Overstable three-electrode electron beam evaporation source

An electron beam evaporation, three-electrode technology, applied in vacuum evaporation coating, ion implantation coating, metal material coating process, etc., can solve the problems of complicated electron beam trajectory control method, easy pollution of evaporation materials, uneven heating, etc. , to increase the types of targets, improve the compatibility of the device, and prolong the life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

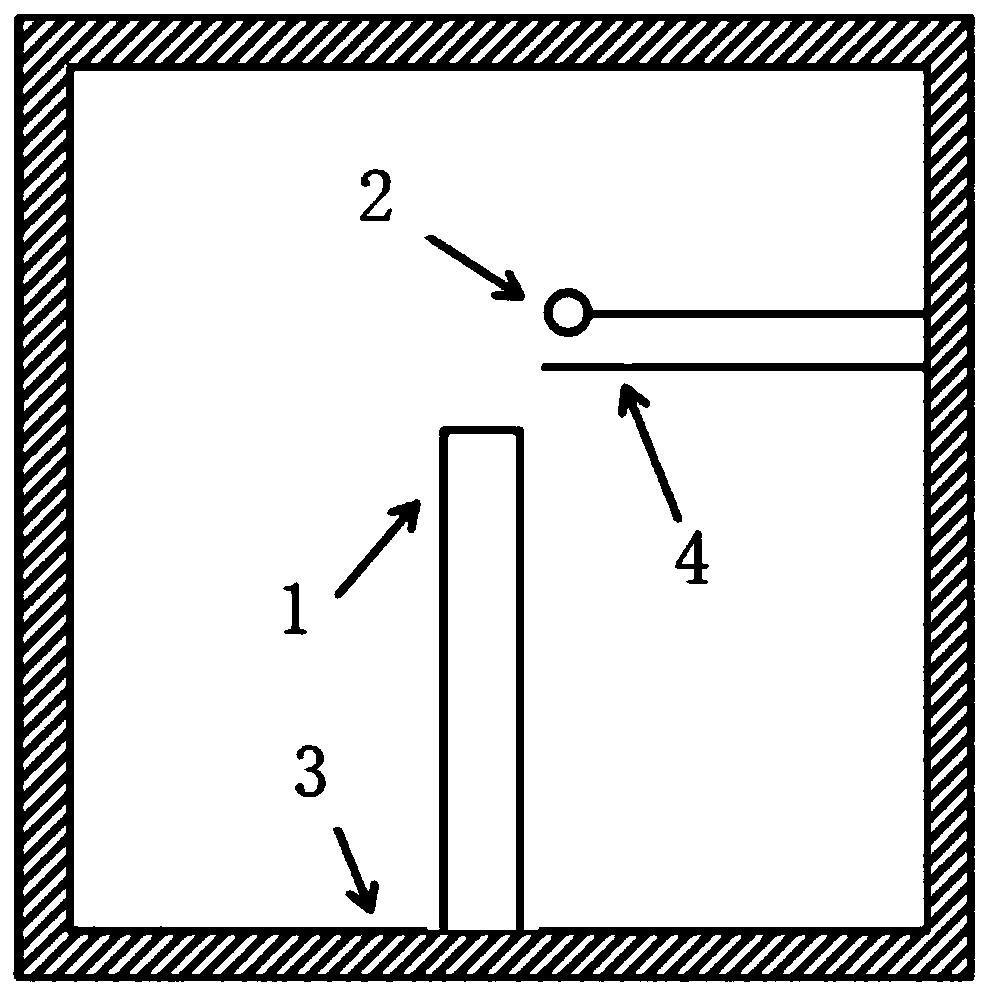

[0023] In a specific embodiment of the present invention, an ultra-stable three-electrode electron beam evaporation source includes: a target 1, a filament 2 and a support base 3; wherein, the target 1 is fixed to the support base 3; the filament 2 It is a high-temperature-resistant metal material, fixed to the support base 3, set above the target 1, and the filament 2 is connected to negative electricity.

[0024] In this specific embodiment, the filament 2 can be made of a high-temperature-resistant metal material, and the main body of the support base 3 can be made of a high-temperature-resistant metal material, or a high-temperature-resistant ceramic material that has high strength, can maintain shape at high temperature, and is insulated. The material can prevent the short circuit of the filament 2 and / or the target 1 connected to the support base 3 from causing the evaporation rate of the evaporation source to be unstable. The filament 2 and the target 1 can be fixed to ...

