Rolled reverse osmosis element and preparation method thereof

A technology of reverse osmosis and reverse osmosis membrane, which is applied in the direction of reverse osmosis, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc. It can solve the problems of surface pollution of membrane elements, achieve the effect of reducing pollution speed and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the roll-type reverse osmosis element and its preparation method of the present invention clearer, the present invention will be further described in detail below in conjunction with specific drawings and specific examples.

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

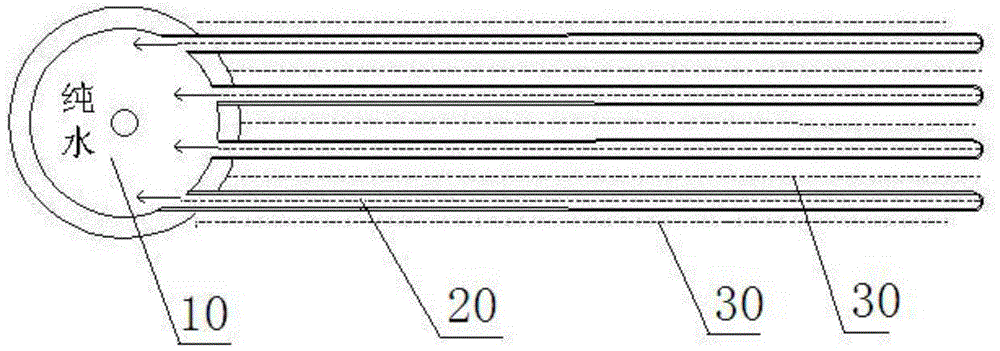

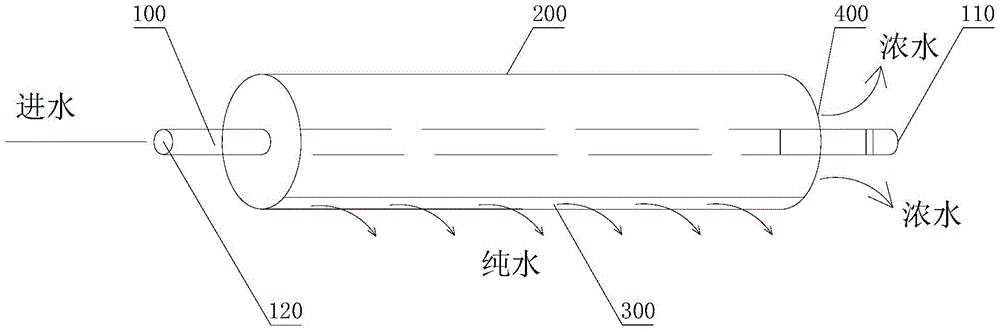

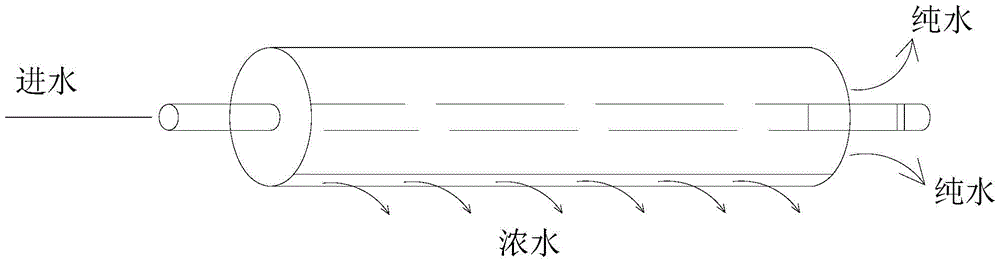

[0031] see figure 1 , the raw water in the existing roll-type reverse osmosis element enters from one end of the entire reverse osmosis element and flows along the water inlet diversion net 30. The water diversion network 20 is collected into the central pipe 10, wherein the central pipe 10 is a water production pipe, and the central pipe 10 is mainly used to collect the produced water, that is, pure water; outflow from the end face. The water inlet direction of this reverse osmosis element is consistent with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com