Pulse container formation method for high-capacity lead-acid battery

A lead-acid battery, internalized technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery charging/discharging, etc., to achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Taking the NM450 battery commonly used in electric locomotive railway batteries as an example, the specific implementation of the low-frequency positive pulse formation charging method of the present invention is further described.

[0028] Put 96 NM450 batteries assembled with green plates in the water tank, pour 1.23g / cm3 sulfuric acid, the amount of acid per cell is 7500ml, after 2 hours of acid filling, turn on the power and start to form. Pulse internalization proceeds in five phases:

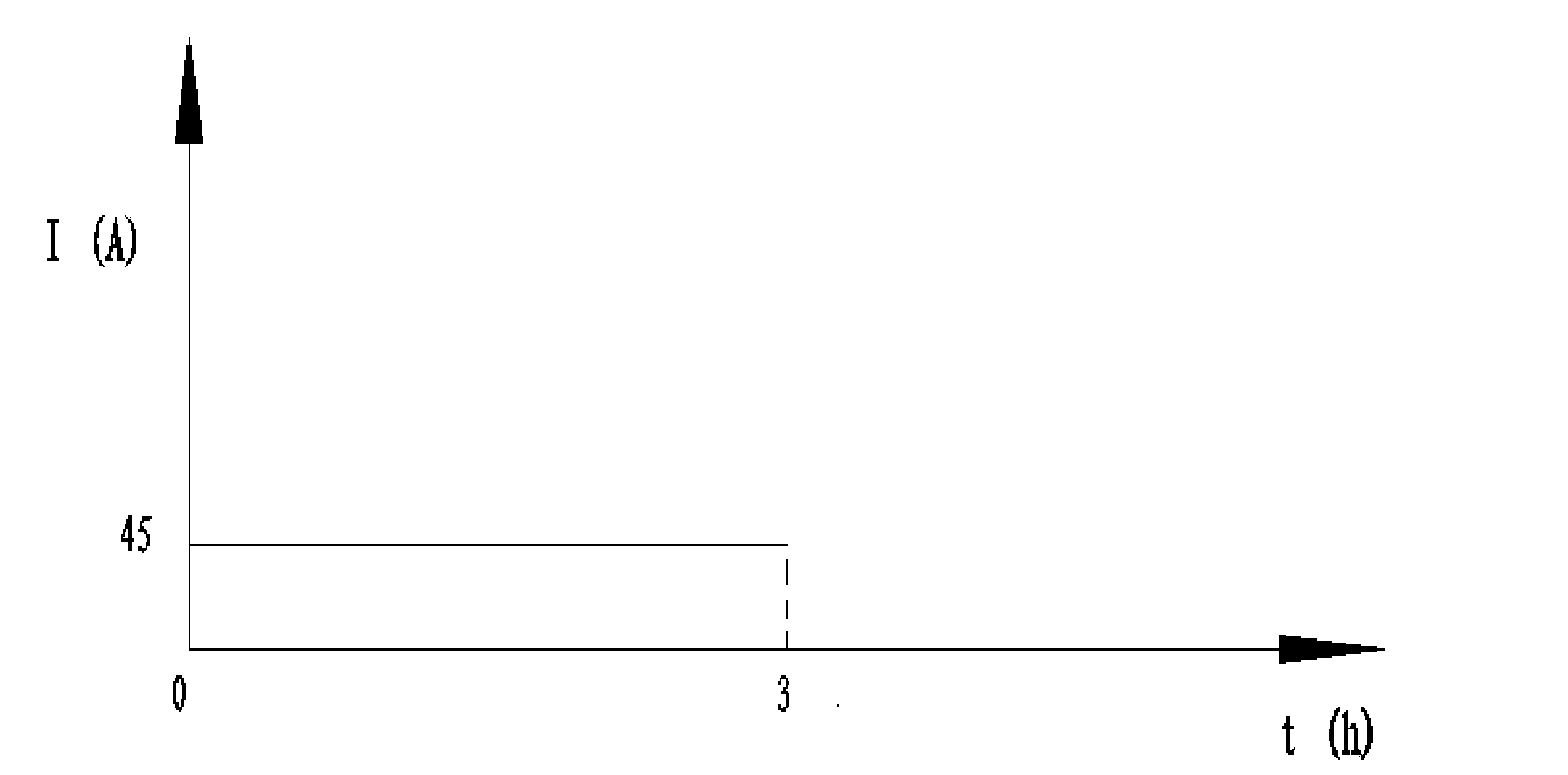

[0029] The first stage is the internalization into the boot stage, using 0.1C constant current charging for 3h.