Embodiment 2

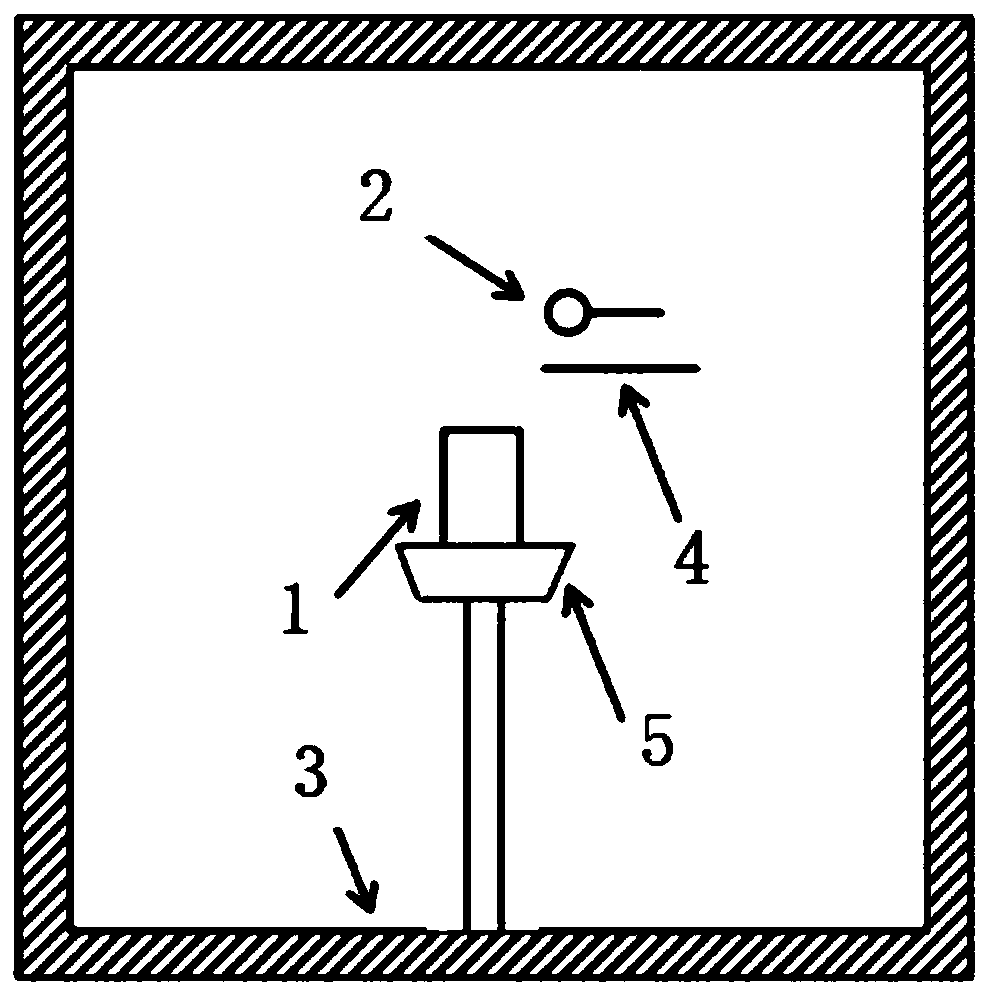

[0038] In a preferred embodiment, an ultra-stable three-electrode electron beam evaporation source, such as figure 2 As shown, the difference from Embodiment 1 is that it further includes a loading crucible 5 , the loading crucible 5 is fixed to the supporting base 3 , and the target 1 is arranged in the loading crucible 5 . When the target material 1 is difficult to be processed into a suitable shape or fixed to the support base 3 , a crucible 5 fixed to the support base 3 may be provided in the evaporation source. The main body of the crucible can be made of high temperature resistant metal materials such as tantalum, molybdenum or tungsten, or high temperature resistant insulating materials such as ceramics. A water cooling device can also be installed inside the crucible to cool the crucible so as to prevent the melting of the crucible from polluting the target 1 or the evaporation of the crucible leading to a decrease in the quality of the steam. It can also reduce the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com