Anti-crystallization hydrophobic modified membrane, and preparation method and application thereof

A hydrophobic modification and anti-crystallization technology, which can be used in general water supply conservation, chemical instruments and methods, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

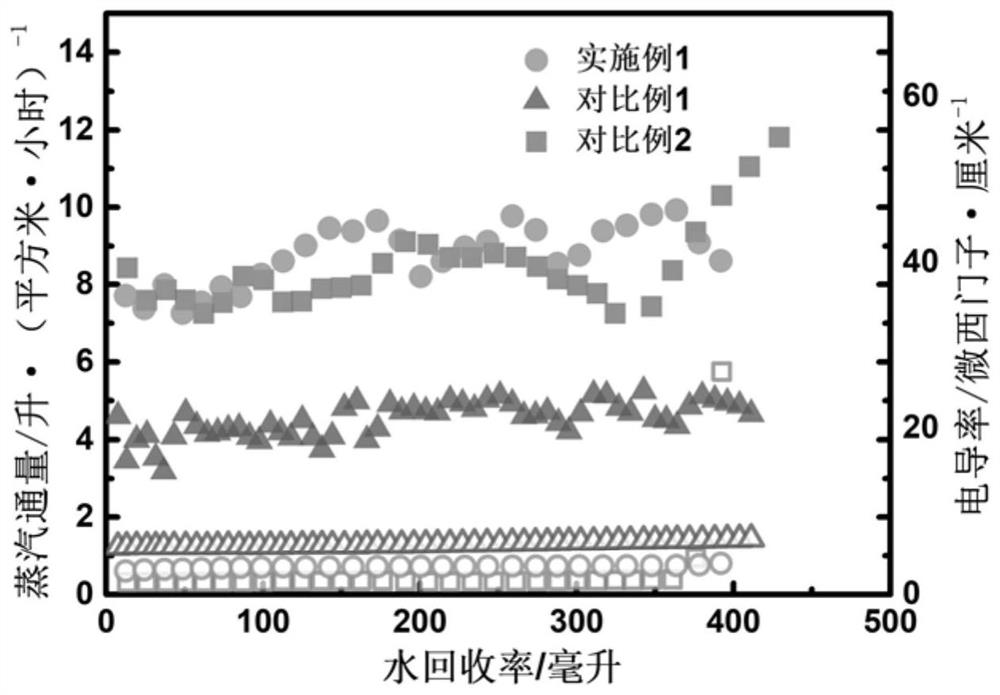

Image

Examples

Embodiment 1

[0034] A method for preparing an anti-crystallization hydrophobically modified film, comprising the steps of:

[0035] S1. Fully dissolve polyvinylidene fluoride in a mixed solution of N,N-dimethylformamide and acetone. The volume ratio of N,N-dimethylformamide and acetone is 2:1 to obtain polyvinylidene fluoride Mass fraction is 13% solution as spinning solution;

[0036] S2. Electrospinning the spinning solution obtained in S1, the conditions are: the voltage is 15kV, the advancing speed is 1mL / h, the temperature is 25°C, and the relative humidity is 30%, to obtain the nanofiber base film;

[0037] S3. Place the nanofiber base film obtained in S2 in the chamber of a plasma surface cleaning machine for surface cleaning, the conditions are: power 150W, time 10min, vacuum degree is -100kPa, and air is introduced;

[0038] S4. Drop 240 μL of N,N-dimethylformamide and 60 μL of perfluoroalkyldimethylchlorosilane on the bottom of a sealable container, and then place the basement m...

Embodiment 2

[0040] The difference from Example 1 is that in this example, the base film obtained in step S3 was treated for 4 hours in an atmosphere where 255 μL of N,N-dimethylformamide and 45 μL of perfluoroalkyldimethylchlorosilane were heated and volatilized. , The volume ratio of N,N-dimethylformamide to perfluoroalkyldimethylchlorosilane is 17:3.

Embodiment 3

[0042] The difference from Example 1 is that this example uses 225 μL of N,N-dimethylformamide and 75 μL of perfluoroalkyldimethylchlorosilane; N,N-dimethylformamide and perfluoroalkyl The volume ratio of dimethylchlorosilane is 15:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com