therefore, pre-sintering at different temperatures results in different Ni 2+ and Ni 3+ content of the precursor, the electrochemical performance of the final material is different

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

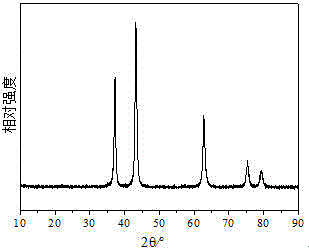

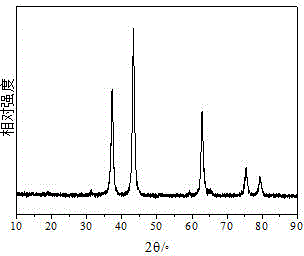

The invention discloses a preparation method of lithium ion battery positive material nickel cobalt aluminum. The preparation method comprises the following steps: mixing nickel, cobalt and aluminum salt solutions, mixing a precipitator, a complexing agent and the mixed solution of the nickel cobalt aluminum to obtain a mixed solution, adding the mixed solution into a reaction kettle to carry out co-precipitation reaction, adjusting the pH value of the system to 10 to 11 at the temperature of 40 to 60 DEG C, stirring at the speed of 500 to 1500 turns / minute, carrying out reaction for 10 to 30 hours, filtering, washing and drying to obtain a hydroxide precursor; pre-sintering the precursor at high temperature to obtain a nickel cobalt aluminum oxide, mixing the nickel cobalt aluminum oxide with a lithium source to obtain a mixture, sintering the mixture at high temperature under an oxygen atmosphere, and crushing and sieving to obtain the nickel cobalt aluminum powder. By calculating the pre-sintering loss rate of the precursor, the content of Ni<2+> and the content of Ni<3+> in the nickel cobalt aluminum oxide at different temperatures are analyzed by utilizing XPS, so that the nickel cobalt aluminum oxide with the highest content of Ni<3+> can be obtained, more nickel ions in the secondary sintering process can be promoted to be converted into Ni<3+>, the mixed arrangement of the Li<+> and the Ni<2+> can be reduced, and the electrochemical performance of the material can be improved.

Description

technical field [0001] The invention relates to the fields of energy storage materials and electrochemistry, in particular to a preparation method of nickel-cobalt-aluminum cathode material for lithium ion batteries. Background technique [0002] Since the Japanese SONY company first successfully developed and commercialized lithium-ion batteries in 1991, lithium-ion batteries have attracted more and more attention because of their light weight, small size, high specific energy, small self-discharge, and good cycle performance. With the characteristics of low pollution and no memory effect, it has become one of the most promising green secondary batteries in the 21st century. With the development of electrode materials, battery cathode materials with their own characteristics have emerged one after another, such as lithium cobalt oxide, lithium nickel oxide, lithium manganese oxide, lithium iron phosphate, and nickel-cobalt-manganese ternary materials. At present, lithium-i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/485H01M4/525

CPCH01M4/485H01M4/525Y02E60/10

Inventor 朱永明胡会利阮泽文滕祥国于元春

Owner HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com