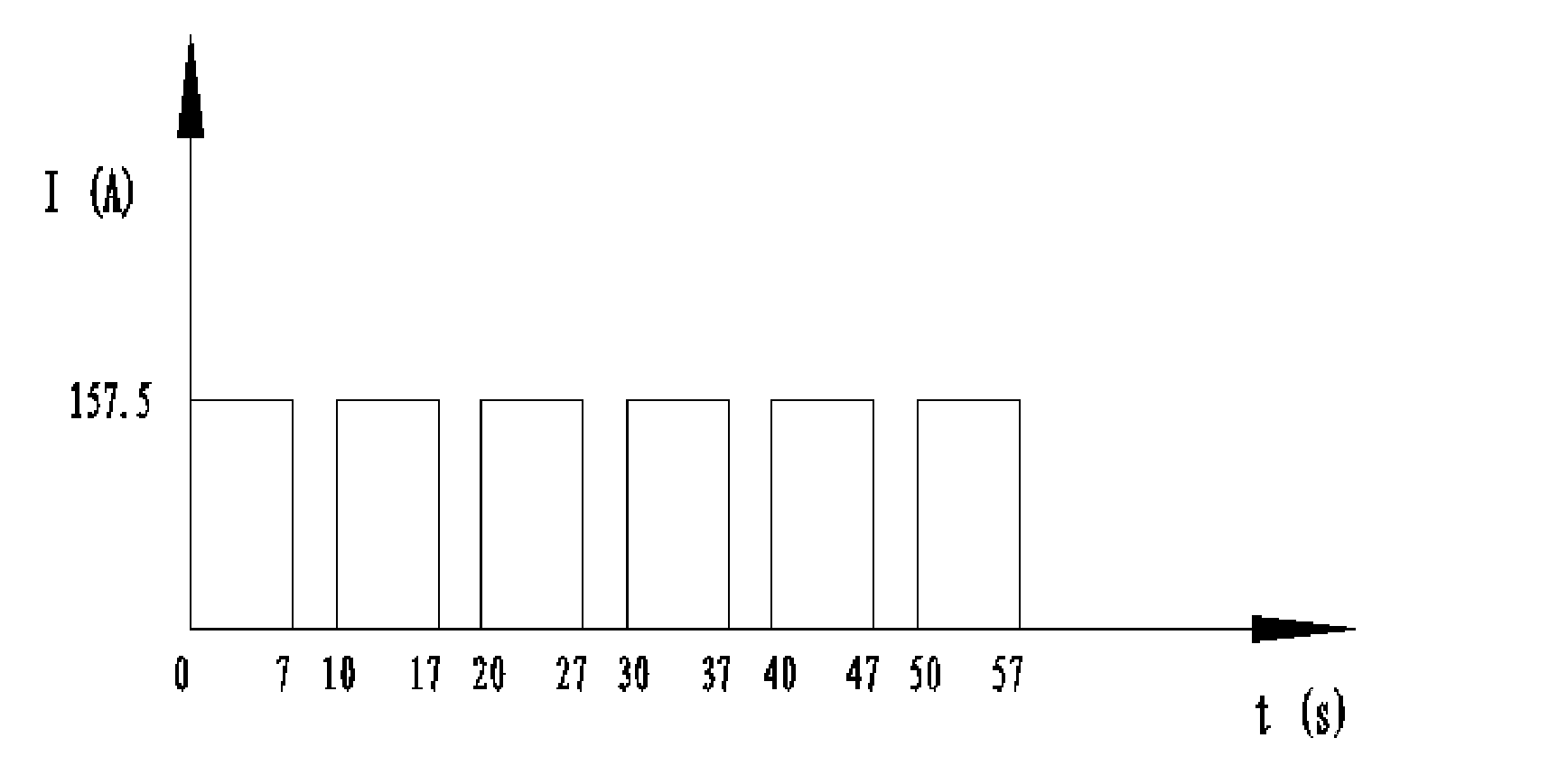

[0030] The second stage is low-frequency positive pulse formation, the pulse frequency is 0.1Hz, the amplitude of the positive pulse is 0.4C, the pulse time is 7s, and the intermittent time is 3s, for a total of 26h. Stand still for 20-30min, then discharge at 0.3C for 1h.

