Roll-type reverse-osmosis membrane element with variable-thickness channel net

A technology of reverse osmosis membrane and thickness change, applied in reverse osmosis, semi-permeable membrane separation, membrane technology and other directions, can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

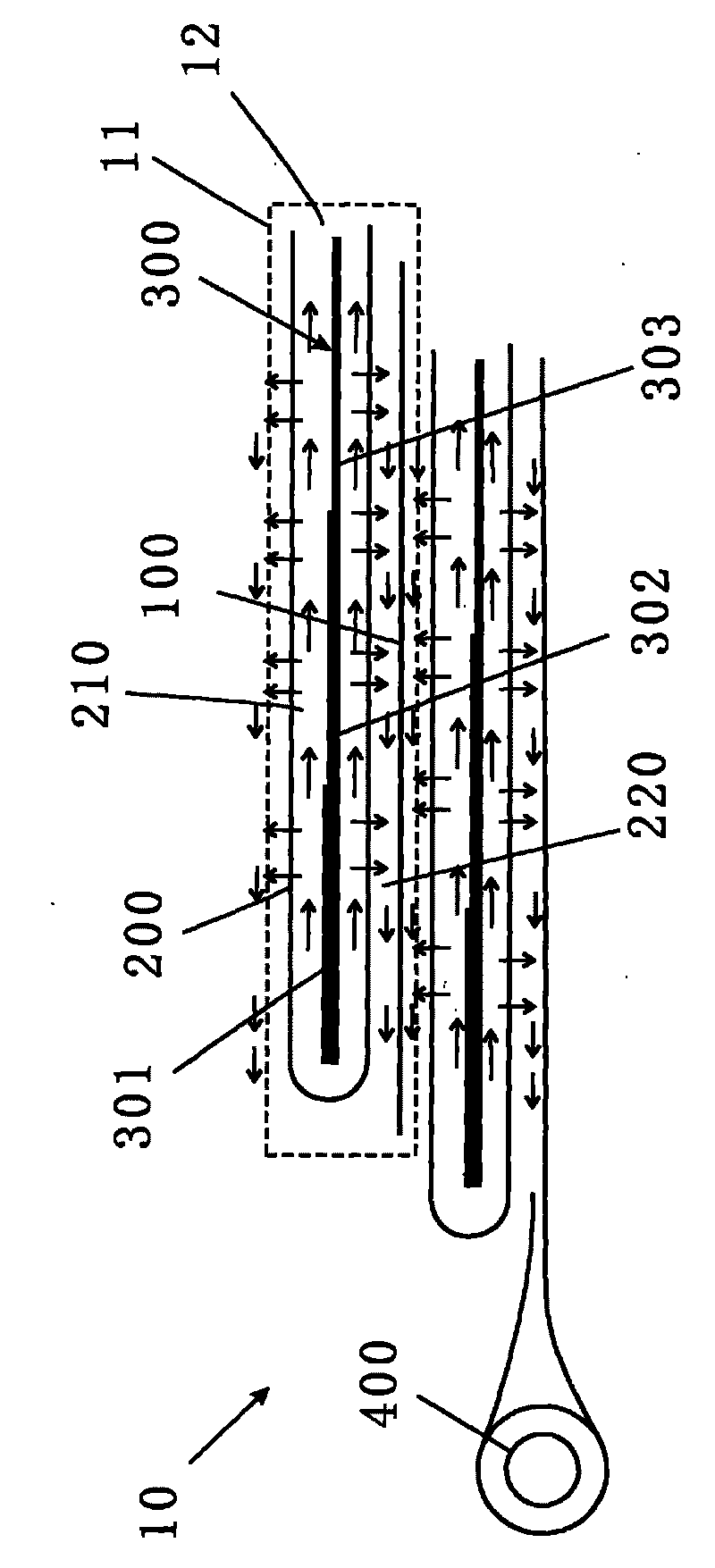

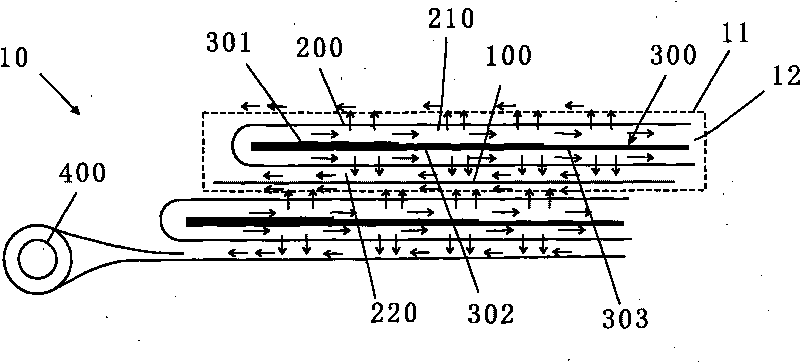

[0012] Such as figure 1 As shown, the roll-type reverse osmosis membrane element 10 of the present invention with a variable channel network thickness is composed of two sets of water purification membranes composed of pure water diversion net 100, reverse osmosis membrane 200, and water inlet diversion net 300. 11 is wound on the central water production pipe 400 to form.

[0013] Wherein, the reverse osmosis membrane 200 forms the water inlet flow channel 210 through folding the inner surface, and forms the water production flow channel 220 between the adjacent outer surfaces (the lower outer surface of the reverse osmosis membrane of the bottom water purification membrane group and the water purification of the top layer The upper and outer surfaces of the reverse osmosis membranes of the membrane group also form a water production flow channel after winding), the water inlet flow channel 300 is located in the water intake flow channel 210 , and the pure water flow guide ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com