Preparation method of wave absorbing material with nickel nanoparticles wrapped with porous carbon-loaded graphene

A graphene-coated, microwave-absorbing material technology, applied in nanotechnology, chemical instruments and methods, transportation and packaging, etc., can solve the problems of high cost, high cost of composite materials and difficulty in popularization and application, and achieve low cost and high microwave absorption performance, large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Prepare a nickel nitrate solution with a concentration of 0.05 mol / L, select 20 g of natural algae plants, and soak the algae in the prepared nickel nitrate solution for 24 hours. Wherein, the natural algae plant is laver.

[0025] Step 2: crush the soaked algae with a mixer, centrifuge and take the centrifuged product for freeze-drying, and after it is completely dry, pulverize and grind to obtain powder sample A.

[0026] Step 3: Weigh an appropriate amount of sample A, place it in a vacuum reaction furnace, and heat it at 200°C for 30 minutes to obtain sample B.

[0027] Step 4: Weigh an appropriate amount of sample B, place it in a vacuum reaction furnace, and heat it at 300°C for 30 minutes to obtain sample C.

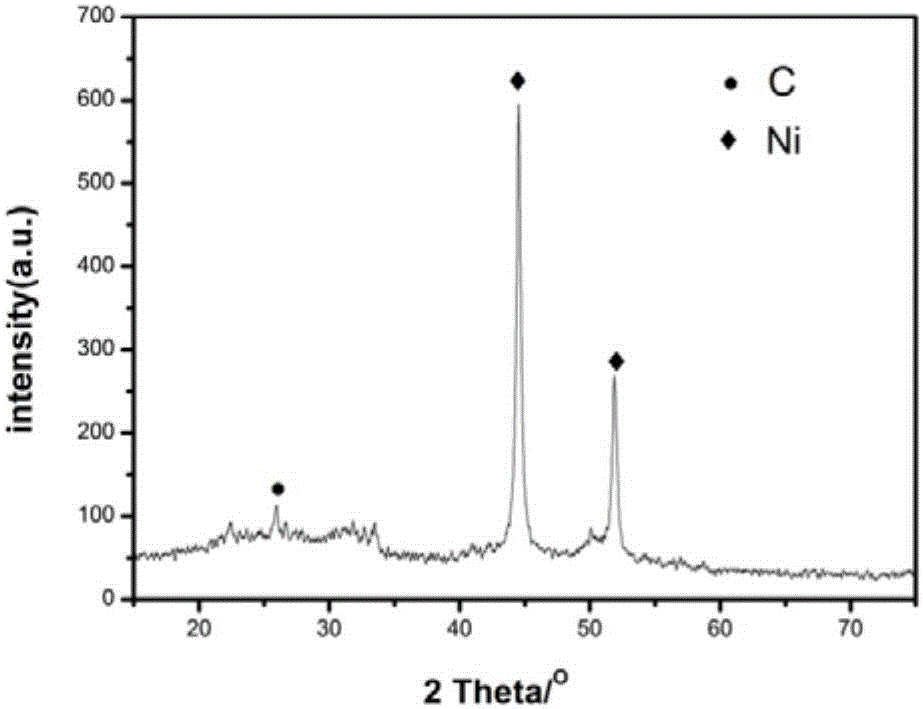

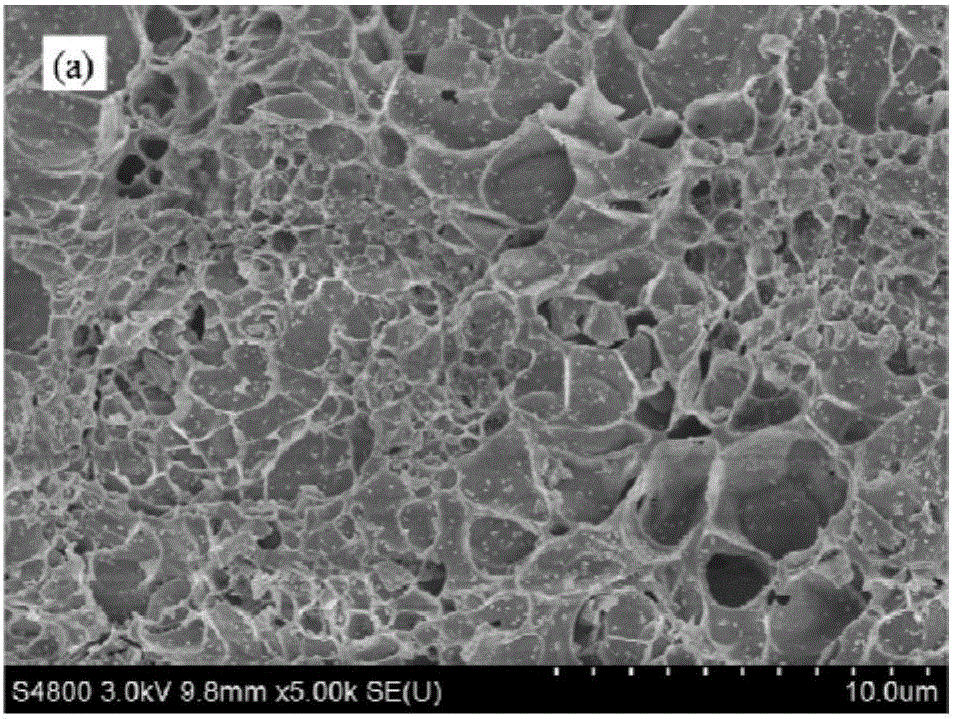

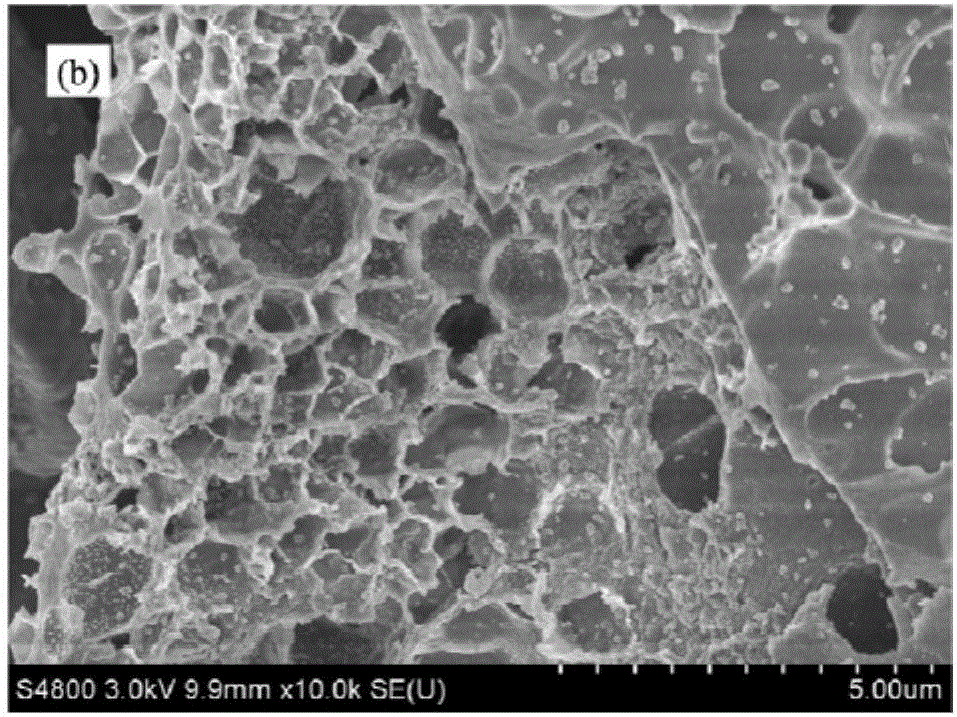

[0028] Step 5: Weigh an appropriate amount of sample C, place it in a high-temperature tube furnace, and heat it for 30 minutes at 500°C under an argon atmosphere to obtain a porous carbon-loaded graphene-coated nano-nickel particle absorbing mater...

Embodiment 2

[0031] Step 1: Prepare a nickel nitrate solution with a concentration of 0.05 mol / L, select 20 g of natural algae plants, and soak the algae in the prepared nickel nitrate solution for 24 hours. Among them, the natural algae plant is Porphyridium coccus.