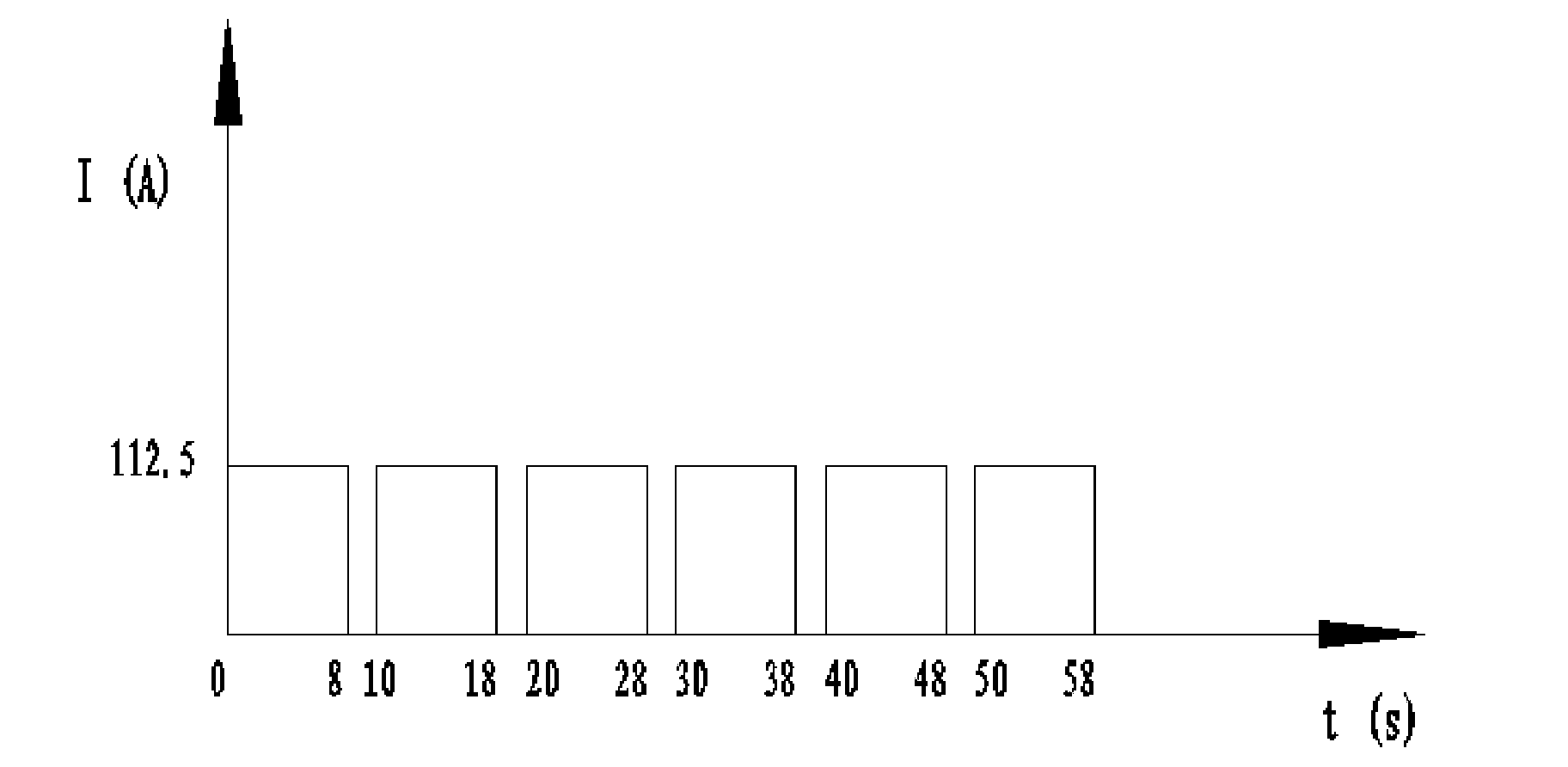

[0031] The third stage is low-frequency positive pulse formation, the pulse frequ...

Embodiment 2

[0043] Embodiment 2: In order to further illustrate the process of the present invention, exemplify below in conjunction with 2V170Ah:

[0044]

[0045] After testing, the performance of the battery has reached the national standard, which is 64.5 hours shorter than the ordinary internalization process.

Embodiment 3

[0046] Embodiment 3: In order to further illustrate the process of the present invention, illustrate below in conjunction with 2V800Ah:

[0047]

[0048] After testing, the performance of the battery has reached the national standard, which is 57.5 hours shorter than the ordinary internalization process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com