[0032] Step 2: crush the soaked algae with a mixer, centrifuge and take the centrifuged product for freeze-drying, and after it is completely dry, pulverize and grind to obtain powder sample A.

[0033] Step 3: Weigh an appropriate amount of sample A, place it in a vacuum reaction furnace, and heat it at 200°C for 30 minutes to obtain sample B.

[0034] Step 4: Weigh an appropriate amount of sample B, place it in a vacuum reaction furnace, and heat it at 350°C for 30 minutes to obtain sample C.

[0035] Step 5: Weigh an appropriate amount of sample C, place it in a high-temperature tube furnace, and heat it for 30 minutes at 500°C under an argon atmosphere to obtain a porous carbon-supported graphene-coated nano-nickel part...

Embodiment 3

[0038] Step 1: Prepare a nickel nitrate solution with a concentration of 0.10 mol / L, select 20 g of natural algae plants, and soak the algae in the prepared nickel nitrate solution for 24 hours. Among them, the natural algae plant is Ulva.

[0039] Step 2: crush the soaked algae with a mixer, centrifuge and take the centrifuged product for freeze-drying, and after it is completely dry, pulverize and grind to obtain powder sample A.

[0040] Step 3: Weigh an appropriate amount of sample A, place it in a vacuum reaction furnace, and heat it at 250°C for 30 minutes to obtain sample B.

[0041] Step 4: Weigh an appropriate amount of sample B, place it in a vacuum reaction furnace, and heat it at 400°C for 30 minutes to obtain sample C.

[0042] Step 5: Weigh an appropriate amount of sample C, place it in a high-temperature tube furnace, and heat it for 30 minutes at 600°C under an argon atmosphere to obtain a porous carbon-supported graphene-coated nano-nickel particle absorbing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com